16b Masonry - Code-Overview MCG 2015

advertisement

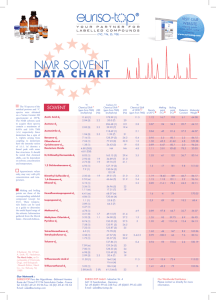

Overview of Masonry Codes W. Mark McGinley , Ph. D. PE University of Louisville (from TMS seminars and R. Bennett) 1 The Masonry Society – Who we are TMS is a not-for-profit professional society, whose mission is simply to advance the knowledge of masonry TMS is the lead sponsor of the Masonry Standards Joint Committee, who is responsible for the “MSJC” standards (TMS 402/TMS 602) For more information, visit us at: www.masonrysociety.org Slide 2 Masonry Codes and Standards Almost the entire US now uses the IBC. We will focus on the 2015 IBC. The IBC extensively references “Consensus” Design and Material Standards: ASTM Standards for Materials ASCE 7 for Loads ACI 318 for Concrete “MSJC” (TMS 402/602) for Masonry 3 IBC Masonry Requirements Chapter 7 – Fire Ratings Chapter 14 – Veneer Chapter 17 – Quality Assurance Chapter 18 – Foundation Walls (includes prescriptive requirements based on TMS 402 Strength Design Procedures) Chapter 21 – Masonry 4 IBC Masonry Requirements In the past, some of the TMS 402/602 provisions were duplicated in the IBC. Differences between the TMS 402/602 and the IBC were hard to spot. Same was true of ASTM Standards. Most of these duplicate provisions were removed from the 2009 IBC, making differences much easier to spot. More duplicate provisions were deleted from the 2012 and additional duplications were removed in the 2015 IBC 5 IBC Special Inspection The Special Inspection requirements in Chapter 17 of the 2015 (and the 2012) IBC are quite different in appearance than those in earlier editions of the IBC, but in substance, the requirements are nearly identical. In essence, the 2009 and earlier IBC’s based their provisions on the TMS 402/602 and tweaked them in tables. Now, the 2012 & 2015 IBC simply references the TMS 402/602 6 IBC Chapter 21 Section 2101 General Section 2102 Definitions and Notations Section 2103 Masonry Construction Materials Section 2104 Construction Section 2105 Quality Assurance Section 2106 Seismic Design Section 2107 Allowable Stress Design Section 2108 Strength Design of Masonry Section 2109 Empirical Design of Masonry Section 2110 Glass Unit Masonry Section 2111 Masonry Fireplaces Section 2112 Masonry Heaters Section 2113 Masonry Chimneys 7 IBC Section 2107: ASD IBC Section 2107 requires compliance with TMS 402 Chapter 8, except for: Modifies splice & development lengths. Allows a simpler procedure, and in some cases is more conservative and in some cases less conservative than the TMS 402 Has additional requirements for mechanical and welded splices ASTM A706 steel required for welded lap splices. ACI 318 Type 1 or 2 mechanical splices required. Limits the maximum bar size to No. 9. 8 IBC Section 2107: ASD Lap Splice Detailing Requirements for allowable stress design: ld = 0.002 db Fs ld = 64 db (for Grade 60 reinforcement) Increase lap length by 50% when the computed stress in reinforcement is 80 % or more of the allowable stress in reinforcement (Fs). 9 IBC Section 2108: SD IBC Section 2108 requires compliance with TMS 402 Chapter 9, except: Splice and development lengths capped at 72 db for No. 7 and larger bars, the 72 db cap governs, and the IBC gives a shorter splice length than the TMS 402. Has additional requirements for mechanical and welded splices ASTM A706 steel required for welded lap splices. ACI 318 Type 1 or 2 mechanical splices required. 10 Last Thoughts: I - Codes The IBC references standards such as the TMS 402/602 and ASCE 7. The IBC cannot be used without those other standards. The 2006 IBC made some modifications to the TMS 402/602. The 2009 IBC made no major modifications to the 2008 TMS 402/602. And it removed redundant transcribed text, so that modifications are now much easier to find. 2012 and 2015 IBC’s rely on TMS 402/602 even more. 11 TMS 402/602 TMS 402 “Code” Design provisions are given in Chapters 1 - 14 and Appendices A, B and C Sections 1.2.4 and Chapter 3 require a QA program in accordance with the Specification Section 1.4 invokes the Specification by reference. TMS 602 “Specification” verify compliance with specified fm comply with required level of quality assurance comply with specified products and execution 12 TMS 402/602 1988: First edition 1995: Seismic requirements moved from Appendix to main body of code; chapter on veneers added; chapter on glass block added 1998: Major reorganization of code; prestressed masonry chapter added 2002: Strength design chapter added; definitions of shear walls added to correspond to IBC definitions; code moved to a three year revision cycle 2005: Changed lap splice requirements, requiring much longer lap lengths 2008: Major reorganization of seismic requirements; added AAC masonry in Appendix 2011: Eliminated one-third stress increase and recalibrated allowable stresses; added infill provisions in Appendix 2013: Changes for partially grouted shear walls; updated unit strength table; limit states appendix 13 Why a 2 Year Cycle From 2011 to 2013? ICC rule changes forced Standards Developers to modify their revision cycle to allow additional time to review standards before incorporation into the IBC. To react to these changes, the 2013 TMS 402/602 was developed in a shortened cycle to allow adoption by the 2015 IBC. The end results: The 2013 TMS 402/602 has been adopted by the 2015 