Production and Operations Management: Manufacturing and Services

advertisement

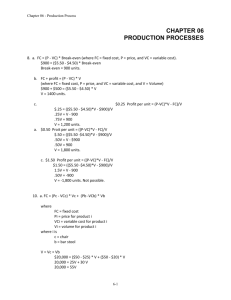

Process Management Class 3: 2/2/11 6-2 OBJECTIVES Process Analysis Process Flowcharting Types of Processes Process Performance Metrics Manufacturing Processes Service Processes Business Process Reengineering PROCESS MANAGEMENT Processes relate to work that is ongoing and repetitive Process management concepts and methods can be applied to improve manufacturing, service, and business processes Effort is placed trying to reduce cost, increase throughput, and improve quality 6-4 PROCESS ANALYSIS TERMS Process: Is any part of an organization that takes inputs and transforms them into outputs Cycle Time: Is the average successive time between completions of successive units Utilization: Is the ratio of the time that a resource is actually activated relative to the time that it is available for use 6-5 PROCESS FLOWCHARTING DEFINED Process flowcharting is the use of a diagram to present the major elements of a process The basic elements can include tasks or operations, flows of materials or customers, decision points, and storage areas or queues It is an ideal methodology by which to begin analyzing a process 6-6 Flowchart Symbols Purpose and Examples Examples: Giving an Tasks or operations admission ticket to a customer, installing a engine in a car, etc. Examples: How much Decision Points change should be given to a customer, which wrench should be used, etc. 6-7 Flowchart Symbols Purpose and Examples Storage areas or queues Examples: Sheds, lines of people waiting for a service, etc. Flows of materials or customers Examples: Customers moving to a seat, mechanic getting a tool, etc. 6-8 TYPES OF PROCESSES Single-stage Process Stage 1 Multi-stage Process Stage 1 Stage 2 Stage 3 6-9 TYPES OF PROCESSES (CONTINUED) A buffer refers to a storage area between stages where the output of a stage is placed prior to being used in a downstream stage Multi-stage Process with Buffer Buffer Stage 1 Stage 2 6-10 OTHER PROCESS TERMINOLOGY Blocking Occurs when the activities in a stage must stop because there is no place to deposit the item just completed If there is no room for an employee to place a unit of work down, the employee will hold on to it not able to continue working on the next unit Starving Occurs when the activities in a stage must stop because there is no work If an employee is waiting at a work station and no work is coming to the employee to process, the employee will remain idle until the next unit of work comes 6-11 OTHER PROCESS TERMINOLOGY (CONTINUED) Bottleneck Occurs when the limited capacity of a process causes work to pile up or become unevenly distributed in the flow of a process If an employee works too slow in a multi-stage process, work will begin to pile up in front of that employee. In this is case the employee represents the limited capacity causing the bottleneck. Pacing Refers to the fixed timing of the movement of items through the process 6-12 OTHER TYPES OF PROCESSES Make-to-order Only activated in response to an actual order Both work-in-process and finished goods inventory kept to a minimum Make-to-stock Process activated to meet expected or forecast demand Customer orders are served from target stocking level 6-14 PROCESS PERFORMANCE METRICS Capacity: maximum output of a process or resource measured in units/time: a rate Operation time = Setup time + Run time Setup time: the length of time required to changeover from one product to another (assumes products are produced in batches) Throughput time = Average time for a unit to move through the system 6-15 PROCESS PERFORMANCE METRICS (CONTINUED) Cycle time = Average time between completion of units Throughput rate = 1___ Cycle time Utilization of an operation = Demand/Capacity 6-16 CYCLE TIME EXAMPLE Suppose you had to produce 600 units in 80 hours to meet the demand requirements of a product. What is the cycle time to meet this demand requirement? Answer: There are 4,800 minutes (60 minutes/hour x 80 hours) in 80 hours. So the average time between completions would have to be: Cycle time = 4,800/600 units = 8 minutes. BREAD-MAKING QUESTIONS What is the bottleneck when one breadmaking line is used? What is the capacity of the process? What is the utilization of packaging? What is the throughput time? What happens to capacity and utilization when two bread-making lines are used? What is the bottleneck? 6-19 PROCESS THROUGHPUT TIME REDUCTION Perform activities in parallel Change the sequence of activities Reduce interruptions 7-20 BASIC WORK FLOW STRUCTURES Project layout – fixed position; construction, movie lots Workcenter (job shop) – similar equipment grouped together; machine shop Manufacturing cell – similar set of processes for a limited range of products Assembly Line – discrete parts move through workstations; toys, appliances, cars Continuous process – flow vs discrete, flows a set sequence of steps; oil, rubber, chemicals PROCESS TYPES Continuous Assembly Line Job Shop Cell Project CONTINUOUS PROCESS Highly standardized products in large volumes Often these products have become commodities Typically these processes operate 24 hours/day seven days/week Objective is to spread fixed cost over as large a volume as possible CONTINUOUS PROCESS CONTINUED Starting and stopping a continuous process can be prohibitively expensive Highly automated and specialized equipment used Layout follows the processing stages Output rate controlled through equipment capacity