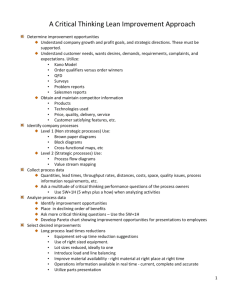

Presentation ()

advertisement

Manufacturing System Design for High Product Quality Jingshan Li, Dennis E. Blumenfeld, Ningjian Huang Robert R. Inman and Samuel P. Marin Manufacturing Systems Research Lab General Motors Research & Development Center Warren, Michigan, USA 5th International Conference on Analysis of Manufacturing Systems May 21 2005 Mayl 2005 • JL • 1 OUTLINE 1. Motivation 2. Manufacturing system design impacts quality 3. Research opportunities 4. Andon System 5. Repair and Rework System 6. Conclusions May 2005 • JL • 2 1. MOTIVATION System design and quality management are important elements in manufacturing industry. Substantial research efforts have been devoted to both of them, but independently. Little research attention has been paid to investigate the interactions between manufacturing system design and product quality. May 2005 • JL • 3 Product Design TQM QFD DFQ Manufacturing System Design Manufacturing System Validation Manufacturing Operation ? TQM Process capability Tolerancing TQM SPC JIT Lot sizing Scarcity of research on attempting to improve quality in manufacturing system design phase Does manufacturing system design impact quality? May 2005 • JL • 4 2. MANUFACTURING SYSTEM DESIGN IMPACTS QUALITY Evidences from automotive industry: Harbour report – quality and productivity are positively correlated → improving production system can improve quality. American Axles & Manufacturing – quality improvement due to production system changes, e.g., conveyor, inspection, buffers, etc. Ford/Jaquar – improve quality by adopting Toyota production systems. GM – strip out buffers to improve paint quality in paint shops. Toyota – pay attention to production system’s impact on quality, e.g., Andon, additional inspection stations, selected stationary assembly stations, etc. May 2005 • JL • 5 Experiments and analysis: Ergonomics – poor workstation layout and high line speeds may hurt quality performance of manual operations. Andon system – stopping the line to fix every problem can improve throughput of good jobs when average repair times are short. Repair and rework system – appropriate design of repair subsystem can improve quality buy rate. Verdict: Manufacturing system design does impact product quality. Largely unexplored area with promising opportunities May 2005 • JL • 6 3. RESEARCH OPPORTUNITIES Strategic issues: Flexibility Agility Level of automation Modularity Outsourcing Scalability Emerging Technology Tactic issues: Andon Assembly Line Movement and Balancing Batch Size Buffer Location and Size Centralized/Decentralized Equipment Feedback Loops Inspection Line or Machine Speed Parallel versus Serial lines Plant Layout Repair and rework loops May 2005 • JL • 7 4. ANDON SYSTEM Andon – a visual control device to monitor quality on assembly line. The worker can pull the Andon cord to trigger a light as a call for help, and stop the line if needed to correct the problem. May 2005 • JL • 8 Current literature contains many popular articles that are descriptive or provide qualitative studies of Andon use. It is claimed and taken for granted that, in spite of line stoppages and productivity loss, overall system performance is improved. Why? Under what conditions? May 2005 • JL • 9 Two different Andon strategies: Empower workers to stop the line for every problem, so that all jobs are corrected first time, or Encourage workers to reduce the number of Andon calls, so that line only stops for severe problems. Which one is the right way? May 2005 • JL • 10 WHY? WHEN? HOW? Need for quantitative model to analyze performance of a transfer production line with Andon. discover the conditions for successful Andon use. investigate trade-offs between productivity and quality. May 2005 • JL • 11 Model Formulation m1 mk m2 Andon cord Transfer line with k machines (m1, m2,..., mk) linked to one Andon cord Performance index: Throughput of good quality jobs May 2005 • JL • 12 Type of systems No Andon: Job moves to next machine at end of cycle, no matter whether job has problem or not. Full Andon: If job has problem or is not complete at end of cycle, Andon cord is pulled and line stops to allow extra time for repair (up to a maximum time tm ). Partial Andon: If job has severe problem at end of cycle, Andon cord is pulled and line stops to allow extra