IBC/IRC The next edition is targeted for 2016 to get back on the 3-year revision cycle 14 Why the Name Change to TMS 402/602 In the past, the “MSJC” was developed by TMS, ACI and ASCE. Good arrangement, but multiple names confused some, and many wanted to see the document reflect the work of TMS, the lead sponsor In late 2013, ACI and ASCE relinquished their rights to future editions so that it will now be called the TMS 402/602, much like ACI 318 identifies the concrete code. To start re-education, we’ll use TMS 402/602 when referring to the 2013 edition, and the MSJC when referring to the Committee or earlier editions 15 2011 TMS 402 MSJC TMS 602 Ch. 1 - General Requirements Ch. 2 Allowable Stress Design Ch. 3 Strength Design Ch. 4 Prestressed Masonry 3.1 - General SD 3.2 - URM 3.3 - RM 2.1 - General ASD 2.2 - URM 2.3 - RM Ch. 5 Empirical Design Ch. 6 Veneer Ch. 7 Glass Block 6.1 - General 6.2 - Anchored 6.3 - Adhered 2011 TMS 402 also included a new Appendix for Design of Masonry Infill 16 Ch. 8 AAC 2013 TMS 402 (Reorganized) Part 1: General Part 2: Design Requirements Part 3: Engineered Design Methods Part 4: Prescriptive Design Methods Part 5: Appendices & References Chapter 1 – General Requirements Chapter 4: General Analysis & Design Considerations Chapter 8: ASD Chapter 12: Veneer Appendix A – Empirical Design of Masonry Chapter 2 – Notations & Definitions Chapter 5: Structural Elements Chapter 9: SD Chapter 13: Glass Unit Masonry Appendix B: Design of Masonry infill Chapter 3 – Quality & Construction Chapter 6: Reinforcement, Metal Accessories & Anchor Bolts Chapter 10: Prestressed Chapter 14: Masonry Partition Walls Appendix C: Limit Design of Masonry Chapter 7: Seismic Design Requirements Chapter 11: AAC References 17 2013 TMS 602 TMS 402 Code TMS 602 Specification Part 1 General Part 2 Products Part 3 Execution 1.6 Quality assurance 2.1 - Mortar 2.2 - Grout 2.3 – Masonry Units 2.4 – Reinforcement 2.5 – Accessories 2.6 – Mixing 2.7 - Fabrication 3.1 - Inspection 3.2 - Preparation 3.3 – Masonry erection 3.4 – Reinforcement 3.5 – Grout placement 3.6 – Prestressing 3.7 – Field quality control 3.8 - Cleaning 18 TMS 402 Part 1 General Requirements Ch. 1: Scope, Contract documents and calculations, Special Systems, Reference Standards Ch. 2: Notation, Definitions Ch. 3 Quality & Construction Requires a quality assurance program in accordance with the Specification three levels of quality assurance (A, B, C) increasing levels of quality assurance require increasingly strict requirements for inspection, and for compliance with specified products and execution 19 TMS 402 (& IBC) QA Requirements Required Tests and Submittals Masonry material certificates ′ Verify 𝑓𝑚′ & 𝑓𝐴𝐴𝐶 prior to construction** Level A* Level B Level C • • • • • ′ Verify 𝑓𝑚′ & 𝑓𝐴𝐴𝐶 every 5,000 sq. ft. during construction** • Verify proportions of materials in premixed or preblended mortar & grout • Verify slump flow & VSI of SCG *Exempt from IBC • • Periodic Continuous ** For Engineered masonry and not for Veneer, Glass United Masonry or Empirically Designed Masonry 20 TMS 402 (& IBC) QA Requirements Minimum Special Inspection for Traditional Masonry* Verify compliance with approved submittals Level A Level B Level C PT PT PT Verify proportions of site-prepared mortars Construction of mortar joints Placement of masonry units Location of reinforcing, connectors and anchorages - PT PT PT PT PT PT FT Grout space (prior to grouting) Grade, type, and size of reinforcing, anchor bolts & anchorages - PT PT FT FT - PT PT FT FT - PT PT PT FT FT FT Verify proportions of site-prepared grout Size, type & location of attachments to other structural elements Size and location of structural elements Observe preparation of prisms and grout or mortar specimens Grout Placement * Does not include Prestressed masonry, Hot & Cold Weather requirements, etc. Refer to MSJC for specific Requirements •PT – Part Time or Periodic FT – Full Time or Continuous 21 Restricts pour height based on width/space minus horizontal reinforcement which restricts the space Grout Pour Grout space requirements in Table 3.2.1 are intended to provide adequate room for placement of grout. Grout Lift Grout Lift TMS 402 Section 3.2: Construction 22 TMS 402 Part 2: Design Requirements Ch. 4: General Analysis & Design Considerations 4.1 Loading 4.2 Material properties 4.3 Section properties 4.4 Connections to structural frames 4.5 Masonry not laid in running bond Ch. 6: Details of reinforcement, metal accessories & anchor bolts Ch. 7 Seismic design requirements Ch. 5: Structural Elements 23 Masonry Building System Walls parallel to lateral forces act as shear walls to resist in-plane loads; they may resist axial loads Bond beams transfer reactions from walls to horizontal diaphragms (floors and roof), and act as diaphragm chords Walls perpendicular to lateral forces resist moments from out-of-plane loads and transfer reactions to horizontal diaphragms; they may resist axial loads 24 TMS 402 Section 4.3: Section Properties Use minimum (critical) net area for computing member stresses or capacities. Radius of gyration and member slenderness are better represented by the average section 25 TMS 402 Part 2: Design Requirements Ch. 4: General Analysis & Design Considerations Ch. 5: Structural Elements 5.1 Masonry assemblies 5,2 Beams 5.3 Columns 5.4 Pilasters 5.5 Corbels Ch. 6: Details of