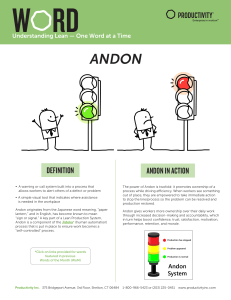

Andon feature added for visual monitoring

advertisement

From: John Rubio [mailto:johnr@simpler.com] Sent: Thursday, August 14, 2008 3:44 PM To: S Chandler Subject: Re: SMED - CoP Solutions/Tools Try Pro Andon on the web. They do this type of Of thing Thanks From: John Rubio [mailto:johnr@simpler.com] Sent: Thursday, August 14, 2008 3:44 PM To: S Chandler Subject: Re: SMED - CoP Solutions/Tools http://www.manufacturingtalk.com/ news/ott/ott101.html: Click on the advert above to visit the company web site Product category: Plant and shopfloor scheduling software News Release from: Orbit Technology Corporation | Subject: Virtual Factory software Edited by the Manufacturingtalk Editorial Team on 30 October 2003 Andon feature added for visual monitoring Request your FREE weekly copy of the Manufacturingtalk email newsletter. News about Plant and shopfloor scheduling software and more every issue. Click here for details. Orbit Technology Corporation has added an andon (pronounced ahn-dohn) feature to Virtual Factory, allowing factory supervisors to more easily monitor factory status. Orbit Technology Corporation has added an andon (pronounced ahn-dohn) feature to Virtual Factory, allowing factory supervisors to more easily monitor factory status Virtual Factory, the "monitoring and control" software solution from Orbit Technology Corporation, has added an andon feature to its long list of product features This article was originally published on Manufacturingtalk on 7 Aug 2003 at 8.00am (UK) Related stories Monitor and control machines in real time remotely Virtual Factory provides a flexible, virtual representation of manufacturing facilities that enables monitoring and control of machines and devices via the Internet. DNC interface gives direct machine status reports Programmable DNC interface allows users to receive automatic notifications via mobile phone, e-mail, or status panel based upon changes in states of DNC-controlled machines. Andon became popular in the late 1980's in Japan and elsewhere as a component of the just-intime (JIT) manufacturing philosophy. Traditional andon systems consist of a panel of lights, each of which are connected to machines and devices located on the factory floor. Whenever the state of a machine or device changes (e.g., in operation, not in operation, jammed, etc.), the andon panel gives managers an immediate, visual update regarding the change. Further reading Share and annotate CAD files via the Internet Share, mark-up, and annotate almost any 2D or 3D CAD file type with remote partners or clients via the Internet with this professional grade collaborative visualization tool. Share and annotate CAD files via the Internet Share, mark-up, and annotate almost any 2D or 3D CAD file type with remote partners or clients via the Internet with this professional grade collaborative visualization tool. Extending automation reach and functionality An enhancement to a distributed control system gives manufacturing personnel access to customised information according to their job function. Unlike traditional andon systems using light bulbs hard-wired to machines, Virtual Factory's andon feature works through any computer video monitor. The display is user-configurable, including the number, size, and color of andon lights, as well as device names to be monitored. Most important, the user can add new physical devices at any time and determine the circumstances under which the device should alert managers via the andon display. All of these configurations are carried out within the Virtual Factory environment, so hardwiring alterations are usually not necessary. About Virtual Factory - Virtual Factory gives users the power to monitor and control any machine or device in their factory from any place with an Internet connection. It treats each real-world machine, device, and worker in the facility as a virtual object that can be viewed or controlled using an ergonomic user interface. Data constantly flows between Virtual Factory and machines/devices/ workers in the factory in real time. The software can poll the current status of machines, PLCs, RTUs, HVAC systems, and workers every few seconds and then keep track of data about their activities in a data log for future reference. The data can also be used to instantly trigger actions by other devices. Alerts can be sent to managers via telephone, e-mail, or pager about problem situations. The software can automatically carry out video monitoring and recording tasks and can accommodate Ethernet or USB-based cameras with built-in buffering capabilities. Virtual Factory can interface with any number of external software modules, including scheduling and nesting programs. It can be configured to interface with any digital or analog input/output device. Sample Applications * Program Virtual Factory to automatically call your cell phone to alert you that a machine scheduled to run until 3:30 a.m. actually stopped at 1:14 a.m. * Check in on remotely located workers via video link or digital monitoring device to be sure they are following proper safety procedures. * Run a report based on log data that lists all start/stop times for a particular machine over a twoweek period in order to determine optimal usage patterns. * Set up Virtual Factory to automatically track and monitor the status of each stage of a laser cutting process for sheet metal - from nesting to scheduling to cutting - to ensure on-schedule operation. * Have Virtual Factory send an alert to the cell phone of security personnel whenever someone is detected entering your facility without the proper RFID-equipped badge. * Program Virtual Factory to e-mail the shop floor manager with an MPEG or AVI file containing video footage of the machine immediately before and after an unscheduled stoppage occurred. 10/28/2003. • Orbit Technology Corporation: contact details and other news • Email this article to a colleague • Register for the free Manufacturingtalk email newsletter • Manufacturingtalk Home Page Search the Pro-Talk network of sites Search > xml_no_dtd pro-talk pro-talk pro-talk Read our new 2008 Media Pack Put your news on Manufacturingtalk | Advertise | Get the free Manufacturingtalk newsletter | Manufacturingtalk Home About Manufacturingtalk | Copyright © 2000-2008 Pro-Talk Ltd, UK ANOTHER SOURCE FROM THE WEB: http://www.london-electronics.com/andondisplays.php Andon Displays Made to measure Andon displays Andon displays help you to identify where you need to concentrate your efforts, to get maximum efficiency from your lines. Because every line is different, with different factors affecting productivity, all our Andon displays are custom made to suit your exact needs. This is a typical andon display for a 24 hour, 5 line production plant. It has a lot of useful information which is easy to understand at a glance. The digit height can be 57mm, 102mm, 144mm, 200mm or 280mm. This allows for clear viewing distances up to 130 metres. We know what each shift's target output should be. We can see what each shift has achieved. We can see line 5 has stopped We can see lines 2 and 3 are running slow We can see lines 1 and 4 are running OK See video of a single andon annunciator module in operation... The enclosures are sealed and contain all the necessary power and signal processing boards. They can be wall or suspension mounted, and run from 11-30VDC or 95-265 VAC. All use long-life, low maintenance LED's for trouble-free operation over many years. Feel welcome to tell us what you need and we'll get a quote off to you by return. Here are a few more examples of production displays you may find of interest.