time for repair (up to a maximum time tm ). If job has minor problem at end of cycle, job moves to next machine. May 2005 • JL • 13 Assumptions Machines are synchronized (all jobs start work at the same time) with identical cycle time c. At end of cycle, each machine has fixed probability i that job has defect or is not complete. A defective job has probability ai to have a severe defect. Repair (correspondingly, severe repair) times are independent and exponentially distributed with parameters i (correspondingly, i, and i < i), with truncation at maximum time tm. At most one Andon pull per cycle. Independence of operations and quality failures. May 2005 • JL • 14 One-machine case Throughput of good quality job, G 1 c No Andon: G Full Andon: 1 e tm G c ( ) (1 e tm ) Partial Andon: 1 a (1 e tm ) G c (a ) (1 e tm ) May 2005 • JL • 15 Illustration c = 1, = 0.25, a = 0.5 = 0.9, = 0.8 0.8 0.79 Throughput of good jobs, G Full Andon 0.78 (jobs per unit time) 0.77 Partial Andon 0.76 0.75 No Andon 0.74 0.73 0.72 0 1 2 3 4 Maximum extra time for repair, tm May 2005 • JL • 16 5 Illustration Throughput of Good Jobs, G c = 1, = 0.25, a = 0.5 = 0.8, = 0.7 0.8 0.8 0.79 0.79 0.78 0.78 0.77 0.77 Full Andon 0.76 = 0.7, = 0.5 0.76 0.75 No Andon 0.74 No Andon 0.75 0.74 0.73 Full Andon 0.73 0.72 Partial Andon 0.71 0.72 Partial Andon 0.71 0.7 0.7 0 1 2 3 4 5 0 1 Maximum extra time for repair, tm May 2005 • JL • 17 2 3 4 5 Theorem: Under assumptions, If + cµ > 1, then GNo Andon < GPartial Andon < GFull Andon If + c < 1 < + cµ, then GPartial Andon < GNo Andon < GFull Andon If + c < + cµ < 1, then GFull Andon < GNo Andon GPartial Andon < GNo Andon May 2005 • JL • 18 Insights Implementing Andon can improve throughput of good quality jobs when average repair times are short (i.e., when repair rate is high). Partial Andon is never the best strategy. Even when repair times for severe defects are short, Full Andon is better than Partial Andon. Line Condition Best Strategy Short repair times Long repair times Full Andon No Andon May 2005 • JL • 19 Rules of thumb If average repair time is less than the cycle time, then Full Andon will improve throughput of good quality jobs. If average time to repair severe defects is less than the cycle time, then any type of Andon will improve throughput of good quality jobs. It is worth repairing all defects rather than severe ones only. Right way: Stop line for all problems. Toyota: hundreds of Andons per shift with total line stoppage time of 10-15 minutes. May 2005 • JL • 20 Multiple machine case Throughput of good quality job, G k No Andon: GNo Andon (1 ) i i 1 k k k c (1 i ) i (1 i ) i 1 j 1, j i i 1 k k (1 ) (1 e i Full Andon: GFull Andon i 1 i 1 itm i k ) (1 ) i j 1, j i 1 e itm c (1 i ) i (1 i ) c i i 1 i 1 j 1, j i k k k k k (1 ) a (1 e i Partial Andon: GPartial Andon i 1 i 1 i i i t m k ) (1 ) i j 1, j i k k k k k 1 e itm c (1 i ) i (1 i ) ia i (1 i ) i i 1 j 1, j i j 1, j i i 1 i 1 May 2005 • JL • 21 Throughput of good quality job, G No Andon: Full Andon: Partial Andon: 1 G c1 k G G 1 k (1 e tm ) c1 k k (1e tm ) 1 ka (1 e tm ) c1 k ka (1e May 2005 • JL • 22 tm ) k = 5, c = 1, = 0.1, a = 0.5 = 0.9, = 0.8 Illustration 0.74 0.72 Full Andon 0.7 Throughput of good jobs, G (jobs per unit time) 0.68 Partial Andon 0.66 No Andon 0.64 0.62 0.6 0 1 2 3 4 Maximum extra time for repair tm Right way: Stop line for all problems. May 2005 • JL • 23 5 5. REPAIR AND REWORK SYSTEM Repair and rework systems are often used in many manufacturing industries: automotive, electronics, packaging, process, etc. In automotive assembly plants, product quality is typically characterized by First Time Quality (FTQ): good job ratio of all first time processed jobs Quality Buy Rate (QBR): good job ratio of all jobs, including first time jobs and reworked jobs. May 2005 • JL • 24 Layout New Jobs Inspection Confirmation (OK Jobs) Main Line Component Replacement Rework Minor Repair May 2005 • JL • 25 Quality buy rate (Q): nq1 nr qr Q , n nr where n and nr are the numbers of first time jobs and reworked jobs, respectively, q1 and qr are first time quality and rework quality, respectively. May 2005 • JL • 26 Observations: Minor repair capacity is limited. Jobs that only need minor repair will be routed to rework when the minor repair capacity is insufficient. Often qr < q1. When qr < q1, we obtain Q < q1. When minor