China tire industry watch

advertisement

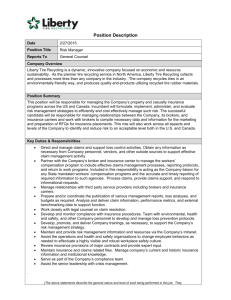

Tire Review’s China Tire Watch [Editor’s Note: Oliver Haiqing Hua, a tire business analyst, has joined the Tire Review team to give periodic insider reports on developments within the Chinese tire industry.] Radial Truck Tire Capacity Expansions According to the recent Chinese "tire industry access conditions" draft issued by the Ministry of Industry and Information Technology (MIIT) of China, future truck radial tire new plant or expansion projects should have production capacity of more than 1.2 million tires annually. By comparison, future radial light truck and car tire new plant or expansion projects should reach an annual output of more than six million tires. Tire demand volume is very large, and with very high safety requirements. Therefore, this draft has put forward a comprehensive planning and requirements for the industry as a whole. So far, there are a large number of tire companies in the market. However, there are very few listing corporations especially in the “A” market; there are only six or seven companies in the Shanghai and Shenzhen A markets that are purely in the tire industry. In the Shanghai A market, there are Double Coin, Aeolus Tyre and Sailun Tyre. In the Shenzhen A market, there are Qingdao Double Star, Guizhou Tyre and Giti Tyre. The draft also encourages the manufacturers to develop the energy-saving, environmental friendly, and safe green tires. Green radial tires are those with new materials and designs that have properties such as low rolling resistance, low fuel consumption, and less exhaust emission. The analysis also believes that the green tire is the future direction of tire industry development. However, there are still very few enterprises that really put green tires into the production. It is understood in China that the development of green tires is the general trend of the world tire industry. It is also a key part in becoming a world rubber industry power. At present, many domestic tire enterprises have entered or announced that they would enter the green tire field. However, without a quantitative standard the flood of the concepts will not be conducive to the healthy development of the industry. Therefore, to issue green tire standard is the urgent requirement of tire industry. The China Rubber Industry Association (CRIA) started research of green tire industry development in 2012. In the shortest possible period of time possible, CRIA completed the "standard" formulation. CRIA is calling on all the tire and raw materials member enterprises to offer proposals, comments or suggestions in the reference of the trial implementation. CRIA will organize the revision accordingly. Nexen Tire Targets Global Top 10 Rank by 2018 Recently, the executives of Nexen Tire Corp. talked about the company’s global strategy during an interview meeting in Shanghai with some business reporters. From the latest global list of top tire manufacturers, Nexen is shown as 23 on the list. The company said it is not satisfied with this result, and is striving to expand their business throughout the world. Nexen Tire was founded in 1942, and claims to be South Korea's first enterprises involving in the production of car tires. Currently, it focuses on the production of car and light truck/SUV tires. Nexen claims an annual growth rate of more than 20% every year, and is targeting to become one of the global top 10 tire manufacturers. Nexen has three plants in South Korea and China, and established six subsidiaries and 11 overseas branches in the U.S., China, and Europe. Through its regional companies and branches, Nexen’s sales business covers more than 130 countries and regions. The tire company has a factory in Qingdao, China, and established sales office in Shanghai. In both the replacement and OE markets, Nexen has set the European, U.S. and China markets as the key areas for expansion. Sales volume and turnover globally has increased year by year; unit volumes have grown from 22.86 million tires in 2010 to 33.55 million tires in 2013. Sales turnover has increased from $760 million in 2008 to $1.67 billion in 2013. It is expected in 2014, Nexen global sales will exceed 36 million tires. Currently, Nexen’s total global production capacity has reached 35 million tires, of which the Qingdao factory has a capacity of 10 million tires; Liangshan, South Korea, factory has a capacity of 19 million, and new Changnyeong-gun, South Korea, factory 6 million. With the planned Changnyeong capacity expansion in 2015, Nexen total global production capacity will reach 43 million tires. China Tiremakers See Greater Role in U.S. Market Not long ago, the Double Coin general manager Zhang Wanyou visited the U.S. According to Zhang, he has met more Chinese tire enterprises in the U.S. than he met in China. He feels that all Chinese tire enterprises are trying all means necessary to exploit the international market. During the China Rubber Industry Association (CRIA) Tyre Branch general assembly, he shared his experience with the participants. It is understood that about half of the tires produce in China are for export. However, Chinese tire enterprises are unwilling to lag behind; they all have accelerated the pace of globalization and strengthened their