reinforcement, metal accessories & anchor bolts Ch. 7 Seismic design requirements 26 TMS 402 5.1.1: Wall Intersections nominal flange thickness, t 50% interlocking units L = 6 t for compression or unreinforced masonry in tension L = 3/4 floor - to - floor wall effective flange height for reinforced length, L masonry in tension wall to the right of movement joint not part of flange of web wall movement joint 27 TMS 402 5.1.2: Effective Comp. Width For running - bond masonry, or masonry with bond beams spaced no more than 48 in. center – to – center, the width of compression area per bar for stress calculations shall not exceed the least of: Center - to - center bar spacing Six times the wall thickness (nominal) 72 in. 28 TMS 402 5.1.3: Concentrated Load Dist. The critical area for walls laid in running bond shall not exceed the wall thickness times the smaller of: Length of bearing area plus a length determined by a dispersion of 2 vertical: 1 horizontal. That dispersion is limited by the smallest of one - half the wall height, a movement joint, the end of the wall, or an opening. Center – to – center distance between concentrated loads 29 TMS 402 5.1.3: Concentrated Load Dist. Load Load Load 1 2 h 2 h/2 1 Effective Length Effective Effective Length Length 30 TMS 402 5.2: Beams Span length equals clear span plus depth, but not more than distance between support centers Moments for continuous beams based on center to - center spans Minimum bearing distance = 4 in. Lateral support on compression face required at a maximum spacing of 32 times the beam thickness (nominal) but no more than 120b2/d Must meet deflection limits of TMS 402 Section 5.2.1.4 31 TMS 402 5.3: Columns Columns are defined in TMS 402 Section 5.3 ISOLATED member that primarily resists compressive loads h / r 99 Minimum side dimension: 8 in. Minimum design eccentricity = 0.1 x t 0.25% g 4.0% At least 4 longitudinal bars, laterally tied, except for lightly loaded columns 32 TMS 402 Part 2: Design Requirements Ch. 4: General Analysis & Design Considerations Ch. 5: Structural Elements Ch. 6: Details of reinforcement, metal accessories & anchor bolts Ch. 7 Seismic design requirements 33 TMS 402 6.1: Reinforcement reinforcing bars must be embedded in grout; joint reinforcement can be embedded in mortar placement of reinforcement protection for reinforcement standard hooks 34 TMS 402 6.2: Anchor Bolts Tensile capacity governed by tensile breakout tensile pullout yield of anchor in tension Shear capacity governed by shear breakout masonry crushing shear pryout yield of anchor in shear For combined tension and shear, use linear interaction Headed bolts, J bolts or L - bolts Must be embedded in grout 35 TMS 402 Part 2: Design Requirements Ch. 4: General Analysis & Design Considerations Ch. 5: Structural Elements Ch. 6: Details of reinforcement, metal accessories & anchor bolts Ch. 7 Seismic design requirements 36 Shear Walls: Minimum Reinforcement SW Type Minimum Reinforcement SDC Empirically Designed none A Ordinary Plain none A, B Detailed Plain Vertical reinforcement = 0.2 in.2 at corners, within 16 in. of openings, within 8 in. of movement joints, maximum spacing 10 ft; horizontal reinforcement W1.7 @ 16 in. or #4 in bond beams @ 10 ft A, B Ordinary Reinforced same as above A, B, C Intermediate Reinforced same as above, but vertical reinforcement @ 4 ft A, B, C Special Reinforced same as above, but horizontal reinforcement @ 4 ft, and = 0.002 any 37 TMS 402: Chapter 7 Seismic Design Category A drift limit of 0.007 from ASCE 7 - 10 (Section 12.12.1) for typical masonry structures minimum design connection force for wall - to roof and wall - to - floor connections from ASCE 7 - 10 (Section 12.11.2) Seismic Design Category B lateral force – resisting system cannot be designed empirically 38 TMS 402: Chapter 7 Seismic Design Category C Shear walls must meet minimum prescriptive requirements for reinforcement and connections (ordinary reinforced, intermediate reinforced, or special reinforced) Other walls must meet minimum prescriptive requirements for horizontal or vertical reinforcement 39 TMS 402: SDC C Ordinary Walls roof connectors @ 48 in. max oc roof diaphragm #4 bar (min) within 16 in. of top of parapet Top of Parapet #4 bars around openings #4 bar (min) within 8 in. of corners & ends of walls 24 in. or 40 db past opening #4 bar (min) @ diaphragms continuous through control joint #4 bar (min) within 8 in. of all control joints control joint #4 bars @ 10 ft oc #4 bars @ 10 ft oc or W1.7 joint reinforcement @ 16 in. oc 40 TMS 402: Chapter 7 Seismic Design Category D Masonry that is part of the lateral force – resisting system must be reinforced so that v + h 0.002, and v and h 0.0007 Type N mortar and masonry cement mortars are prohibited in the seismic force – resisting system Shear walls must meet minimum prescriptive requirements for reinforcement and connections (special reinforced) Other walls must meet minimum prescriptive requirements for horizontal and vertical reinforcement 41 TMS 402: Special Shear Walls roof connectors @ 48 in. max oc roof diaphragm #4 bar (min) within 16 in. of top of parapet Top of Parapet #4 bars around 24 in. or 40 db openings past opening #4 bar (min) within 8 in. of corners & ends of walls #4 bar (min) @ diaphragms continuous through control joint #4 bar (min) within 8 in. of all control joints control joint #4 bars @ 4 ft oc #4 bars @ 4 ft oc 42 TMS 402 Chapter 8: ASD calculated stresses from ASD loading combinations must not exceed allowable stresses allowable stresses are failure stresses, divided by a factor of safety varying from 2.5 to 4 calculated stresses: lower – case letters; allowable stresses: upper – case letters 1/3 increase NO LONGER PERMITTED in allowable stresses. Allowable stresses were recalibrated with 2011 & 2013 TMS 402. 