Mass Transfer is Key (slides)

advertisement

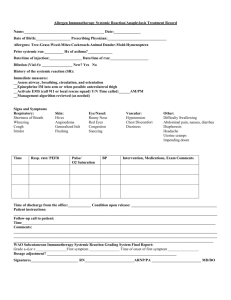

Carbon Capture Workshop Stanford, May 26, 2011 Mass Transfer is Key Ed Cussler Chemical Engineering University of Minnesota What are these towers, anyway? How Fat? How Tall? How Fat Depends On Flows How Tall Depends on Area, Rate concout concin e Kaz t=time a=area/volume K=mass transfer coefficient Area/Volume a is Simple How Tall Depends on Area, Rate concout concin e Kaz t=time a=area/volume K=mass transfer coefficient Rate Constant K is Complicated Rate Constant K is Complicated K Across a Gas Liquid Interface 1 K 1 k gas 1 kliq H Simple Mass Transfer k as f( Diffusion D) k DH l k D H t Fast Mass Transfer k as f( Rxn Rate ) k D Instantaneous Mass Transfer Not f(Rxn Rate) k rxn k w/o rxn DcNaOH 1 2 DcCO2 Overall Mass Transfer f(Reaction) Energy Efficiency vs. Amount Separated 1 efficiency, 0.75 yl = 0.05 0.5 yl = 0.1 0.25 0 0.001 yl = 0.5 0.01 amount in/out, y0 / yl 0.1 Conclusions 1. Use Largest Possible Area/Volume a. 2. Use Largest Possible H. 3. For Absorption, Use Reactive Liquid. 4. Don’t Fuss Over Diffusion. 5. Watch Energy Efficiency . 3 RO Power Consumption (kWh/m ) RO is Approaching a Similar Limit 25 20 4 3 2 15 1 0 10 2000 2004 2006 5 0 1970 1980 1990 2000 2004 2006 Year Two Exchangers spray tower shell and tube 3 RO Power Consumption (kWh/m ) RO is Approaching a Similar Limit 25 20 4 3 15 2 1 10 0 2000 2004 2006 5 0 1970 1980 1990 2000 2004 2006 Year Mass-transfer area of structured packing Tsai et al (AIChE J, May ’11) • Abstract • The mass-transfer area of nine structured packings was measured via absorption of CO2 from air into 0.1 kmol/m3 NaOH. The masstransfer area was most strongly related to the specific area (125–500 m2/m3), and liquid load (2.5–75 m3/m2·h). Surface tension (30–72 mN/m) had a weaker effect. Gas velocity (0.6– 2.3 m/s), liquid viscosity (1–15 mPa·s), and flow channel configuration had essentially no impact.