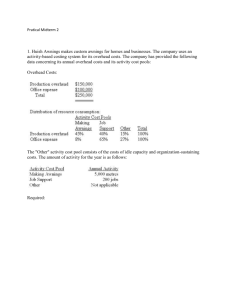

Costing Systems

advertisement

Costing Systems EMBA 5403 Fall 2010 Available costing systems Absorption costing Actual Costing Normal Costing Standard Costing Variable costing Actual Costing Normal Costing Standard Costing Fall 2010 Mugan 2/37 Costing systems Cost component Actual Normal Standard material Actual Actual Standard labor cost Actual Actual Standard Manufacturing OverheadVariable Actual Applied Standard Manufacturing Overhead-Fixed Actual Applied Standard Applied Fall 2010 Mugan 3/37 Variance Differences between the costs according to the costing system used and actual amounts Actual amounts are reflected in the financial statements Fall 2010 Mugan 4/37 Absorption Costing Cost of Goods Manufactured Absorption costing allocates variable and fixed overhead costs to products. Cost of Goods Sold Fall 2010 Mugan Finished Goods Inventory Valuation 5/37 Product Costing Procedures in Organizations Process Costing Job-order Costing Distinct jobs or batches of units. • Costs accumulated separately by job. •Typical job order cost applications: • Special-order printing • Building construction • Also used in service industry • Hospitals Fall 2010 Mugan • Law firms 6/37 Product Costing Procedures in Organizations Process Costing Job-order Costing Typical process cost applications: Fall 2010 Petrochemical refinery Paint manufacturer Paper mill Mugan 7/37 Job-Order Costing Manufacturing overhead (MOVH) Applied (added) to each job using a predetermined rate Direct materials The Job Direct labor Fall 2010 Mugan 8/37 Job-Order Costing Direct material s and labor Raw materials could be used as direct or indirect product cost. Part of the job cost Materials Requisition and Time tickets An employee’s time may be either direct or indirect. Fall 2010 Indirect materials and labor Mugan Manufacturing Overhead Control Account 9/37 Job-Order Costing wages Other Actual OH Charges Material usage Fall 2010 Indirect Labor Manufacturing Applied Overhead Overhead Control Account Job-Order Cost Sheets Indirect Materials Mugan 10/37 Job-Order Cost Sheet XYZ Job-Order Cost Sheet Job Number A - 143 Department A4 Item Steel water tank Date Initiated 17 September 2008 Date Completed 17-Nov-08 Units Completed 2 Direct Materials Direct Labor Manufacturing Overhead Req. No. Amount Ticket Hours Amount Hours Rate Amount MR 1041 TL 1200 20 8 TL 160 8 TL 6 TL 48 Cost Summary Direct Materials Direct Labor Manufacturing Overhead Total Cost Unit Cost Fall 2010 Units Shipped Date Number Balance TL 1200 TL 160 TL 48 1408 Mugan 704 11/17/08 1 1 11/37 Job-Order System Cost Flows Salaries and Wages Payable Direct Labor Indirect Labor Mfg. Overhead Actual Applied Indirect Overhead Materials Applied to Indirect Work in Mugan Fall 2010 Labor Process Work-in-Process (Job Cost Sheet) Direct Materials Direct Labor Overhead Applied If actual and applied manufacturing overhead are not equal, a year-end adjustment is required. 12/37 Job-Order System Cost Flows Work-in-Process (Job Cost Sheet) Direct Materials Direct Labor Overhead Applied Cost of Goods Mfd. Finished Goods Cost of Goods Mfd. Cost of Goods Sold Cost of Goods Sold Cost of Goods Sold Mugan Fall 2010 13/37 Allocation Process Define the cost objects. Accumulate indirect costs in cost pools. Choose an allocation base. Estimate an application rate. Allocate indirect costs based on use of the allocation base Fall 2010 Mugan 14/37 Over- and Underabsorbed Overhead Overabsorbed overhead Applied Overhead Costs > Actual Overhead Costs Underabsorbed overhead Applied Overhead Costs Fall 2010 < Mugan Actual Overhead Costs 15/37 Over- and Underabsorbed Overhead XYZ’s actual overhead for the year was TL650,000 and a total of 100,000 direct labor hours were worked. Using XYZ’s predetermined overhead rate of TL 6.00 per direct labor hour, how much overhead was applied to XYZ’s jobs during the year? SOLUTION Applied Overhead = POHR × Actual Direct Labor Hours Applied Overhead = TL 6.00 per DLH × 100,000 DLH = TL 600,000 Fall 2010 Mugan 16/37 Accounting for Over- and Underabsorbed Overhead Three basic approaches Prorate among work-in-process, finished goods, and cost of goods sold. Adjust cost of goods sold. Recalculate the application rate and apply to all the jobs during the period. Fall 2010 Mugan 17/37 Accounting for Over- and Underabsorbed Overhead If Manufacturing Overhead is . . . UNDERABSORBED Alternative 1 Close to Cost of Goods Sold Alternative 2 INCREASE Cost of Goods Sold INCREASE Work-in-Process Finished Goods Cost of Goods Sold DECREASE Cost of Goods Sold DECREASE Work-in-Process Finished Goods Cost of Goods Sold (Applied OH is less than actual OH) OVERABSORBED (Applied OH is greater than actual OH) Fall 2010 Mugan Allocation 18/37 Allocation Base If overhead costs are accumulated in a single cost pool and allocated using a single allocation base. Single Overhead Cost Pool Application Rate Products Fall 2010 Mugan 19/37 Multiple Allocation Bases Many companies use Activity Based Costing where multiple cost pools and a different allocation base for each cost pool. Overhead Cost Pool A Application Rate