43 TMS 402 8.1: General 8.1.1 Scope 8.1.2 Design strength 8.1.3 Anchor bolts embedded in grout 8.1.4 Shear stress in multiwythe masonry elements 8.1.5 Bearing stress 8.1.6 Development of reinforcement embedded in grout 44 TMS 402 8.1.3.3: Anchor Bolts Tension Bab 1.25 Apt f m' (8 - 1) and (8 - 3) Bap 0.6 f ed d b 120 lb ed d b d b ' m Bas 0.6 Ab f y (8 - 4) (8 - 2) and (8 - 5) 45 TMS 402 8.1.3.3: Anchor Bolts - Shear Same for Bent Bars and for Headed Bolts shear breakout Bvb 1.25 Apv (8 - 6) f Ab (8 - 7) masonry crushing Bvc 350 f m' 4 ' m shear pryout Bvpry 2.0 Bab 2.5 Apt f m' (8 - 8) steel yield Bvs 0.36 Ab f y (8 - 9) 46 TMS 402 8.1.3.3: Tension and Shear Anchor bolts subjected to combined shear and tension must satisfy a linear interaction equation ba bv 1 Ba Bv (8 10) 47 TMS 402 8.1.6: Development and Splice Required embedment length in tension addresses splitting from bar to surface and bar to bar ld 0.13 d b2 f y K f m' 12 in. (bars) , 6 in. (wires) (8 - 12) For epoxy – coated bars or wires, increase the above values by 50% 48 TMS 402 8.2: ASD Unreinforced Masonry 8.2.1 Scope 8.2.2 Design criteria 8.2.3 Design assumptions 8.2.4 Axial compression and flexure 8.2.5 Axial tension 8.2.6 Shear 49 TMS 402 8.2: Axial Compression Depends on slenderness (h / r) 2 h h 1 ' for 99 Fa f m 1 r 4 140 r 1 70 r Fa f m' 4 h 2 for h 99 r (8 - 16) (8 - 17) Also requires a stability check P (1 / 4) Pe Pe (8 - 15) Em I 2 h 2 e 1 0.577 r 3 (8 - 19) 50 TMS 402 8.2: Axial and Flexure Flexural compression 1 ' Fb f m 3 Flexural tension (Table 8.2.4.2) out - of - plane bending (traditional values) lower values for masonry cement and air - entrained portland cement - lime mortar higher values for grouted masonry Factors of safety around 2.5 Values for in – plane and out - of - plane flexural tension are equal 51 TMS 402 8.2: Shear Calculated shear stress VQ fv In b (8 - 20) Allowable stress is lowest of 1.5 f m' 120 psi Nv 0.45 An Where = 37 psi running bond or not running bond and fully grouted, = 60 psi for running bond and grouted , and = 15 psi otherwise 52 TMS 402 8.3: ASD Reinforced 8.3.1 Scope 8.3.2 Design assumptions 8.3.3 Steel reinforcement 8.3.4 Axial compression and flexure 8.3.5 Shear 53 TMS 402 8.3: Allowable Stresses Tension Grade 60 Wire joint reinforcement 32,000 psi 30,000 psi Maximum compressive stress in masonry from axial load plus bending must not exceed 0.45f’m Axial 2 h h ' Pa (0.25 f m An 0.65 Ast Fs ) 1 for 99 r 140r 70r Pa (0.25 f m' An 0.65 Ast Fs ) h 2 for h 99 r 54 TMS 402 8.3: Shear Shear stress is computed as: V fv Anv (8 - 24) Allowable shear stresses Fv Fvm Fvs g (8 - 25) g 10.75 for partially grouted shear walls, 1.0 otherwise. 55 TMS 402 8.3: Shear Allowable shear stresses limits: M / Vdv ≤ 0.25 Fv 3 f m' g M / Vdv 1 Fv 2 f m' g (8 - 26) (8 - 27) Can linear interpolate between limits 2 M g Fv 5 2 3 Vd v 56 TMS 402 8.3: Shear Allowable Shear Stress Resisted by the Masonry Special Reinforced Masonry Shear Walls Fv 1 P M ' 4 1.75 f m 0.25 , (8 - 29) 4 An Vd v All other masonry Fv 1 P M ' 4 1.75 f m 0.25 , (8 - 28) 2 An Vd v M/Vdv is positive and need not exceed 1.0. 57 TMS 402 8.3: Shear If allowable shear stress in the masonry is exceeded then: design shear reinforcement using Equation 8-30 and add Fvs to Fvm Av Fs d v Fvs 0.5 Anv s (8 - 30) Shear reinforcement is placed parallel the direction of the applied force at a maximum spacing of d/2 or 48 in. One - third of Av is required perpendicular to the applied force at a spacing of no more than 8 ft. 58 TMS 402 Chapter 9: SD Design strength must exceed required strength Action Reinforced Masonry combinations of flexure and axial load 0.90 Unreinforced Masonry 0.60 shear 0.80 0.80 bearing 0.60 0.60 59 TMS 402 9.1: General 9.1.1 Scope 9.1.2 Required strength 9.1.3 Design strength 9.1.4 Strength-reduction factors 9.1.5 Deformation requirements 9.1.6 Anchor bolts embedded in grout 9.1.7 Shear strength in multiwythe masonry elements 9.1.8 Nominal bearing strength 9.1.9 Material Properties 60 TMS 402 9.2: SD Unreinforced Masonry 9.2.1 Scope 9.2.2 Design criteria 9.2.3 Design assumptions 9.2.4 Nominal axial compression and flexure 9.2.5 Axial tension 9.2.6 Nominal shear strength 61 TMS 402 9.3: SD Reinforced 9.3.1 Scope 9.3.2 Design assumptions 9.3.3 Reinforcement requirements and details, including maximum steel percentage 9.3.4 Design of piers, beams and columns nominal axial and flexural strength nominal shear strength 9.3.5 Wall design for out – of – plane loads 9.3.6 Wall design for in – plane loads 62 TMS 402 9.3.2: Design assumptions continuity between reinforcement and grout equilibrium mu = 0.0035 for clay masonry, 0.0025 for concrete masonry plane sections remain plane elasto – plastic stress – strain curve for reinforcement tensile strength of masonry is neglected equivalent rectangular compressive stress block of stress 0.80 𝑓𝑚′ and depth of 0.80c 63 TMS 402 9.3.3: Reinforcement Bar diameter 1/8 nominal wall