development of an international market. Zhang mentioned that other domestic tire enterprises also have the same feeling. A manger from Shandong Tyre Co. told reporters that in recent years, at the famous annual SEMA Show tire exhibition they have attended, they always seen more foreign faces than the year before. In recent years, there are more and more Chinese at the SEMA Show. He said that it is not exaggerating that the trade show has almost become a Chinese tire professional exhibition. Data shows that in 2012, the Chinese tire export growth rate reached 9.6% year-on-year. By 2013, the tire export volume growth rate reached 13.3%. Because of excessive domestic low-end production capacity, market competition has become intensified so that the domestic tire enterprises have chosen to increase their export efforts. Vice president and secretary general of CAAM Xu Wenying said, in 2013, the U.S. had imported a total volume of 43.57 million passenger car tires from China, accounting for about 32% of the U.S.’s total passenger car tire imports. "This shows that for every three imported passenger tires in America, there is one from the China." At the same time, the Chinese tire export volume to the U.S. has also grown by 24%. Although this has brought about the prosperity and development of Chinese tire export market, it is growing too fast and easily influenced a related trade policy enacted in 2009. That trade “safeguard" policy was one of the important trade barriers the U.S. government took on imported Chinese tires, and another tariff may be coming. It worth mentioning that Chinese industrial experts have called upon the tire enterprises to not ignore technical innovation in order to fulfill their export orders. They believe Chinese tire enterprises need to continue improving tire technology and their R&D efforts to improve the technological content of their products and, therefore, improve their value in the current market. This can also, they suggested, reduce the risk of destination countries creating trade barriers. With New Plant, Linglong Tyre Building an Internationalized Tire Enterprise Recently, Linglong Tyre International (Thailand) Co.’s first-phase tire plant project started full production. The first phase of this project has an annual production capacity of two million units of high performance tires. Nearly 500 partners – distributors and retailers – from more than 180 countries and regions around the world visited the factory in Thailand tp witness the tire production launch ceremony. During the ceremony, the partners heard that Linglong Tyre’s internationalization strategy has stepped into the fast lane, and started a new era as a world-class tire enterprise. Thailand is Linglong Tyre's first overseas production base, is the starting point in the company’s strategy to build three domestic manufacturing facilities and three overseas manufacturing bases. The Linglong Tyre Thailand factory project has a total investment of nearly $700 million, with an overall annual scale of 13.2 million tires. The project features high-level production equipment. The entire production line is fully equipped with a first-class calendar, cutting machine, one shot forming machine, hydraulic machine and other high-end production equipment. The result is high precision, good stability, and high degree of automation. Reportedly, products from the new Thailand plant are already in short supply. Plans for the second phase of the project have been submitted to China National Development and Reform Commission for the required recording. The company will take three to four years to complete the construction and put it into production. China Tire Industry Analysis for April and May At the time, there was stable work force during the winter in China so the labor cost element on tires will be reduced. In the winter of 2012, many of the tire production enterprises were operating at full productive capacity. This caused the tire inventory surged for each of the tire manufacturers. In some individual tire factories, the inventory once exceeded over 400,000 units at a value of more than $165 million. Despite previous experiences, each tire production enterprise made wrong predictions on the tire market in 2013. One year later, the majority of domestic projects in China remain in the planning stage, not many of them have been implemented so the market remains in the doldrums. As a result, many of the tire manufacturers are facing economic crisis last year. The essence of the crisis is the imbalance of tire supply and demand, overcapacity and lack of consumption. Tires have been produced that cannot be sold quickly at a desired price, causing cash flow issues that have led to business failures and production decline. In order to withdraw the circulation funds and avoid a collapse, tire enterprises have started a brutal price war. "Entangling" and "helpless" are again the two words that best described the Chinese tire market in March 2014. The continuous downward trend has resulted in much depression to the market atmosphere. Most tire sellers had a "vulnerable" feeling about the tire business they depend on, and wondered if April would turn the page. The following is the summarization of the risk factors that affect the tire market in April and May 2014 in