CT QUALITY MANAGEMENT

advertisement

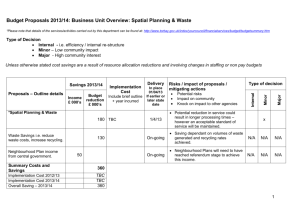

CT QUALITY MANAGEMENT SPATIAL RESOLUTION CONTRAST RESOLUTION RADIATION DOSE NOISE IMAGE ARTIFACTS TESTS • • • • • • AVERAGE CT NUMBER AND NOISE CROSS-FIELD UNIFORMITY SPATIAL RESOLUTION LOW CONTRAST RESOLUTION SLICE THICKNESS LASER LIGHT ACCURACY NOISE IN CT • FLUCTUATION OF CT# BETWEEN POINTS IN THE IMAGE FOR A SCAN OF UNIFORM MATERIAL SUCH WATER. NOISE CAN BE MEASURED BY SCANNING A WATER PHANTOM AND COMPUTING THE MEAN AND STANDARD DEVIATION FOR FOR A REGION OF INTEREST. (ROI) AVERAGE CT NUMBER AVG. CT # AVG. CT NUMBER • WATER – CT# = 0 , +- 3 HU • AIR – CT# = -1,000, +- 5 HU • NOISE +- 10 HU CAUSE OF FAILURE • MISCALIBRATION OF THE CT # GENERATING ALGORITHM FREQUENCY • CT NUMBER OF WATER – DAILY • CT NUMBER OF AIR – MONTHLY CROSS-FIELD UNIFORMITY • THE UNIFORMITY OF CT # THROUGHOUT THE ENTIRE SCAN FIELD OF VIEW IS ONE INDICATION THAT CT SCANNER IS PERFORMANCE IS ACCEPTABLE. • IT REFERS TO THE VALUES OF THE PIXELS IN THE RECONSTRUCTED IMAGE THEY SHOULD BE CONSTANT AT ANY POINT IN THE IMAGE OF PHANTOM UNIFORMITY • NO MORE THAN 2 HU BETWEEN CENTER AND PERIPHERY CAUSE OF FAILURE • NOISE FREQUENCY • DAILY QUALITY MEASUREMENT METHODS OF SPATIAL RESOLUTION • • • • PSF- POINT SPREAD FUNCTION LSF- LINE SPREAD FUNCTION CTF – CONTRAST SPREAD FUNCTION MTF- MODULATION TRANSFER FUNCTION MTF MODULATION TRANSFER FUNCTION MOST COMMONLY USED TO DESCRIBE SPATIAL RESOLUTION IN CT MTF • MTF OF 1 – 100% TRANSFER OF OBJECT TO IMAGE • MTF OF 0 – 0% TRANSFER OF OBJECT TO IMAGE SPATIAL RESOLUTION Lp/cm SPATIAL RESOLUTION • LARGE OBJECTS – LOW S.F. • SMALL OBJECTS – HIGH S.F. SPATIAL RESOLUTION 1 5 ABSOLUTE SIZE OF AN OBJECT IN CT • IT’S EQUAL TO THE RECIPROCAL OF THE SPATIAL FREQUENCY CT SCANNER SPATIAL FREQUENCY- 15 lp/cm. WHAT SIZE OF AN OBJECT CAN THE SCANNER RESOLVE 1/15 = 0.06 mm/lp= 0.6 cm/lp 0.6 /2 = 0.3 mm object Resolution in CT Spatial Resolution Contrast Resolution SPATIAL RESOLUTION • DEGREE OF BLURRING IN THE IMAGE MEASURE OF THE ABILITY TO DISCRIMINATE OBJECTS OF VARYING DENSITY A SMALL DISTANCE APART AGAINST A UNIFORM BACKGROUND HIGH CONTRAST PHANTOM SPATIAL RESOLUTION • 0.45 –0.15 lp/mm (4.5 –15 lp/cm) CAUSE OF FAILURE • EXCESSIVE FSS • MECHANICAL WEAR • DETECTOR VIABRATIONS FREQUENCY • ONCE A MONTH LOW CONTRAST RESOLUTION ( TISSUE RESOLUTION) • THE ABILITY OF AN IMAGING SYSTEM TO DEMONSTRATE SMALL CHANGES IN TISSUE CONTRAST LOW CONTRAST PHANTOM EXPECTED RESULTS • SMALLEST HOLES THAT COULD BE IMAGED SHOULD BE 3 mm IN DIAMETER OR SMALLER FOR 0.5% DENSITYU DIFFERENCE. CAUSE OF FAILURE • NOISE SLICE THICKNESS • IF 5 MM THICKNESS OR MORE IS SELECTED IT SHOULD NOT VARY BY MORE THAN +- 1mm. IF IT IS 5 mm OR LESS IT SHOULD NOT VARY BY MORE THAN +- 0.5 mm. CAUSE OF FAILURE • MISCALIBRATION OF THE COLLIMATION MECHANISM FREQUENCY • SEMIANNUALLY LASER LIGHT ACCURACY • LIGHT AND RADIATION FIELD SHOULD COINCIDE TO 2mm CAUSE OF FAILURE • TUBE MISALIGNMENT • LASER MISALIGNMENT FREQUENCY • ANNUALLY