repair capacity is insufficient, rerouting the jobs needing minor repair to rework reduces the quality buy rate of the main line. In addition, it will waste more materials and resources and lead to loss of throughput. May 2005 • JL • 27 Need for a quantitative model to analyze quality buy rate as a function of minor repair capacity Analysis results show that quality buy rate can be improved by appropriate design of minor repair capacity The study has been applied in an automotive paint shop May 2005 • JL • 28 nq n(q qr )(1 a x xg ) Nqr ( sg sx xg ) n(1 q )a r ' , if N , n n ( q q )( 1 a ) N ( ) 1 ( 1 q ) a ' r x xg sg sx xg r r Q q (q qr )a r ' n(1 q )a r ' , if N , 1 ( q q ) a ' 1 ( 1 q ) a ' r r r r n(1 q)a r ' na s ' (1 q ) N [1 (1 qr )a r ' ] ( 1 ), if N , ss sx xs 1 (q qr )(1 a x xg ) 1 (1 qr )a r ' na n(1 q)a r ' 0 , if N , 1 ( 1 q ) a ' r r a s a x xs where as ' , 1 ss sx xs ar ' ar a s ( sr sx xr ) a x ( xr xs sr ss xr ) . 1 ss sx xs May 2005 • JL • 29 Illustration: FTQ QBR May 2005 • JL • 30 6. CONCLUSIONS Quality is critical. Manufacturing system design does have a significant impact on product quality. Need to fully understand how it impacts quality and how to incorporate quality with productivity and flexibility in making manufacturing system design choices. Lack of research makes it be a largely unexplored area with promising research opportunities, valued and important to industry. Need to motivate research in the interactions between manufacturing system design and product quality. It will open a new area of manufacturing systems engineering. May 2005 • JL • 31 Thanks Prof. Chris Papadopoulos Prof. Semyon Meerkov Prof. Stanley Gershwin May 2005 • JL • 32 Backups May 2005 • JL • 33 Assembly line movement – how assembly line progress likely affects quality as well as throughput. Synchronous or asynchronous line? Stationary station or continuous moving line? Assembly line balancing – not only from the point of view of worker utilization, but also to identify quality bottlenecks. Plant layout – how layout affects quality? e.g., U - shaped lines produce better quality products. Number and location of inspection stations – integrated quality and productivity model, information feedback, etc. Number and location of rework loops – more rework loops or less? What should capacity of each be? Feedback loops – feedback from inspection, production data analysis, etc. May 2005 • JL • 34 Buffer location and size – buffer accommodate variation, lean inventory contributes to quality, what are tradeoffs? Parallel versus serial lines – Parallel line improves productivity, but increases variations. It is difficult to trace root cause, but it may help quality due to slower speed. Centralize versus decentralized equipment – centralized operations benefit from economic scale, better utilization and is easier for quality control, decentralized operations are responsible for dedicated assembly plants, have less logistic cost, less inventory and quicker feedback from assembly. Batch size – large batch may improve quality by avoiding disruptive changeovers, small batch sizes allow quick defect detection but have frequent changeovers. May 2005 • JL • 35 Flexibility – e.g.: fixtures on machines (loading/unloading) or on conveyors (improve throughput but more variability and degraded repeatability and reproducibility), need to delineate tradeoffs between cost, flexibility, throughput and quality for different strategies. Agility – producing multiple products add variability which may damage quality, machine maintenance may require highly trained labors to obtain high quality, need to achieve both agility and quality without huge investment. Level of automation – automatic operation provides better quality, manual has more flexibility, need to understand impact of automation on productivity, quality and flexibility. May 2005 • JL • 36 Scalability – capacity expansion by speeding up or adding new machines or plants? Single large machines/plants or many small ones? Modularity – easier for final assembler, but difficult to control, what is the impact on quality? Outsourcing – American automakers spin off parts divisions, Toyota rarely hands complex modules to outside suppliers due to quality concerns. Emerging technology – how to take advantage of data collection, communication, analysis capabilities and intelligent agents to design production system for improved quality? May 2005 • JL • 37 k No Andon GNo Andon (1 ) i i 1 k k k c (1 i ) i (1 i ) i 1 j 1, j i i 1 k k (1 ) (1 e i Full Andon GFull Andon i 1 i 1 itm i k ) (1 ) i j 1, j i 1 e itm c (1 i ) i (1 i ) c i i 1 i 1 j 1, j i k k k k k (1 ) a (1 e i Partial Andon GPartial Andon i 1 i 1 i i i t m k ) (1 ) i j 1, j i k k k k k 1 e itm c (1 i ) i (1 i ) ia i (1 i ) i i 1 j 1, j i j 1, j i i 1 i 1 May 2005 • JL • 38 1 GNo Andon . 