and flow mixture rates CONTINUOUS PROCESS CONTINUED Low labor requirements Often one primary input Initial setup of equipment and procedures very complex 24 ASSEMBLY LINE Similar to continuous process except discrete product is produced Heavily automated special purpose equipment High volume - low variety Both services and products can use flow shop form of processing A GENERALIZED ASSEMBLY LINE OPERATION ADVANTAGES OF THE ASSEMBLY LINE Low unit cost specialized high volume equipment bulk purchasing lower labor rates low in-process inventories simplified managerial control DISADVANTAGES OF ASSEMBLY LINE Variety of output difficult to obtain Difficult to change rate of output Minor design changes may require substantial changes to the equipment Worker boredom and absenteeism Work not very challenging Vulnerable to equipment breakdowns DISADVANTAGES OF ASSEMBLY LINE CONTINUED Line balanced to slowest element Large support staff required Planning, design, and installation very complex task Difficult to dispose of or modify special purpose equipment ASSEMBLY LINE LAYOUT Objective is to assign tasks to groups The work assigned to each group should take about the same amount of time to complete Final assembly operations with more labor input often subdivided easier Paced versus unpaced lines JOB SHOP High variety - low volume Equipment and staff grouped based on function Each output processed differently A GENERALIZED JOB SHOP OPERATION 32 ADVANTAGES OF THE JOB SHOP Flexibility to respond to individual demands Less expensive general purpose equipment used Maintenance and installation of general purpose equipment easier General purpose equipment easier to modify and therefore less susceptible to becoming obsolete ADVANTAGES OF THE JOB SHOP CONTINUED Dangerous activities can be segregated from other operations Higher skilled work leading to pride of workmanship Experience and expertise concentrated Pace of work not dictated by moving line Less vulnerable to equipment breakdowns DISADVANTAGES OF THE JOB SHOP General purpose equipment is slower Higher direct labor cost High WIP inventories High material handling costs Management control very difficult THE CELL FORM Combines flexibility of job shop with low costs and short response times of flow shop Based on group technology First identify part families Then form machine cells to produce part families CONVERSION OF A JOB SHOP LAYOUT TO A CELLULAR LAYOUT 37 ORGANIZATION OF MISCELLANEOUS PARTS INTO FAMILIES 38 ADVANTAGES OF CELLULAR PRODUCTION Reduced machine setup times increased capacity economical to produce in smaller batch sizes smaller batch sizes result in less WIP less WIP leads to shorter lead times shorter lead times increase forecast accuracy and provide a competitive advantage Parts produced in one cell ADVANTAGES OF CELLULAR PRODUCTION CONTINUED Capitalize on benefits of using worker teams Minimal cost to move from job shop to cellular production (e.g. EHC) Can move from cellular production to “miniplants” DISADVANTAGES OF CELLULAR PRODUCTION Volumes too low to justify highly efficient high volume equipment Vulnerable to equipment breakdowns Balancing work across cells Does not offer the same high degree of customization as the job shop CELLULAR LAYOUT Teams of workers and equipment to produce families of outputs Workers cross-trained Nominal cells versus physical cells. Remainder cell Cell formation methods production flow analysis PROJECT OPERATIONS Large scale Finite duration Nonrepetitive Multiple interdependent activities Offers extremely short reaction times 43 7-44 PRODUCT-PROCESS MATRIX SELECTION OF TRANSFORMATION SYSTEM BY STAGE OF LIFE CYCLE 45 7-46 BREAK-EVEN ANALYSIS A standard approach to choosing among alternative processes or equipment Model seeks to determine the point in units produced (and sold) where we will start making profit on the process or equipment Model seeks to determine the point in units produced (and sold) where total revenue and total cost are equal 7-47 BREAK-EVEN ANALYSIS (CONTINUED) Break-even Demand= Purchase cost of process or equipment Price per unit - Cost per unit or Total fixed costs of process or equipment Unit price to customer - Variable costs per unit This formula can be used to find any of its components algebraically if the other parameters are known 7-48 BREAK-EVEN ANALYSIS (CONTINUED) Example: Suppose you want to purchase a new computer that will cost $5,000. It will be used to process written orders from customers who will pay $25 each for the service. The cost of labor, electricity and the form used to place the order is $5 per customer. How many customers will we need to serve to permit the total revenue to breakeven with our costs? Break-even Demand: = Total fixed costs of process or equip. Unit price to customer – Variable costs =5,000/(25-5) =250 customers 7-49 MANUFACTURING PROCESS FLOW DESIGN A process flow design can be defined as a mapping of the specific processes that raw materials, parts, and subassemblies follow as they move through a plant The most common tools to conduct a process flow design include assembly drawings, assembly charts, and operation and route sheets 7-50 EXAMPLE: ASSEMBLY CHART (GOZINTO) – PLUG ASSEMBLY From Exhibit 7.4 4 5 6 7 Lockring Spacer, detent spring SA-2 Rivets (2) A-2 Spring-detent A-5 Component/Assy Operation Inspection 8-51 SERVICE BUSINESSES A service business is the management of organizations whose primary business requires interaction with the customer to produce the service Facilities-based