China: • In March, the natural rubber price continues to jigger around like the roller coaster. Take Yunnan state-owned latex as an example, the highest point of March was 15,200 yuan (US$2,533.33)/ton, while the lowest was 14,050 yuan (US$2,341.67)/ton, and the average price was calculated as 14,658 yuan (US$2,443.00)/ton, compared with the average price of 15,416 yuan (US$2,402.67)/ton one month prior, the price has dropped down by a rate of 5%. • In view of the then current rubber price market, the majority of tire manufacturers did not have plans to increase the inventory of raw materials. The rubber price could continue fluctuating in the short term, and the tire manufacturers will still be purchasing based on real-time demand. If rubber prices continue to be running at a weak vulnerable level, the tire prices will hardly keep stable. "Watch the rubber price, and gamble on the tire market" has become the unwritten rule as it pertains to current tire prices. The tire market in January and February was as tepid as a cup of bad tasting coffee, and it would be easy to explain by the Chinese New Year season production slow down. But in March the tire market continued downward and there was no resistant measures are taken. The manufacturers no longer give customers any buffer time; dealers have to purchase "according to the agreement plan.” To complete their quarterly requirements, dealers purchased more tires in March than the total tires they purchased during the previous two months. No wonder the market feedback was so bad – but where were the tires in the manufacturers’ inventories? The answer was simple: manufacturers moved like a raging fire to get those tires from their warehouse to avoid their own risk. Before the true digestion of the "transferred tires” in the market, its deterrent force cannot be ignored. "The inventory has been depreciated that caused the money lost. It is not the time for high stakes." This has become the current attitude on the market among dealers. After the Chinese New Year holidays, most of the businesses were working through their inventory with some replenishment of best-selling models. Due to the lack of confidence, the regular large quantities of tire purchasing were not carried out. The April and May factors are still the mainstream, and short-term tire price will continue to drop down. Unless the infrastructure has been driven significantly to bring in the rigid demand, all other factors will not do much to push up the market. Linglong Tyre Performed Performance Testing in the U.S. On March 15-16, the Linglong Tyre research staff performed performance testing on Linglong Tyre Cross Wind M/T tire in the U.S. The testing included tire subjective noise, handling, dry/wetland control and braking. The manufacturer said that test results showed that in the aspects of noise control, comfort, anti-skidding performance and regular control, the Linglong Cross Wind M/T was superior to the other brand tires participating in the tire test. This is the first time Linglong Tyre performed tire testing in North America. Sailun Tyre Raises $600 Million for Tire Production Project On April 9, Sailun Tyre announced that it intends to issue the non-public offering at a share price of not less than 12.17 yuan (US$2.03) per share for not more than 98.6 million shares. The offering would raise approximately 1.2 million yuan (US$600 million), some of which is to be applied to increase production to an annual output of 15 million high performance steel radial tires by the company’s wholly owned subsidiary – Jinyu Industries. Once the project has achieved up to normal production, the annual income revenue will reach 3.701 billion yuan (US$616.68 million), with the net profit of up to 248 million yuan (US$41.67 million). The project investment profit rate is 15.02%. After the increase of 15 million tires, Sailun Tyre’s tire production capacity will reach 44.8 million tires (including Sailun Tyre Vietnam’s 7.8 million tires production capacity) – all within three years time. Sailun Tyre has performed a classic play of using the capital market and quickly become a bigger and stronger tire manufacturing company. In August 2012, Sailun Tyre had only been listed a little bit more than a year; it spent 170 million yuan (US$28.33 million) to buy 49% of Shandong Jinyu Tire. At the same time, it acquired 100% ownership of Shenyang Peace Tyre at a price of 120 million yuan (US$20 million). In June 2013, Sailun Tyre acquired the remaining 51% stake in Shandong Jinyu Tyre with a non-public offering fund raising of a total of 220 million yuan (US$36.67 million). Sailun Tyre net profit has been grown from 100 million yuan (US$16.67 million) in 2011 to 160 million yuan (US$26.67 million) in 2012 and further up to 244 million yuan (US$46.67 million) in 2013. China Builds Rolling Resistance Comparison Test Lab After a recent working meeting in Beijing, during which seven labs in the country were considered, China National Tyre Quality Supervision and Inspection Center (CNTQSIC) was selected as the only third party testing institution to be awarded the certificate for the car, light truck, and truck tires rolling resistance comparison testing. The group found that tire rolling resistance test machines give very different test results base on