A Fall 2010 Overhead Cost Pool B Overhead Cost Pool C Application Rate B Products Mugan Application Rate C 20/37 ABC and Multiple Allocation Bases Improves planning and control. Activity Based Costing (ABC) is one method of using multiple allocation bases. Fall 2010 Mugan 21/37 Multistage Allocation Processes Overhead Cost Pool 1 Overhead Cost Pool 2 Overhead Cost Pool 3 Overhead Cost Pool 4 Separate Application Rates Department A Department B Dept. Application Rates Fall 2010 Department C Dept. Application Rates Products Mugan 22/37 Process Costing Identical units of product are produced in a continuous flow through a series of manufacturing steps or processes. Costs are assigned to completed units transferred out of the process and to incomplete units remaining in the process. Fall 2010 Mugan 23/37 Process Costing Costs are accumulated for a period of time for products in work-in-process inventory. Equivalent units is a concept expressing these partially completed products as a smaller number of fully completed products. Fall 2010 Mugan 24/37 Equivalent Units Two one-half completed products are equivalent to one completed product. = + So, 8,000 units 70 percent complete are equivalent to 5,600 complete units. Fall 2010 Mugan 25/37 Equivalent Units Question For the current period, Ames started 15,000 units and completed 10,000 units, leaving 5,000 units in process 30 percent complete. How many equivalent units of production did Ames have for the period? a. 10,000 b. 11,500 c. 13,500 d. 15,000 Fall 2010 Mugan 26/37 Equivalent Units Question For the current period, Ames started 15,000 units and completed 10,000 units, leaving 5,000 units in process 30 percent complete. How many equivalent units of production did Ames have for the period? a. 10,000 10,000 units + (5,000 units × .30) b. 11,500 = 11,500 equivalent units c. 13,500 d. 15,000 Fall 2010 Mugan 27/37 Calculating and Using Equivalent Units of Production To calculate the cost per equivalent unit for the period: Cost per equivalent unit Fall 2010 = Costs for the period Equivalent units for the period Mugan 28/37 Equivalent Units Question Now assume that Ames incurred $27,600 in production costs for the 11,500 equivalent units. What was Ames’ average cost per equivalent unit for the period? a. $1.84 b. $2.40 c. $2.76 d. $2.90 Fall 2010 Mugan 29/37 Equivalent Units Question Now assume that Ames incurred $27,600 in production costs for the 11,500 equivalent units. What was Ames’ average cost per equivalent unit for the period? a. $1.84 $27,600 ÷ 11,500 equivalent units b. $2.40 = $2.40 per equivalent unit c. $2.76 d. $2.90 Fall 2010 Mugan 30/37 Equivalent Units Question What portion of the $27,600 in production costs was assigned to work-in-process inventory and what amount was assigned to completed units for the period? a. $0 and $27,600 b. $7,600 and $20,000 c. $3,600 and $24,000 d. $12,000 and $15,600 Fall 2010 Mugan 31/37 Equivalent Units Question Work-in-process: What portion of the $27,600 in production 1,500 equivalent units @ $2.40 = $3,600 costs was assigned to work-in-process inventory and what amount was assigned Completed units: 10,000 equivalent $2.40 = $24,000 to completed units forunits the @ period? a. $0 and $27,600 b. $7,600 and $20,000 c. $3,600 and $24,000 d. $12,000 and $15,600 Fall 2010 Mugan 32/37 Equivalent Units When there are partially completed units in beginning inventory, work efforts during the period can be categorized as follows: Work to complete beginning work-in-process Work on units started and completed during the period Work on units in ending work-in-process Fall 2010 Mugan 33/37 Equivalent Units - Example ACE started June with 250 partially completed units in work-in-process (30% complete). During June, ACE completed the units in workin-process and started an additional 1,200 units. There were 300 units in ending work-in-process on June 30. They were 40% complete. How many total equivalent units did ACE produce during June? Continue Fall 2010 Mugan 34/37 Equivalent Units - Example units % of work done this period Equivalent units Work to complete 250 70% beginning work-in-process Work on units started and 900 100% completed Work on ending work-inSince 30% of the work 300 was done 40% on processthese units in May, the remaining 70% of Total equivalent units the work is done in June. Fall 2010 Mugan 175 900 120 1,195 35/37 Equivalent Units - Example units % of work done this period Equivalent units Work to complete 250 70% 175 beginning work-in-process Work on units started and 900 100% 900 completed Work on ending work-in300 40% 120 process Since 1,200 units were started during June, and 300 of Total equivalent units 1,195 those units are still in work-in-process on June 30, 900 units were started and completed during June. Fall 2010 Mugan 36/37 Equivalent Units - Example Work to complete beginning work-in-process Work on units started and completed Work on ending work-inprocess Total equivalent units units % of work done this period 250 70% 175 900 100% 900 300 40% 120 Equivalent units 1,195 40% of the work was done on these units in June. Mugan 37/37 Fall 2010