internal diffusion - University of Illinois at Urbana

advertisement

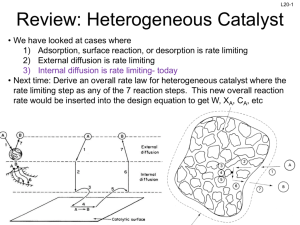

L21-1 Review: Heterogeneous Catalyst • We have looked at cases where 1) Adsorption, surface reaction, or desorption is rate limiting 2) External diffusion is rate limiting 3) Internal diffusion is rate limiting • Next goal: Derive an overall rate law for heterogeneous catalyst where the rate limiting step as any of the 7 reaction steps. This new overall reaction rate would be inserted into the design equation to get W, XA, CA, etc Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-2 Review: Internal Diffusion Effects in Spherical Catalyst Particles • Internal diffusion: diffusion of reactants or products from particle surface (pore mouth) to pellet interior • Concentration at the pore mouth will be higher than that inside the pore Step 1) Mole balance over the shell thickness r is: CAb External diffusion IN Internal diffusion CAs R - OUT + GEN = ACCUM WAr 4r 2 r WAr 4r 2 r r rA 4rm2r c 0 Volume of shell r Divide by -4/r & take limit as r →0 r’A: rxn rate per mass of catalyst c: catalyst density rm: mean radius between r and r - r d WAr r 2 dr r r 2 A Differential BMB in c 0 spherical catalyst particle Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. CAs Review: Diffusion & Rxn in Spherical Catalyst d WAr r 2 R dr r r+r r r 2 A c L21-3 0 (step 1, BMB) System at steady state, so EMCD: WB = -WA (otherwise A or B would accumulate) WA cDe dy A dC De A dr dr Rate law: mol mol n r '' A k C -r ' r '' A S A n A A 2 m s g cat s SA catalyst surface area mass of catalyst dCA 2 2 Solve for CA(r) & get Insert diffusion eq & d n D r r S k "C 0 C A n A WAr(r) from diffusion eq rate eq into BMB: dr e dr Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-4 Review:Dimensionless Variables dCA 2 2 d n D r r S k " C e C A n A 0 Put into dimensionless form dr dr n 2 n1 CA k " S R C k " S R C r n a c As As n2 n2 n a c CAs De CAs 0 R De R d2 2 d 2 n n 0 2 d d Boundary Conditions: =1 at =1 =finite at =0 Thiele modulus for rxn of nth order ≡ n Subscript n = reaction order n2 n is small: surface reaction is rate limiting n is large: internal diffusion is rate limiting The solution for CA 1 sinh 1 CAs sinh 1 a 1st order rxn: "a" surface rxn rate "a" diffusion rate CA C As small 1 medium 1 large 1 small 1: surface rxn control, significant amount of reactant R diffuses into pellet interior w/out reacting r=0 large 1: surface rxn is rapid, reactant is consumed very closed to the external surface of pellet (A waste of precious metal inside of pellet) Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-5 Review: Internal Effectiveness Factor, eta actual observed overall rate of rxn rate of reaction if entire interior surface were exposed to CAs & Ts r 'A mass of catalyst rA r ''A rAs r ''As r 'As mass of catalyst Effectiveness factor vs n knR2Sac CAsn1 n De 2 1 0.8 Reaction limited 0.6 • As particle diameter ↓, n ↓, →1, rxn is surface rxn limited 0.4 0.2 Internal diffusion limited 0.1 0.2 1 2 1 4 6 8 10 • As particle diameter ↑, n ↑, →0, rxn is diffusion limited Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-6 Review: Effectiveness Factor & Rxn Rate 3 2 1 coth 1 1 1 1 R ck1Sa De k1CAs Sa rA rAs R 1 1 surface-reaction-limited when 1 ,( 30) can be simplified to: De 3 3 , 1 1 R k1c Sa 1 is large, diffusion-limited reaction inside the pellet (external diffusion will have a negligible effect on the overall rxn rate because internal diffusion limits the rxn rate) rA 3 1 coth 1 1 rAs 12 rA k1CAs Sa When internal-diffusion-limited: De 3 rA k1CAs Sa R k1c Sa -rA De 3 R k1c Sa 3 De Sak1 CAs R c Overall rate for 1st-order rxn To increase the overall rate of a rxn limited by internal diffusion (1) decrease the radius R (2) increase the temperature (3) increase the concentration of A (4) increase the internal surface area Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-7 L21: Simultaneous Internal Diffusion & External Diffusion Goal: Derive a new rate eq that accounts for internal & external diffusion • -r’A is a function of reactant concentration • Reactant conc is affected by internal & external diffusion • Express reactant conc in terms of diffusion-related constants & variables →Use mole balance At steady-state: transport of reactants from bulk fluid to external catalyst surface is equal to net rate CAs CAb of reactant consumption in/on the pellet C(r) Molar rate of mass transfer from bulk fluid to external surface: MA WAr ac V reactor volume molar flux external surface area per unit reactor volume This molar rate of mass transfer to surface is equal to net rxn rate on & in pellet! MA rA external area internal area Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-8 Basic Molar Balance at Pellet Surface Flux: bulk to external surface x External S.A. Actual rxn rate per = unit total S.A. x external + internal S.A. rA ac V Sa bV ac: external surface area per reactor volume (m2/m3) V: reactor volume (m3) -r’’A: rate of reaction per unit surface area (mol/m2·s) Sa: surface area of catalyst per unit mass of catalyst (m2/g cat) b: bulk density, catalyst mass/ reactor volume b=c(1- : porosity of bed (void fraction) c: catalyst density