each individual test machine’s own characteristics. Therefore, those results cannot provide the base data for tire rolling resistance evaluation. To resolve this problem, the European Union adopted a method of establishing the basic standard, averaging the value from rolling resistance tests conducted at nine labs to serve as the base standard value. China Metrology Association borrowed the EU method, establishing a tire rolling resistance reference laboratory network, and issued the certificates and plaques to the first batch of laboratories. The CNTQSIC was shown to have the best tire rolling resistance test method and data evaluation system. It can provide test data in accordance with the requirements of EU value limit and meet labeling regulations and legislation. It also can provide test results in accordance with the Chinese national standard method. Anhui HeDing Tires Project Put into Operation in May Anhui HeDing Tires Technology Co. Ltd.’s new plant project is located in Anhui Huaiyuan Economic Development Zone with a total investment of 2 billion Yuan (US$334 million). Anhui HeDing Tyres is mainly engaged in the manufacturing and sales of the high performance, environment and energy saving radial tires. The project covers an area of 666,667 square meters with a total under-roof area of 210,000 square meters. The project will be constructed in two phases. The first phase of 170,000 square meters space will be put into operation in May 2014. Anhui HeDing Tyres was founded in April 2011, and focuses on new technology and new product development. It has enhanced brand innovation ability and strives to be close to the market and maximize services to satisfy customer demand. HeDing Tyres’ products have been positioned for the high-end market for the domestic and foreign enterprises. In the Chinese domestic market, Anhui HeDing Tyres distributes its products mainly through a sales agent network. Guangrao: A Place Where Tires Meet In Guangrao, China, there are over 42 above-scale tire enterprises and nearly 100 smaller tire enterprises. The radial tire production capacity in Guangrao County has reached 150 million tires, accounting for one-fourth of the national total. The tire industry in Guangrao has achieved exports amounted to US$2.94 billion in 2013 alone. Even though there is no one as famous as Linglong Tyres, Double Star Tyres or Aeolus Tyres and other well-known domestic brands, or any international giant such as Michelin and Bridgestone, what makes Guangrao stand out in the tire industry in China as well as in the world? Founded in 2009, Shandong Haoyu may better understand the role that quality has played in the development of the enterprises. Company chairman Zhu Yuncheng has been engaged in rubber industry for more than 30 years. He has experienced the rise of Guangrao tire industry, and witnessed the development of Guangrao tire. He said that production overcapacity and fierce price competition are the pains in the neck that the Guangrao tire industry can live without. Only a quality tire can make the enterprises stronger and bigger, Zhu concluded from his experience. Shandong Haoyu has given identity to each tire it produces so that each tire can be traced back and the company can control the quality in detail. Zhu said there is a unique code for each tire at each link of the production processes. Any quality defect can be traced back to the link and the person in charge so that each of the production staff will maintain a high quality consciousness. At the same time, Shandong Haoyu has adopted a tire process technology that has been used in the international production. This method can avoid the unavoidable defects due to human interference during the building and curing processes, which cause production instability and quality uncontrollability. In the production final test stage of production, all Shandong Haoyu tire products pass through X-ray machines. Destructive testing also needs to be performed on certain tires from each batch before the product put into the market. A set of highly standardized requirements guard each of the quality procedures. Guangrao county government also requires the Guangrao tire to consider quality as a business card. China General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) set up the "national rubber tire product and material quality supervision and inspection center" in Guangrao. Guangrao County government has provided the land and 45 million yuan to build a 20,000-square-meter testing laboratory. Coungty quality inspection bureau chief Yang Zhenguo revealed that Guangrao County will work with AQSIQ to invest 1 billion yuan (US$166.67 million) in the construction of a tire test facility that covers one million square meters. Yang said that the tire testing facility will test all the tire products in order to improve product quality and technology and better adapt to the market needs. China’s tire industry has no national test facility, so tires can only be tested by sending them to foreign countries. The construction of this tire testing facility in Guangrao County will solve this problem. Yang stressed that this fundamental change in traditional business can lead the progress of China national tire industry and enhance the international competiveness of the tire enterprises.