1 k M No Andon Full Andon GFull Andon 1 k ke tm 1 k Partial Andon , 1 1 e t m c c kc k 1 k , k[2(1 k )(1 e tm t m e tm ) k (1 e tm ) 2 ] c c kc k (1 e tm ) GPatial Andon where T CV M 1.67( M 1)CV T 1 1 M 0.31CV 1.67 MN 2CV where T CV 1 ka kae tm 1 k . M 1.67( M 1)CV T 1 1 M 0.31CV 1.67 MN 2CV , 1 1 e tm c c kc ka 1 k , ka [2(1 k )(1 e tm t me tm ) ka (1 e tm ) 2 ] . c c kc ka (1 e tm ) May 2005 • JL • 39 0.8 0.79 0.78 0.77 0.76 0.75 0.74 0.73 0.72 3. 6 4. 2 4. 8 3 System with no Andon System with full Andon System with partial Andon 0. 6 1. 2 1. 8 2. 4 0 0.9 1.2 Good Production Rate One machine system t_m May 2005 • JL • 40 0.8 0.79 0.78 0.77 0.76 0.75 0.74 0.73 0.72 3. 6 4. 2 4. 8 3 System with no Andon System with full Andon System with partial Andon 0. 6 1. 2 1. 8 2. 4 0 0.85 0.9 Good Production Rate One machine system t_m May 2005 • JL • 41 0.8 0.79 0.78 0.77 0.76 0.75 0.74 0.73 0.72 3. 6 4. 2 4. 8 3 System with no Andon System with full Andon System with partial Andon 0. 6 1. 2 1. 8 2. 4 0 0.7 0.9 Good Production Rate One machine system t_m May 2005 • JL • 42 0.8 0.79 0.78 0.77 0.76 0.75 0.74 0.73 0.72 3. 6 4. 2 4. 8 3 System with no Andon System with full Andon System with partial Andon 0. 6 1. 2 1. 8 2. 4 0 0.7 0.8 Good Production Rate One machine system t_m May 2005 • JL • 43 Theorem: Under assumptions, If (k-1)cµ + + cµ > 1, then GNo Andon < GPartial Andon < GFull Andon If (k-1)c + + c < 1 < (k-1)cµ + + cµ, then GPartial Andon < GNo Andon < GFull Andon If (k-1)c + + c < (k-1)cµ + + cµ < 1, then GFull Andon < GNo Andon GPartial Andon < GNo Andon May 2005 • JL • 44 Rules of thumb If average repair time is less than cycle time plus average time within a cycle working on defective jobs, Full Andon improves throughput of good quality jobs. If average time to repair severe defects is less than cycle time plus average time within a cycle working on defective jobs, then any type of Andon will improve throughput of good quality jobs. It is worth repairing all defects rather than severe ones only. Right way: Stop line for all problems. May 2005 • JL • 45 Extensions Non-identical machines System with multiple Andon cords Andon cord Buffer May 2005 • JL • 46 Andon cord Assumptions: A job can be reworked/repaired multiple times. No scrap. Constant percentages of good quality jobs. All reprocessed jobs have identical good job ratio. All routing probabilities are constants. Notation: αx, αr, αs: routing probabilities after main line inspection. βsx, βss, βsr, βxs, βxr: routing probabilities after minor repair and component exchange. N: minor repair capacity.. May 2005 • JL • 47 Need to develop a quantitative model to analyze quality buy rate as a function of minor repair capacity design appropriate repair capacity to achieve desired quality buy rate investigate the trade-offs between investment costs and saving from productivity and quality improvement May 2005 • JL • 48 Theorem: Under assumption, the quality buy rate can be calculated as: nq n(q qr )(1 a x xg ) Nqr ( sg sx xg ) , if n n(q qr )(1 a x xg ) N ( sg sx xg ) Q q (q qr )a r ' , if 1 (q qr )a r ' N n(1 q )a r ' , 1 (1 qr )a r ' N n(1 q )a r ' . 1 (1 qr )a r ' a s a x xs , where 1 ss sx xs a ( sx xr ) a x ( xr xs sr ss xr ) a r ' a r s sr . 1 ss sx xs as ' May 2005 • JL • 49 Corollary: Under assumptions, the quality buy rate is monotonically increasing with respect to q, qr and N (when minor repair capacity is insufficient). FTQ QBR May 2005 • JL • 50 Corollary: Under assumptions, the number of rerouted jobs can be calculated as: na s ' (1 q) N [1 (1 qr )a r ' ] (1 ss sx xs ), if 1 (q qr )(1 a x xg ) na 0, if May 2005 • JL • 51 N n(1 q)a r ' , 1 (1 qr )a r ' N n(1 q)a r ' . 1 (1 qr )a r ' Corollary: Under assumptions, the number of rerouted jobs is monotonically decreasing with respect to q, qr and N (when the minor repair capacity is insufficient). May 2005 • JL • 52