Chapter 13

Systems

Processes

(IPP)

1

Learning Objectives

• Appreciate contemporary production trends.

• Understand role of ERPs in integrating total manufacturing environment.

• Know principal components of Integrated

Production Processes (IPP).

• Recognize effects of automation on IPP.

• Understand key inputs, outputs, files, processes.

• Identify principal challenges/opportunities.

• Introduce supply chain management software

ERPs - SAP Automotive Modules

•

Business Planning

•

Controlling

•

Finance & Accounting

•

Suppliers

•

Original Equipment Manufacturers

•

Aftermarket

3

Managing Throughput Times

•

Push Manufacturing

–

Sales forecast drives production plan

–

Goods produced in large batches

–

Jobs wait until machines ready

•

Pull Manufacturing

–

Idle machine pulls job from previous machine

– Theoretically, job = “batch” of one unit

4

Features of Pull Approach

•

Short production runs

•

Continuous flow operations

•

Factory cells - all machines together

– workers run more than 1 machine

•

Reduced WIP & FG inventories

•

Reduced floor space

– improved layout/less inventory

5

Trends - Cost Management/

Accounting

•

Shift to reporting to assist strategic planning/decision making

•

Increased emphasis - managing costs v. accounting for costs

•

Attack waste Vs. reporting variances

•

Flexible cost systems - responsive to change

•

Shift - cost structure - variable to fixed costs

6

Trends - Cost Management/

Accounting (2)

•

Less DL - less use of DL to apply OH

•

Increase in OH component of total cost

•

4th category (direct technology) added to DM,

DL, OH

•

Use of Activity Based Costing (ABC) systems

•

Real-time data capture in factory

•

Shift from Std. cost systems to actual

•

Reduction in data-gathering costs

•

Collecting statistical + financial data

7

Trends - Cost Management/

Accounting (3)

•

Replace detail reporting by shop order and/or operation with actg. for cell throughput time

•

Use cell throughput time v. DL to apply OH

•

Trend towards process cost systems v. job order systems

•

For mgt. purposes, abandonment of absorption costing

•

Accumulation of costs for decision making vs. valuing inventories

8

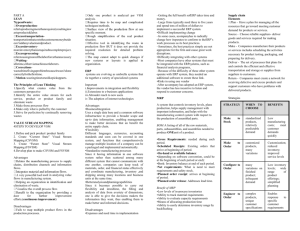

Overview–ERP-Driven Manufacturing

En gi n e e ri n g

ERP Database

Man u factu ri n g

Bu si n e s s

Re porti n g

ERP Data management modules

ERP Data management

Engineering Flexible Manufacturing System Production, Planning and Control

Floor Control

Logistics Process Control and Planning

Product Design

CAM GT

MPS

MRP

MRP SFC

CAD/

CAE

CAPP

CRP DRP

CNC

Robotics

AGVS &

AS/RS

Automated

Data

Collection

Bar code readers

VDTs

JIT

Quality

Management

Business Reporting

OE/S

B/AR/

CR

P/AP/

CD

HR

Product costing

Inventory control

Performance measurement

9

Communication and Messaging (i.e., change orders, new designs, etc.)

Production Planning/Control

Systems

•

Manufacturing Resource Planning (MRP)

–

Master production schedule

–

Materials requirements planning (mrp)

–

Shop floor control

•

Just-in-time

10

Just-in-time Objectives

•

Zero defects

•

Zero setup times

•

Small lot sizes

•

Zero lead times

•

Zero inventories

11

JIT Implementation Features

•

Arrange factory in U-shaped work cells

•

Assign 1 worker to multiple machines

•

Give production workers authority to stop the line if they are behind schedule or if they discover defective parts

•

Require nearly constant parts production schedule

•

Develop vendor cooperation re deliveries

•

Simplify system for tracking movement of goods through factory

12

Flexible Mfg. Systems Components

•

Group Technology

•

Computer-aided manufacturing

•

Computer-aided process planning

– computer numerical control

• robotics

• automated guided vehicles

• automated storage/retrieval systems

• digital image processors

•

Automated data collection devices

13

A

Start

Master production schedule (MPS)

Materials requirements planning

(little mrp)

Parts master

Time-phased order requirements

BOM*

Detailed capacity requirements planning

(DCRP)

Open

MO*

Open

PO*

RM

Status*

FG

Status*

Time-phased order requirements

A

Released

POs

Production schedule

Routing*

Work center master*

Work center status*

Raw materials requisitions

Completed move tickets

Production work centers

Job time tickets

Shop floor control (SFC)

Cost accounting

Open

MO*

Overview: Production planning & control & cost accounting.

Vendors

Production supervisor

Inventory control

Completed mfg. orders notice

Released mfg. orders

Printed move tickets

Production work centers

Cost variances

GL updates

Various managers

RM issued notice

Inventory control RM returned notice

Standard costs master*

WIP

Inventory*

General

Ledger*

Budget master*

Payroll master*

GL system

BOM = Bill of materials; MO = Manufacturing orders; PO = Purchase orders; RM = Raw materials; WIP =

Work in Process; FG = Finished Goods * = ERP database component

14

15

16

17

18

19

Inventory system controls

•

Effectiveness of operations

– maintain sufficient inventory to prevent stockouts

– maintain sufficient inventory to maintain operational efficiency

– minimize cost of carrying inventory

•

Efficiency of system operations

– JIT materials acquisition

–

Warehouse bin locations

•

Resource security

– periodic physical inventory counts

– locked storerooms

20

Learning Objectives

• Appreciate contemporary production trends.

• Understand role of ERPs in integrating total manufacturing environment.

• Know principal components of Integrated

Production Processes (IPP).

• Recognize effects of automation on IPP.

• Understand key inputs, outputs, files, processes.

• Identify principal challenges/opportunities.

• Introduce supply chain management software