thickness Standard hooks and development length development length based on pullout and splitting In walls, shear reinforcement must be bent around extreme longitudinal bars Splices lap splices based on required development length welded and lap splices must develop 1.25 fy 64 TMS 402 9.3.3.5: Maximum reinforcement No upper limit when Mu/(Vudv) ≤ 1 and R ≤ 1.5 Other members, maximum area of flexural tensile reinforcement determined based on: Strain in extreme tensile reinforcement = 1.5 εy Axial forces determined from D + 0.75L + 0.525QE Compression reinforcement, with or without lateral restraining reinforcement, permitted to be included. Intermediate shear walls with Mu/(Vudv) ≥ 1, strain in extreme tensile reinforcement = 3εy Special shear walls with Mu/(Vudv) ≥ 1, strain in extreme tensile reinforcement = 4εy 65 TMS 402 9.3.3.5: Maximum reinforcement Three methods for checking maximum reinforcement Commentary equations Determine location of neutral axis based on specified strain condition only applicable for certain cases Find axial capacity and check that axial force from D + 0.75L + 0.525QE is less than axial capacity Determine location of neutral axis for given axial force, compute strain in extreme tension steel, and compare to minimum strain Usually requires using trial and error to find the location of the neutral axis 66 TMS 402 9.3.3.7: Joint reinforcement Seismic Design Categories (SDC) A and B At least two 3/16 in. wires Maximum spacing of 16 in. SDC C, D, E, and F; partially grouted walls At least two 3/16 in. wires Maximum spacing of 8 in. SDC C, D, E, and F; fully grouted walls At least four 3/16 in. wires Maximum spacing of 8 in. 67 TMS 402 Chapter 9.3.4: Shear Vn = (Vnm + Vns) γg Vn shall not exceed: 4 Mu Vn 5 2 Vu d v 3 Vn 6 Anv f m g Mu / Vu dv 0.25 Mu / Vu dv 1.0 Vn 4 Anv f m g linear interpolation between these extremes Anv f m g objective is to avoid crushing of diagonal strut γg – 0.75 for partially grouted shear walls and 1.0 otherwise 68 TMS 402 Chapter 9.3.4: Shear Vnm and Vns are given by Vnm Mu 4.0 1.75 Vu d v Anv f m' 0.25 Pu Av Vns 0.5 f y d v s (9 24) (9 25) Mu 1.0 Vu d v 69 TMS 402 Chapter 9.3.4.2: Beams Pu 0.05 An fm Mn 1.3 Mcr Unless As provided is at least 1/3 greater than required Maximum reinforcement: εs 1.5 εy Concrete masonry, f ʹm = 2000 psi, Grade 60 steel ρmax = 0.00952 70 TMS 402 Chapter 9.3.5: Out-of-Plane Capacity under combinations of flexure and axial load is based on the assumptions of TMS 402 Section 9.3.2 (interaction diagram) Single layer of steel, equivalent stress block in face shell or fully grouted. a As f y Pu / 0.80 f m b t sp t sp a As f y d M n Pu / As f y 2 2 For centered flexural reinforcement a M n Pu / As f y d 2 71 TMS 402 Chapter 9.3.5: Out-of-Plane Maximum reinforcement by 9.3.3.5 Nominal shear strength by 9.3.4.1.2 Three procedures for computing out – of – plane moments and deflections Second – order analysis Moment magnification method (new) Complementary moment method; additional moment from P – δ effects 72 TMS 402 Chapter 9.3.5: Out-of-Plane Moment Magnification M u M u ,0 1 Pu 1 Pe Pe 2 Em I eff h 2 Mu < Mcr: Ieff = 0.75In Mu ≥ Mcr: Ieff = Icr (9 31) (9 32) (9 33) 73 TMS 402 Chapter 9.3.5: Out-of-Plane Complementary Moment wu h 2 eu Mu Puf Pu u 8 2 Pu Puw Puf 5M u h 2 u 48 Em I n (9 27) (9 28) (9 29) 5M cr h 2 5M u M cr h 2 u 48 Em I n 48 Em I cr Eq. 9-29 for Mu < Mcr Eq. 9-30 for Mu ≥ Mcr (9 30) 74 TMS 402 Chapter 9.3.6: In-Plane Capacity under combinations of flexure and axial load is based on the assumptions of TMS 402 Section 9.3.2 (interaction diagram) Pn PLAN VIEW Strain εm Stress Mn c 0.8fʹm εs 75 TMS 402 Chapter 9.3.6: In-Plane Maximum reinforcement by 9.3.3.5 Vertical reinforcement not less than one–half the horizontal reinforcement Nominal shear strength by 9.3.4.1.2 76 TMS 402 Chapter 9.3.6: In-Plane Alternative approach to maximum reinforcement For walls expected to have flexural ductility in plane, provide confined boundary elements in hinging regions (another way of preventing toe crushing) Detailing requirements for boundary elements have yet to be developed 77 TMS 402 Chapter 9.3.6: In-Plane Alternative approach to maximum reinforcement Provide confined boundary elements in hinging regions (another way of preventing toe crushing) Detailing requirements for boundary elements have yet to be developed Boundary elements not required if: Pu 0.1 f m A g geometrically symmetrical sections Pu 0.05 f m A g geometrically unsymmetrical sections AND Mu 1 Vu l w OR Vu 3 An f m AND Mu 3 Vu lw 78 TMS 402 Chapter 10: Prestressed Prestressed masonry provisions were introduced in the 1999 TMS 402, and extensively updated in the 2005 TMS 402 Provisions address bonded and unbonded tendons Provisions address laterally restrained and laterally unrestrained tendons 79 TMS 402 Chapter 11: AAC Masonry AAC (Autoclaved Aerated Concrete) AAC is a lightweight, concrete - like material strength is specified by strength class of the AAC material alone (no prisms) density from 25 to 50 pcf compressive strength from 290 to 1100 psi strength class is the specified compressive strength in MPa (for example, Strength Class 4 has a specified compressive strength of 4 MPa, or 580 psi) AAC masonry units are laid using thin - bed, polymer modified mortar, which is stronger than the AAC material itself 80 TMS 402 Chapter 12: Veneer 12.1 General 12.2 Anchored Veneer 