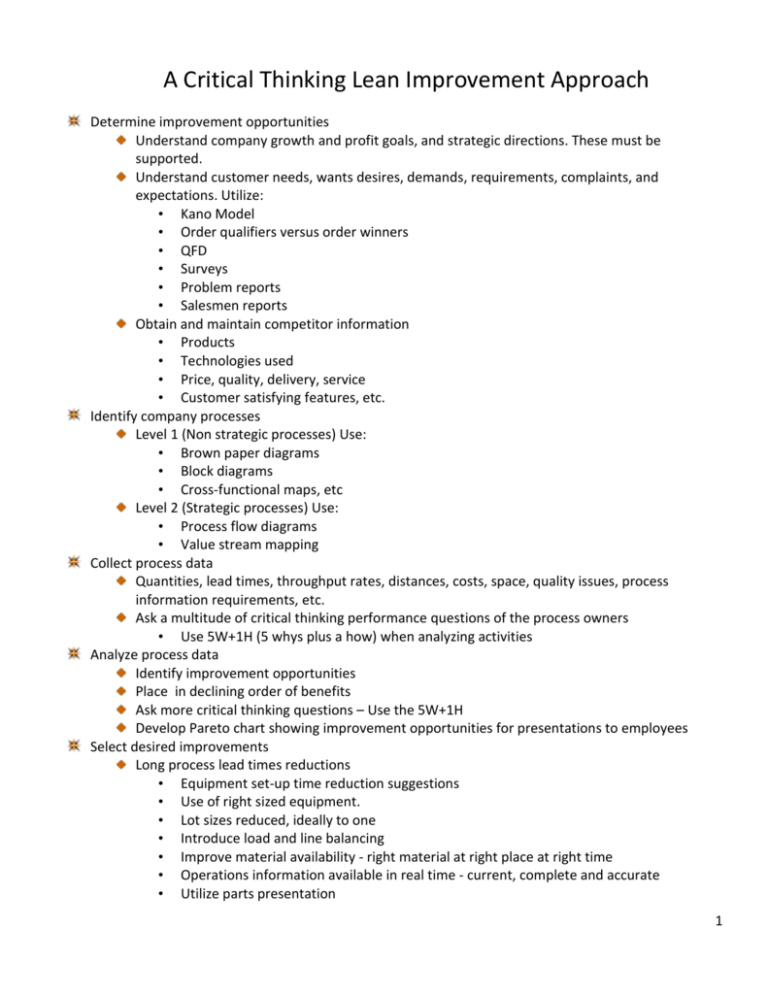

A Critical Thinking Lean Improvement Approach

advertisement

A Critical Thinking Lean Improvement Approach Determine improvement opportunities Understand company growth and profit goals, and strategic directions. These must be supported. Understand customer needs, wants desires, demands, requirements, complaints, and expectations. Utilize: • Kano Model • Order qualifiers versus order winners • QFD • Surveys • Problem reports • Salesmen reports Obtain and maintain competitor information • Products • Technologies used • Price, quality, delivery, service • Customer satisfying features, etc. Identify company processes Level 1 (Non strategic processes) Use: • Brown paper diagrams • Block diagrams • Cross-functional maps, etc Level 2 (Strategic processes) Use: • Process flow diagrams • Value stream mapping Collect process data Quantities, lead times, throughput rates, distances, costs, space, quality issues, process information requirements, etc. Ask a multitude of critical thinking performance questions of the process owners • Use 5W+1H (5 whys plus a how) when analyzing activities Analyze process data Identify improvement opportunities Place in declining order of benefits Ask more critical thinking questions – Use the 5W+1H Develop Pareto chart showing improvement opportunities for presentations to employees Select desired improvements Long process lead times reductions • Equipment set-up time reduction suggestions • Use of right sized equipment. • Lot sizes reduced, ideally to one • Introduce load and line balancing • Improve material availability - right material at right place at right time • Operations information available in real time - current, complete and accurate • Utilize parts presentation 1 • Implement pull systems and Kanban approaches • Secondary benefits may also result such as cost reductions and quality improvements Material and product travel distances reduction • Introduce cellular approach and work areas efficiency layout changes • Use smaller lots of WIP Process variability reduction areas. Utilize Six Sigma techniques • Equipment • Tooling • Material • Equipment set up • Labor • Training • Procedures • Standards Manufacturing errors reduction • Introduce standard procedures • Introduce Polka Yoke devices • Introduce Jidoka (autonomation) Provide current, complete and accurate operations data • Schedule and production status information - planned versus actual • Use visual Andon control boards for production progress and status Assure timely delivery of needed raw materials to work stations Introduce appropriate employee training and education Investigate efficiency improvements in product design, such as use of DFMA • Introduce value engineering • Consider benefits of flattened a bill of material, etc. Investigate efficiency improvements in process design (IPPD) Improve housekeeping by introducing the 5Ss or 6Ss Introduce needed cultural changes oriented towards personal responsibility in daily efforts Assure timely and complete support from other departments Improve schedule stability (minimize schedule changes) • Includes customer order schedules Introduce total productive maintenance (TPM) Introduce Six Sigma Quality improvement methods for reduction of process variability's Develop process performance metrics and share with employees Analyze performance of company's supply chains and improve where necessary Stabilize receipt of customer orders Implement selected approaches to process improvements starting with the most beneficial ones Measure performance of strategic processes periodically, present them to employees, and adjust performance as necessary for continuous improvement Update the list of process improvements on a continuous improvement basis Repeat this entire process periodically. Customer and competitor surveillance should be performed continuously. 2