slides_3e_chp10

advertisement

Matching Supply with Demand:

An Introduction to Operations Management

Gérard Cachon

ChristianTerwiesch

All slides in this file are copyrighted by Gerard Cachon and Christian

Terwiesch. Any instructor that adopts Matching Supply with

Demand: An Introduction to Operations Management as a required

text for their course is free to use and modify these slides as desired.

All others must obtain explicit written permission from the authors to

use these slides.

Slide ‹#›

Quality

Rework

Quality at the Source

Slide ‹#›

Process interruption due to rework

Scan Passenger

Passenger Prep

6

3.4

X-ray items

Retrieve items

4

2.73

Suppose 10% of bins need to be rescanned.

The average activity time to X-ray is then 0.9 x 20 + 0.1 x 40 = 22 secs

X-ray capacity is now 60 / 22 = 2.73 bins per minute.

The bottleneck’s capacity is reduced due to rework!

Hence – avoid sending re-work through the bottleneck!

Slide ‹#›

Batching and quality

= Good unit

A

B

C

= Bad unit

Suppose process A can start making defective units and once it starts to make

defective units it does so until corrective action is taken,

Suppose quality inspection to discover defective units is only done at process

step C.

With two units allowed in the buffers, there will be four defective units made

before the problem is discovered.

Slide ‹#›

Quality at the source

A

B

C

= Good unit

= Bad unit

But with 6 units allowed in the buffer, there will be 12 defective units before

the problem is discovered!

Hence:

Large batches are problematic when quality is an issue.

Large batches can lead to lots of wasted capacity – imagine if step B were

the bottleneck!

Firms should adopt “quality at the source” whenever possible:

Inspect for quality when an item is produced.

Inspect the 1st item in a batch rather than inspecting only when the

batch is completed.

Inspecting for quality is most valuable in front of the bottleneck.

Slide ‹#›

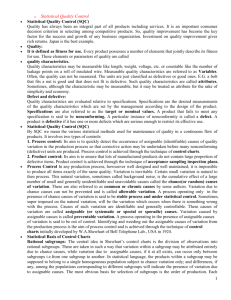

Quality and Six Sigma

Slide ‹#›

M&M Exercise

Form groups around a scale and a sample of M&M bags

A bag of M&M’s should be between 48 and 52g

Measure the samples on your table:

Compute x1, x2, x3, x4, x5

Compute x-bar and range (R)

Number of defects

All data will be compiled in master spread sheet

Yield = %tage of units according to specifications

How many defects will we have in 1MM bags?

Analysis of new sample in production environment

Slide ‹#›

Measure Process Capability:

Quantifying the Common Cause Variation

Process capability measure

Upper

Specification

Limit (USL)

Lower

Specification

Limit (LSL)

Process A

(with st. dev A)

X-3A

X-2A

X-1A

X

X+1A X+2

X+3A

3

Process B

(with st. dev B)

X-6B

X

Cp

USL LSL

6ˆ

x

Cp

P{defect}ppm

1

0.33

0.317

317,000

2

0.67

0.0455

45,500

3

1.00

0.0027

2,700

4

1.33

0.0001

63

5

1.67

0.0000006

0,6

6

2.00

2x10-9

0,00

X+6B

• Estimate standard deviation in excel

• Look at standard deviation relative to specification limits

• Don’t confuse control limits with specification limits: a process can be in

control, yet be incapable / out of control, butSlide

still

capable

‹#›

Two Types of Variation

Common Cause Variation (low level)

Common Cause Variation (high level)

Assignable Cause Variation

• Need to measure and reduce common cause variation

• Identify assignable cause variation as soon as possible

• What is common cause variation for one person might be

assignable cause to the other Slide ‹#›

Two (similar) Frameworks for Managing Quality

Toyota Quality System

Six Sigma System

Jidoka

Andon cord

Detect,

stop,

alert

Avoid

Rootcause

problemsolving

Poka Yoke

Ishikawa Diagram

Build-in quality

Kaizen

Capability

Analysis

Conformance

Analysis

Eliminate

Assignable

Cause

Investigate for

Assignable

Cause

Some commonalities:

Avoid defects by keeping variation out of the process

If there is variation, create an alarm and trigger process improvement actions

The process is never perfect – you keep on repeating these cycles

Slide ‹#›

Detect Abnormal Variation in the Process:

Detect – Stop - Alert

Jidoka

If equipment malfunctions / gets out of control,

it shuts itself down automatically to prevent

further damage

Requires the following steps:

Detect

Alert

Stop

Andon Board / Cord

A way to implement Jidoka in an assembly line

Make defects visibly stand out

Once worker observes a defect, he shuts down the

line by pulling the andon / cord

The station number appears on the andon board

Source: www.riboparts.com, www.NYtimes.com

Slide ‹#›

Detect Abnormal Variation in the Process:

Identifying Assignable Causes

• Track process parameter over time

- mean

- percentage defects

Process

Parameter

Upper Control Limit (UCL)

• Distinguish between

- common cause variation

(within control limits)

- assignable cause variation

(outside control limits)

Center Line

Lower Control Limit (LCL)

Time

• Measure process performance:

how much common cause variation

is in the process while the process

is “in control”?

Slide ‹#›

Root Cause Problem Solving

Ishikawa Diagram

A brainstorming technique of what might have

contributed to a problem

Pareto Chart

Maps out the assignable causes of a problem in the

categories of the Ishikawa diagram

Shaped like a fish-bone

Order root causes in decreasing order of frequency

of occurrence

Easy to use

80-20 logic

Slide ‹#›

Quality Management: Conclusion

Variation (once again) is the root cause for all operational problems

Difference between common cause variation and assignable causes

Quality and flow are tightly related

Toyota Production System (TPS) provides an integrated framework of managing

quality AND flow

Strong similarities between Six Sigma and TPS

Measure and reduce the common cause variation

Build processes that are robust to variation / operators (poka-yoke)

Detect assignable causes through control charts

Detect - Stop – Alert (Jidoka, Andon Cord)

Root cause problem solving (Ishikawa, Pareto)

Slide ‹#›