services: Where the customer must go to the service facility Field-based services: Where the production and consumption of the service takes place in the customer’s environment 8-52 THE CUSTOMER CENTERED VIEW A philosophical view that suggests the organization exists to serve the customer, and the systems and the employees exist to facilitate the process of service. The Systems The Service Strategy The Customer The People 8-53 SERVICE-SYSTEM DESIGN MATRIX Degree of customer/server contact High Buffered core (none) Permeable system (some) Reactive system (much) Low Face-to-face total customization Face-to-face loose specs Sales Opportunity Face-to-face tight specs Production Efficiency Phone Internet & Contact on-site technology Mail contact Low High 8-54 CHARACTERISTICS OF WORKERS, OPERATIONS, AND INNOVATIONS RELATIVE TO THE DEGREE OF CUSTOMER/SERVICE CONTACT 8-55 EXAMPLE OF SERVICE BLUEPRINTING Standard execution time 2 minutes Brush shoes 30 secs Total acceptable execution time 5 minutes Seen by customer Line of visibility Not seen by customer but necessary to performance Clean shoes 45 secs Apply polish 30 secs Fail point Buff Collect payment 45 secs 15 secs Wrong color wax Materials (e.g., polish, cloth) Select and purchase supplies 8-56 SERVICE FAIL-SAFING POKA-YOKES (A PROACTIVE APPROACH) Keeping a mistake from becoming a service defect How can we failsafe the three Ts? Task Treatment Tangibles 8-57 THREE CONTRASTING SERVICE DESIGNS The production line approach (ex. McDonald’s) The self-service approach (ex. automatic teller machines) The personal attention approach (ex. Ritz-Carlton Hotel Company) 8-58 MANAGING CUSTOMER INTRODUCED VARIATION •Arrival variability •Request variability •Capability variability •Effort variability •Subjective preference variability 8-59 ACCOMMODATION STRATEGIES Classic accommodation – extra employees or additional employee skills Low cost accommodation – use low cost labor, outsource, self-service Classic reduction – more self-service, reservations, adjust expectations Uncompromised reduction – develop procedures for good service, minimizing variation impact 8-60 CHARACTERISTICS OF A WELL-DESIGNED SERVICE SYSTEM 1. Each element of the service system is consistent with the operating focus of the firm 2. It is user-friendly 3. It is robust 4. It is structured so that consistent performance by its people and systems is easily maintained 8-61 CHARACTERISTICS OF A WELL-DESIGNED SERVICE SYSTEM (CONTINUED) 5. It provides effective links between the back office and the front office so that nothing falls between the cracks 6. It manages the evidence of service quality in such a way that customers see the value of the service provided 7. It is cost-effective 8-62 SERVICE GUARANTEES AS DESIGN DRIVERS Recent research suggests: Any guarantee is better than no guarantee Involve the customer as well as employees in the design Avoid complexity or legalistic language Do not quibble or wriggle when a customer invokes a guarantee Make it clear that you are happy for customers to invoke the guarantee BUSINESS PROCESS DESIGN (REENGINEERING) DIVISION OF LABOR CONCEPT Work broken down into its simplest most basic tasks Performing same task facilitates attaining greater skill No time lost switching to another task Workers well positioned to improve tools and techniques DIVISION OF LABOR CONCEPT CONTINUED Division of labor concept not challenged until recently despite dramatic changes in technology Quality, innovation, service, and value more important than cost, growth, and control PROCESS Set of activities that taken together produce a result of value to the customer Organizing on basis of processes Eliminate delays and errors when work is handed off Capture information once and at source When people closest to process perform work, there is little need for management overhead BUSINESS PROCESS DESIGN (BPD) The fundamental rethinking and radical redesign of business processes to bring about dramatic improvements in performance Hammer, M. and Stanton, S. The Reengineering Revolution, Harper Business, 1995. RADICAL Profoundly change the way work performed Not concerned with making superficial changes Get to root Get rid of old Reinventing, not improving REDESIGN BPD is about designing how work is done Smart, capable, well trained, highly motivated employees mean little if the way work is performed is poorly designed PROCESS All organizations perform processes Customers not interested in individual activities but rather overall results Few of them are organized on the basis of processes Thus, processes tend to go unmanaged Team approach one way this addressed DRAMATIC Quantum leaps in performance, not marginal or incremental improvements Breakthroughs in performance IBM CREDIT EXAMPLE 72 IBM CREDIT EXAMPLE CONTINUED Order logged by 1 of 14 people in conference room Carted upstairs to credit department Information entered into computer to check borrower’s creditworthiness Results written on piece of paper IBM CREDIT EXAMPLE CONTINUED Business practices department modified standard loan covenant in response to customer requests Used its own computer system Pricer keyed data into PC to determine appropriate interest rate Administrator converted to quote letter and Fedexed to field sales rep. IBM CREDIT EXAMPLE CONTINUED Average time to process a request was 6 days Could take as long as 2 weeks Actual processing time 90 minutes Deal Structurer Turnaround time 4 hours Number of deals processed increased 100 times with small reduction in head count