12.1.1 to 12.1.6 Scope & General design requirements 12.2.1 Alternate design method 12.2.2 Prescriptive requirements 12.3 Adhered Veneer 12.3.1 Alternate design method 12.3.2 Prescriptive requirements 81 TMS 402 Chapter 12: Anchored Veneer Prescriptive requirements of TMS 402 Section 12.2.2 Vertical support to meet TMS 402 Section 12.2.2.3 Thickness 2 – 5 / 8 in. Anchor requirements in TMS 402 Section 12.2.2.5 Corrugated sheet metal anchors Sheet metal anchors Wire anchors Joint reinforcement Adjustable anchors and spacings 82 TMS 402 Chap. 13: Glass Unit Masonry Prescriptive requirements for interior and exterior panels isolated panels and continuous bands standard (3 – 7 / 8 in.) or thin (3 – 1 / 8 in.) units fm not required for glass unit masonry designed by Chapter 13 Figure 13.2-1 sets maximum panel areas for different design wind pressures 83 TMS 402 Chap. 14: Partition Walls New in 2013 TMS 402 Rationally based using engineering analysis Includes prescriptive tables for 5 psf and 10 psf lateral loads Table 14.3.1(5) Maximum l/t1 and h/t1 for 5psf (.0.239 kPa) lateral load2 Mortar types Unit and Masonry Type Portland cement/lime or mortar cement Masonry cement or air entrained portland cement/lime M or S N M or S N Ungrouted and partially grouted hollow units3 26 24 22 18 Solid units and fully grouted hollow units3 40 36 33 26 1 t by definition is the nominal thickness of member 2 See Section 14.2.3.2 3 For non-cantilevered walls laterally supported at both ends. See Section 14.3.3 for cantilevered walls. 84 Design Methods Summary of design methods for typical masonry elements 85 Beam and Lintel Design Strength Design (Chapter 9) Allowable Stress (Chapter 8) • Allowable masonry stress: 0.45f’m • Allowable steel stress • 32 ksi, Grade 60 steel k 2 j 1 k (n ) 2n n 3 M fs As jd 2M fm b(kd )( jd ) • No min or max reinforcement requirements • Allowable shear stress 1 Fvm 2.25 f m 2 • • • • • mu = 0.0035 clay masonry mu = 0.0025 concrete masonry Masonry stress = 0.8f’m Masonry stress acts over a = 0.8c = 0.9 flexure; 0.8 shear 1 As f y M n As f y d 2 0 .8 f m b Vn 2.25 Anv f m • Minimum reinf: Mn ≥ 1.3Mcr • or As ≥ (4/3)As,req’d • Maximum reinf: s ≥ 1.5y max 0.80.8 f m m fy m s 86 Beam and Lintel Design Allowable Stress (Chapter 8) 1. Assume value of j (or k). Typically 0.85 < j < 0.95. 2. Determine a trial value of As. 𝐴𝑠 = 𝑀/ 𝐹𝑠 𝑗𝑑 Choose reinforcement. 3. Determine k and j; steel stress and masonry stress. 4. Compare calculated stresses to allowable stresses. 5. If masonry stress controls design, consider other options (such as change of member size, or change of f’m). Reinforcement is not being used efficiently. Strength Design (Chapter 9) 1. Determine a, depth of compressive stress block a d d2 2. Solve for As As 2M n 0.8 f m b 0.8 f m ba fy 3. ρmax = 0.285 𝑓𝑚′ 𝑓𝑦 for CMU Grade 60, f’m = 2 ksi ρmax = 0.00952 87 Beam and Lintel Design Assume compression controls. Determine kd. 2 d d 2 M kd 3 2 2 3Fbb If k < kb tension controls. Use iterative procedure to solve cubic equation. Start with kd from compression controlling. As If k ≥ kbal compression controls. kbal Fb Fb Fs n Grade 60 steel kbal = 0.312 Determine As. Fb (kd )b 2 As 1 nFb 1 k M k Fs d 1 3 As Fs n Fs b kd 2 2 2d Iterate. Use (kd)2 as new guess and repeat. 88 Interaction Diagrams Allowable Stress (Chapter 8) • For k > kbal • Set masonry strain = Fb/Em; = 0.0005 CMU • Find steel strain • For k < kbal • Set steel strain = Fs/Es; = 0.00110 for Grade 60 • Find masonry strain • Allowable axial load • h/r ≤ 99 h 2 Pa 0.25 f m An 0.65 Ast Fs 1 140 r Strength Design (Chapter 9) • Set masonry strain to εmu • Vary steel strain • Equivalent rectangular stress block • Nominal axial strength • h/r ≤ 99 h 2 Pn 0.8 0.80 f m An Ast f y Ast 1 140r • h/r > 99 70r Pn 0.80 0.80 f m An Ast f y Ast h • =0.9 • h/r > 99 70r Pa 0.25 f m An 0.65 Ast Fs h 2 89 2 Combined Bending and Axial Load Allowable Stress (Chapter 8) Assume compression controls. Determine kd. 2 d d 2 ( P ( d t / 2 ) M ) kd 3 2 3Fbb 2 If k ≥ kbal compression controls. Strength Design (Chapter 9) If steel has yielded a d d2 2Pu d t / 2 M u 0.8 f m b 0.8 f m ba Pu / As fy Fb (kd )b P 2 As 1 nFb 1 k If k < kb tension controls. Iterate to find As. 90 Combined Bending and Axial Load ASD, continued If k < kb tension controls. Use iterative procedure to solve cubic equation. Start with kd from compression controlling. t kd M P 2 3 As M M k Fs d 1 3 P As Fs n kd 2 Fs b 2 2d Iterate. Use (kd)2 as new guess and repeat. 91 Bearing Walls – OOP Loads Allowable Stress (Chapter 8) • No second-order analysis required • Use previous design procedure Strength Design (Chapter 9) • • • • Second order analysis required Assumes simple support conditions Assumes uniform load Assumes midheight moment is approximately maximum moment • Valid only for following conditions: 𝑃 • 𝑢 ≤ 0.05𝑓𝑚′ No height limit • 𝐴𝑔 𝑃𝑢 ≤ 0.20𝑓𝑚′ 𝐴𝑛 ℎ ≤ 30 𝑡 height limited by • Need to check maximum reinforcement limits 92 Strength Design – OOP Loads Deflection: Moment: wu h 2 eu Mu Puf Pu u 8 2 Pu Puw Puf 5M u h 2 u 48 Em I n 5M cr h 2 5M u M cr h 2 u 48 Em I n 48 Em I cr Puf = Factored floor load Puw = Factored wall load 3 t sp P bc 2 u d c I cr n As f y 2d 3 Deflection Limit M u M cr s 0.007h c M u M cr As f y Pu 0.64 f 'm b Calculated using allowable stress load combinations 93 Strength Design – OOP Loads Solve simultaneous linear equations: Mu > Mcr Mu < Mcr wu h 2 eu 5M cr Pu h 2 1 1 Puf 8 2 48 Em I n I cr Mu 5 Pu h 2 1 48 Em I cr u 5h 2 48 Em I cr wu h 2 I cr eu Puf M cr 1 2 8 In 5 Pu h 2 1 48 Em I cr wu h 2 e Puf u 2 Mu 8 5 Pu h 2 1 48 Em I n u wu h 2 eu Puf 8 2 5 Pu h 2 1 48 Em I n 5h 2 48 Em I n 94 Shear Walls - Shear Allowable Stress (Chapter 8) Fv Fvm Fvs Fvm Fvm M 1 4 . 