WAr r R ac V MA WAr r R ac V rA ac V Sa b V MA WAr r R ac rA ac Sa b Typically external surface area <<< internal surface area MA WAr r R ac rA Sa b Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-9 Overall Molar Rate of Reaction Overall rxn rate = flux to surface = rxn rate on & in pellet MA WAr r R ac rA Sa b For external mass transport: WAr r R k c CAb CAs Since internal diffusion resistance is also significant, the reactant conc at the internal surface is lower that the reactant conc at the external surface: r ''A r ''As r ''A For a 1st order rxn: -r’’A=-k1CAs r ''As actual observed overall rate of rxn where the internal effectiveness factor: rxn rate if entire interior surface were exposed to C As & Ts Plug flux & 1st order rxn rate back into the mass balance: MA k c CAb CAs ac k1CAsSa b kcCAbac kcCAsac k1CAsSa b k c CAbac CAs k1Sa b k c ac Solve mass balance for CAs kcCAbac k1CAsSa b kcCAsac k c CAbac CAs k1Sa b k c ac Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-10 Overall Effectiveness Factors CAs k c ac CAb k c ac k1Sa b rA k1CAs rA Finally insert CAs into –r’’A k1k c acC Ab k c ac k1Sa b Overall rxn rate with internal & external diffusion Is this the overall rxn rate that we ALWAYS use for a surface reaction that has internal & external? (a) Yes, we should always use this rate equation for a surface reaction (b) No, we should only use this rate eq for processes that use spherical catalyst pellets (c) No, we should only use this rate eq for processes that that involve catalyst particles that have a constant density & even catalyst loading on the surface (d) No, we should only use this rate eq for 1st order irreversible reactions (e) b, c, & d Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-11 Overall Effectiveness Factors CAs k c ac CAb k c ac k1Sa b rA k1CAs rA Finally insert CAs into –r’’A k1k c ac CAb k c ac k1Sa b Overall rxn rate with internal & external diffusion Remember, the internal effectiveness factor (based on CAs) is: actual overall rate of reaction rate of rxn if entire interior surface were exposed to the external surface conditions The overall effectiveness factor (based on CAb) is defined as: Omega actual overall rate of reaction rate of reaction if entire interior surface were exposed to the bulk conditions k1CAb rA 1 k1Sa b k c ac rAb 1 k1Sa b k c ac k1CAb r ''A Put into design eq to account for internal & external diffusion rAb Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-12 Rxn Rate Variation vs Reactor Conditions External diffusion Internal diffusion Surface reaction Type of Limitation 12 13 Ud D D p r 'A k c AB Sh k c AB 2 0.6 dp dp DAB ck1Sa ck1Sa 3 rA kr CAsSa coth R 1 R De De 2 ck1Sa R De -r’A=kCA Variation of Reaction Rate with: Superficial velocity Particle size Temperature External U1/2 dp-3/2 Linear Internal Independent dp-1 Exponential Surface reaction Independent Independent Exponential Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-13 Consider an isothermal catalytic reaction in a PBR where there is no pressure drop and the catalyst pellets are uniformly packed & spherical. The kinetics are 1st order, and k, all physical parameters, and the inlet conditions (pure A in feed, A→ products) are given. Derive an equation for XA, taking into account the diffusion to and within each catalyst particle, but ignore diffusion down the length of the reactor. Rate must account for diffusion & dX A F r ' PBR design eq: A0 A be in terms of catalyst surface area dW 1. Put rate in terms of the unit surface area: -r 'A r ''A Sa -r 'A r ''Ab Sa 2. Account for diffusion limitations in rate eq: r ''A rAb 3. Rate is 1st order: r ''Ab kCAb -r 'A kCAbSa 4. Put into design eq: FA0 dX A kC Ab Sa dW 5. Put Cab in terms of XA: CAb CAb0 1 X A FA0 6. Integrate: dX A kSaCAb0 1 X A dW XA W kS C dX A dX A kSaCAb0 1 X A a Ab0 dW FA0 dW FA0 0 1 X A 0 Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-14 Consider an isothermal catalytic reaction in a PBR where there is no pressure drop and the catalyst pellets are uniformly packed & spherical. The kinetics are 1st order, and k, all physical parameters, and the inlet conditions (pure A in feed, A→ products) are given. Derive an equation for XA, taking into account the diffusion to and within each catalyst particle, but ignore diffusion down the length of the reactor. W kS C dX A a Ab0 dW ln 1 X kSaC Ab0 W 6. Integrate: A FA0 1 X F A A0 0 0 XA kSaCAb0 W ln 1 X 7. Solve for XA: A FA0 XA 1 e kSaCAb0 W FA0 1 XA e kSaCAb0 W FA0 kSa W XA 1 e 0 Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign. L21-15 1st XA for order rxn executed in an isothermal PBR packed with spherical catalyst particles with internal & external diffusion limitations kSa W XA 1 e 0 For same conditions, eq derived in Fogler (12-71) for XA at end of reactor of length L is: XA kSa bL U 1 e catalyst mass kg where : b = 3 reactor volume m L= z U=superficial velocity= 0 Ac Are these equations the same? They differ in the exponent: W bL W b L A c ? ? 0 0 0 0 Ac L A c V kSa W XA 1 e 0 kSa W 0 ? kSa bL U W W V V W W W b V ? ? 0 0 kSa bL U 1 e 0 0 0 0 XA Slides courtesy of Prof M L Kraft, Chemical & Biomolecular Engr Dept, University of Illinois at Urbana-Champaign.