PART A LEAN 7typesofwaste: üOverproduction

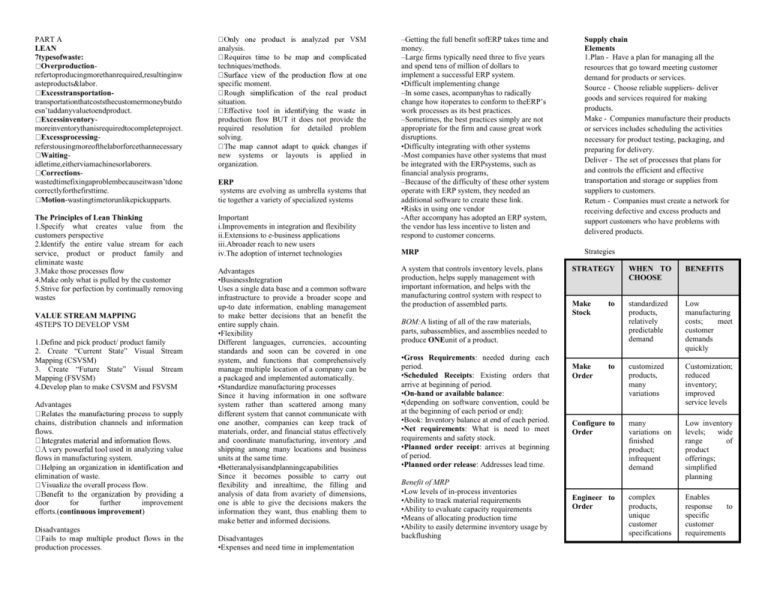

advertisement

PART A LEAN 7typesofwaste: Overproductionrefertoproducingmorethanrequired,resultinginw asteproducts&labor. Excesstransportationtransportationthatcoststhecustomermoneybutdo esn’taddanyvaluetoendproduct. Excessinventorymoreinventorythanisrequiredtocompleteproject. Excessprocessingreferstousingmoreofthelaborforcethannecessary Waitingidletime,eitherviamachinesorlaborers. Correctionswastedtimefixingaproblembecauseitwasn’tdone correctlyforthefirsttime. Motion-wastingtimetorunlikepickupparts. The Principles of Lean Thinking 1.Specify what creates value from the customers perspective 2.Identify the entire value stream for each service, product or product family and eliminate waste 3.Make those processes flow 4.Make only what is pulled by the customer 5.Strive for perfection by continually removing wastes VALUE STREAM MAPPING 4STEPS TO DEVELOP VSM 1.Define and pick product/ product family 2. Create “Current State” Visual Stream Mapping (CSVSM) 3. Create “Future State” Visual Stream Mapping (FSVSM) 4.Develop plan to make CSVSM and FSVSM Advantages chains, distribution channels and information flows. used in analyzing value flows in manufacturing system. elimination of waste. door for further improvement efforts.(continuous improvement) analysis. techniques/methods. specific moment. situation. production flow BUT it does not provide the required resolution for detailed problem solving. new systems organization. or layouts is applied ERP systems are evolving as umbrella systems that tie together a variety of specialized systems Important i.Improvements in integration and flexibility ii.Extensions to e-business applications iii.Abroader reach to new users iv.The adoption of internet technologies Advantages •BusinessIntegration Uses a single data base and a common software infrastructure to provide a broader scope and up-to date information, enabling management to make better decisions that an benefit the entire supply chain. •Flexibility Different languages, currencies, accounting standards and soon can be covered in one system, and functions that comprehensively manage multiple location of a company can be a packaged and implemented automatically. •Standardize manufacturing processes Since it having information in one software system rather than scattered among many different system that cannot communicate with one another, companies can keep track of materials, order, and financial status effectively and coordinate manufacturing, inventory ,and shipping among many locations and business units at the same time. •Betteranalysisandplanningcapabilities Since it becomes possible to carry out flexibility and inrealtime, the filling and analysis of data from avariety of dimensions, one is able to give the decisions makers the information they want, thus enabling them to make better and informed decisions. Disadvantages production processes. in Disadvantages •Expenses and need time in implementation –Getting the full benefit sofERP takes time and money. –Large firms typically need three to five years and spend tens of million of dollars to implement a successful ERP system. •Difficult implementing change –In some cases, acompanyhas to radically change how itoperates to conform to theERP’s work processes as its best practices. –Sometimes, the best practices simply are not appropriate for the firm and cause great work disruptions. •Difficulty integrating with other systems -Most companies have other systems that must be integrated with the ERPsystems, such as financial analysis programs, –Because of the difficulty of these other system operate with ERP system, they needed an additional software to create these link. •Risks in using one vendor -After accompany has adopted an ERP system, the vendor has less incentive to listen and respond to customer concerns. Supply chain Elements 1.Plan - Have a plan for managing all the resources that go toward meeting customer demand for products or services. Source - Choose reliable suppliers- deliver goods and services required for making products. Make - Companies manufacture their products or services includes scheduling the activities necessary for product testing, packaging, and preparing for delivery. Deliver - The set of processes that plans for and controls the efficient and effective transportation and storage or supplies from suppliers to customers. Return - Companies must create a network for receiving defective and excess products and support customers who have problems with delivered products. MRP Strategies A system that controls inventory levels, plans production, helps supply management with important information, and helps with the manufacturing control system with respect to the production of assembled parts. STRATEGY WHEN TO CHOOSE BENEFITS Make Stock to standardized products, relatively predictable demand Low manufacturing costs; meet customer demands quickly Make Order to customized products, many variations Customization; reduced inventory; improved service levels Configure to Order many variations on finished product; infrequent demand Low inventory levels; wide range of product offerings; simplified planning Engineer to Order complex products, unique customer specifications Enables response to specific customer requirements BOM:A listing of all of the raw materials, parts, subassemblies, and assemblies needed to produce ONEunit of a product. •Gross Requirements: needed during each period. •Scheduled Receipts: Existing orders that arrive at beginning of period. •On-hand or available balance: •(depending on software convention, could be at the beginning of each period or end): •Book: Inventory balance at end of each period. •Net requirements: What is need to meet requirements and safety stock. •Planned order receipt: arrives at beginning of period. •Planned order release: Addresses lead time. Benefit of MRP •Low levels of in-process inventories •Ability to track material requirements •Ability to evaluate capacity requirements •Means of allocating production time •Ability to easily determine inventory usage by backflushing Benefits Lower inventories Higher productivity Greater agility Shorter lead times Higher profits Greater customer loyalty Preliminary steps in SCM Step 1 – Energize the Organization Step 2 – Enterprise Vision Step 3 – Supply Chain Value Assessment Step 4 – Opportunity identification Step 5 – Strategy Decision Distribution Often called logistics. Movement of materials, services, cash, and information in a supply chain. Two types of logistics: Forward Raw materials, parts and finished goods flowing from suppliers to producers, distributors and, finally, to consumers. Reverse Wastes, packages, and defective/obsolete products are "climbing back" the supply chain. Goal: Recapture/create value in returned goods/to properly dispose of goods that cannot be sold. Warehouse Management Warehouse: Commercial building for storage of goods. Warehouse management to optimize: Inventory Labor Physical Space Time Costs To control the movement and storage of materials within an operation and process the associated transactions. Utilize technology (Barcode scanner, mobile computer, Radio-frequency identification (RFID)