0 1 . 75 2 Vd v P f m 0.25 An Strength Design (Chapter 9) M Vnm 4.0 1.75 u Vu d v M 1 4.0 1.75 4 Vd v P f m 0.25 An Special Reinforced Shear Walls AFd Fvs 0.5 v s An s Fv 3 f m Fv 2 f m M / Vd v 0.25 M / Vd v 1.0 Interpolate for 0.25 < (M/Vdv) < 1 0.8 Vn Vnm Vns Anv f m 0.25 Pu A Vns 0.5 v f y d v s Vn 6 Anv f m M u / Vu d v 0.25 Vn 4 Anv f m M u / Vu d v 1.0 M 4 Vn 5 2 u Anv f m 3 Vu d v 95 0.25 Mu 1.0 Vu d v Shear Walls – Max Reinforcement Allowable Stress (Chapter 8) Special reinforced shear walls having • M/(Vd) ≥ 1 and • P > 0.05f′mAn max nf m fy 2 f y n f m a = 1.5 ordinary walls; all others a = 3 intermediate walls with Mu/(Vudv)≥1 a = 4 special walls with Mu/(Vudv)≥1 Strength Design (Chapter 9) • Provide boundary elements, or • Limit reinforcement Boundary elements not required if: symmetrical sections Pu 0.1 f m A g Pu 0.05 f m A g unsymmetrical sections AND Mu 1 OR Vu l w Vu 3 An f m Mu 3 Vu lw Reinforcement limits: • Maximum stress in steel of αfy • Axial forces D+0.75L+0.525QE • Compression reinforcement, with or without lateral ties, permitted to be included 96 Shear Walls – Shear Capacity Design Allowable Stress (Chapter 8) Strength Design (Chapter 9) • Seismic design load required to be increased by 1.5 for shear • Design shear strength, Vn, greater than shear corresponding to 1.25 times nominal flexural strength, Mn (increases shear at least 1.39 times) • Except Vn need not be greater than 2.5Vu. (doubles shear) • Masonry shear stress reduced for special walls 97 Significant Changes in the 2013 TMS 402/602 Major Technical Changes • Partially grouted shear walls • Moment magnifier method • Unit strength tables 98 Partially Grouted Shear Walls: In-Plane Shear Strength ASD 8.3.5.1.2 Fv Fvm Fvs g SD V V V nm ns g 9.3.4.1.2 n γg = 0.75 for partially grouted shear walls and 1.0 otherwise 𝑉𝑒𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡𝑎𝑙 𝑉𝑛𝑜𝑚𝑖𝑛𝑎𝑙 Mean St Dev Fully grouted 1.16 0.17 Partially grouted 0.90 0.26 (Davis et al, 2010) (Minaie et al, 2010) 0.90 0.776 1.16 99 Partially Grouted Shear Walls: In-Plane Shear Strength Methods to calculate shear strength of partially grouted shear walls (Minaie et al, 2010) 𝑉𝑒𝑥𝑝𝑒𝑟𝑖𝑚𝑒𝑛𝑡𝑎𝑙 𝑉𝑛𝑜𝑚𝑖𝑛𝑎𝑙 Mean St Dev 2008 MSJC Code 0.90 0.26 Multiply shear strength by An/Ag 1.53 0.43 Using just face shells 1.77 0.78 Calculate net area, Anv, including grouted cells. Anv 2.5in192in 5(8in)(7.62in 2.5in) 685in 2 100 CMU Unit Strength Table TMS 602 Table 2 Net area compressive strength of concrete masonry, psi Type M or S Mortar Type N Mortar 1,700 --- 1,900 1,900 1,900 2,350 2,000 2,000 2,650 2,250 2,600 3,400 2,500 3,250 4,350 2,750 3,900 ---- Net area compressive strength of ASTM C90 concrete masonry units, psi (MPa) 101 Specified Compressive Strength, f′m Unit Strength (psi) f′m (psi) Type N mortar Type S mortar 1900 psi (C90-12) 2011 TMS 402/602 1350 1500 1900 psi (C90-12) 2013 TMS 402/602 1700 1900 2000 psi (C90-14) 2013 TMS 402/602 1750 2000 2013 TMS 402/602 references ASTM C90-12. To use f′m = 2000 psi (Type S), technically need to specify either: • ASTM C90-14, or • ASTM C90-12 but with a minimum unit strength of 2000 psi 102 Effect of f′m = 2000 psi vs. f′m = 1500 psi Allowable Stress Design • Small effect when allowable tension stress controls • Significant effect when allowable masonry stress controls Strength Design • Small effect on flexural strength • Significant effect on axial strength • Significant effect on maximum reinforcement requirements Both ASD and SD • 13% decrease in development and splice length • 15% increase in masonry shear strength Effectively changes γg to 0.87 for masonry shear strength 103 8 in. CMU wall Fully grouted Grade 60 steel Out-of-plane loading f′m = 2000 psi • • • • f′m = 1500 psi Maximum Reinforcement Spacing (inches) P/(bd) (psi) As (in2 per ft) #4 #5 #6 0 0.326 8 16 16 100 0.250 16 16 24 200 0.174 16 24 32 300 0.098 24 40 56 400 0.022 112 176 248 P/(bd) (psi) As (in2 per ft) #4 #5 #6 0 0.435 8 8 16 100 0.359 8 16 16 200 0.283 8 16 24 300 0.207 16 24 32 400 0.130 24 32 40 Spacing (inches) 104 Lap Splices Splice Length (in) Bar Size 2008 Code f’m = 1500 psi 2011 Code f’m = 1500 psi 2013 Code f’m = 2000 psi 3 15 12 12 4 20 14* 12* 5 25 23* 20* 6 43* 43* 37* 7 59* 59* 52* 8 91* 91* 79* 9 118* 118* 103* 8 in. CMU: bars centered in wall; fy=60 ksi * denotes K is controlled by masonry cover 105 Walls: Slenderness Effects 1. Complementary moment method a. Second-order moment directly added by P-δ b. Usually requires iteration c. Difficult for hand calculations for other than simple cases d. Basis for second-order analysis in computer programs e. Historical method used for masonry design 2. Second-order analysis a. Added in 2013 TMS 402 Code (9.3.5.4.3) b. Computer analysis 3. Moment magnification method a. Added in 2013 TMS 402 Code (9.3.5.4.3) b. Very general, but a bit conservative. 106 Moment Magnifier Method First Order Moment w h2 eu 5M cr Pu h 2 1 1 Puf 8 2 48 Em I n I cr 5 Pu h 2 1 48 Em I cr 5 u Complementary Moment Mu 48 M u M u , 0 (Equation 9-31) 1 Pu 1 Pe (Equation 9-32) Pe 2 Em I eff h2 (Equation 9-33) Always Negative = 0.104 ~ 1 = 0.101 𝜋2 Mu < Mcr: Ieff = 0.75In Mu ≥ Mcr: Ieff = Icr Moment magnifier is very general; no limitations 107 Moment Magnifier, Deflections Deflections determined either by: 1. Complementary moment method (simple support conditions) 2. Second-order analysis 3. First-order deflections magnified by 1/(1-P/Pe) Helpful Hints: Pf eh 2 5wh 4 0 384 Em I e 16 Em I e First-order deflection (simply supported wall): Rewriting TMS 402 OOP equations: Same as proposed by Bischoff, P. (2005). ”Reevaluation of Deflection Prediction for Concrete Beams Reinforced with Steel and Fiber Reinforced Polymer Bars.” J. Struct. Eng., 131(5), 752–767. Ie I cr M cr I cr 1 1 M In 108 Walls, OOP Loading, Summary • Traditional “slender wall” method has been retained • Two new options: very general • Second-order analysis • Moment magnification method • Loophole: • Second-order analysis methods allowed with no h/t or axial load restriction • Complementary moment method is a valid second-order analysis method • Therefore the restrictions on h/t and axial stress in 9.3.5.4.2 are meaningless 109 Many More Changes • Modulus of rupture values increased • Joint reinforcement can be primary shear reinforcement in strength design • Reinforcement and mortar requirements • Deep beam clarification • ASTM C-90 Normalized web area • Bond beams may be stepped or sloped • Tolerances for initial bed joint • Illustration of ‘d’ distance 110 Modulus of Rupture Values, Table 9.1.9.2 Masonry Type Mortar Type Portland cement/lime or mortar cement Normal to Bed Joints Solid Units Hollow Units* Ungrouted Fully Grouted Parallel to bed joints in running bond Solid Units Hollow Units Ungrouted and partially grouted Fully grouted Parallel to bed joints not laid in running bond Continuous grout section parallel to bed joints Other Masonry Cement M or S N M or S N 133 100 80 51 84 163 64 158 51 153 31 145 267 200 160 100 167 267 127 200 100 160 64 100 335 335 335 335 0 0 0 0 111 Modulus of Rupture: Effect of Increase Example: 8 inch CMU, bars at 48 inch, Type S masonry cement 2011: 5 ungrouted cells 1 grouted cell 153 psi f r 38 psi 57 psi 6 cells 6 cells 2013: 5 ungrouted cells 1 grouted cell 153 psi f r 51 psi 68 psi 6 cells 6 cells δ (inch) Load Combination Results from 18 ft high bearing wall trial design: out-of-plane loads fr = 57 psi fr = 68 psi D+0.6W 0.70 0.55 0.6D+0.6W 0.65 0.50 D+0.75(0.6W)+0.75Lr 0.38 0.22 Primary impact is to reduce calculated deflections under out-of-plane loading 112 Joint Reinforcement • Seismic Design Categories (SDC) A and B – At least two 3/16 in. wires (heavy duty joint reinforcement) – Maximum spacing of 16 in. • SDC C, D, E, and F; partially grouted walls – At least two 3/16 in. wires – Maximum spacing of 8 in. • SDC C, D, E, and F; fully grouted walls – At least four 3/16 in. wires – Maximum spacing of 8 in. Joint Reinforcement Equivalent Reinforcement Options Joint Reinforcement Equivalent Bar Reinforcement Replaces this Reinforcement 2 - 3/16 in. wires at 16 in. 0.0347 in2/ft #4 @ 56in.; #5 @ 80 in. 2 – 3/16 in. wires at 8 in. 0.0694 in2/ft #4 @ 32 in.; #5 @ 40 in. 4 – 3/16 in. wires at 8 in. 0.1388 in2/ft #4 @ 16 in.; #5 @ 24 in. Bar reinforcement yield stress = 60 ksi Joint reinforcement yield stress = 70 ksi Splice length: 48db (9.3.3.4 (e)) Anchor around edge reinforcing bar, either by bar placement between adjacent cross-wires or with a 90° bend in longitudinal wires and at least 3-in. bend extensions. (9.3.3.3.2.3) Reinforcement and Mortar Reinforcement • Mechanical splices in flexural reinforcement in plastic hinge zones of special reinforced walls: required to develop the specified tensile strength of the spliced bar, rather than 1.25fy (7.3.2.6 (e)) • Welded splices: reinforcement required to either conform to ASTM A706, or a chemical analysis and carbon equivalent of the reinforcement steel will need to be determined. (8.1.6.7.2, 9.3.3.4 (c)) Mortar • Masonry cement mortar is now permitted for fully grouted participating elements in Seismic Design Category (SDC) D and higher. (7.4.4.2.2) Deep Beam Clarification Beam depth Alternative beam depth 00 leff leff ASTM C90: Normalized Web Area ASTM C-90 reduced limits on web thickness of CMU units and added normalized web area Nominal Width (in.) Face Shell Thickness (in.) Web Thickness (in.) Normalized Web Area (in2/ft2) 3 and 4 ¾ ¾ 6.5 6 1 ¾ 6.5 8 1–¼ ¾ 6.5 Shear stresses in web need to be checked with unreinforced masonry if normalized web area is less than 27 in.2/ft2. (8.2.6.3 ,9.2.6.2) ASTM C90: Normalized Web Area Advantages of reduced web area: • Lighter weight units • easier to lay • minimal reduction in seismic weight, at least for partial grouted • Easier to lay; do not have to lift over bars with A and H blocks • Increased R-value of walls • more insulation • less thermal shorts Caution: • Reduces equivalent net thickness, which reduces fire ratings Practical minimum normalized web area to avoid breakage is about 11-12 in2/ft2. http://www.fendtproducts .com/products/concretemasonry-units/h-formblock.html Tolerances for Initial Bed Joint Footing tolerances • Level alignment of footings: ± ½ in. Does not work 2011 Bed joint tolerances • Initial bed joint: ¼ in. to ¾ in. Tolerance increased from ¾ in. to 1¼ in. when the first course of masonry is solid grouted and supported by a concrete foundation. Questions?