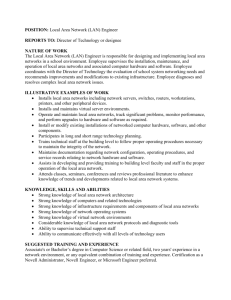

ADA ESTELLA WHITNEY

advertisement

MICHAEL B GRAHAM 205 Timberlake Dr. Azle, TX 76020 206.854.0044 / 206.650.7552 mandmgraham@aol.com SUMMARY Versatile and technically proficient mechanical structural engineer qualified by over thirty five years of professional experience in multiple aspects of aerospace; from structural repairs to mechanical design systems. Combining technical, analytical, and engineering expertise to provide rapid responses and ultimately providing outstanding customer service. SKILLS AND QUALIFICATIONS - Knowledge in CAD Design Systems - Ability to work independently and with a team - Effective analytical skills & organizational skills - Excellent people and customer support skills - Ability to multi-task in a fast paced environment - Career focused with high work ethics CAREER EXPERIENCE AVIATION TECHNICAL SERVICES, MRO. EVERETT WA APRIL 2015 – PRESENT Repair Engineer Preparing repairs for Southwest Aircraft being repaired and overhauled for Boeing approval. THE BOEING COMPANY, Duwamish, Washington May 2004 – April 2013 Structural Engineer Boeing Operations Center / Rapid Response Center supporting repairs outside of the Structural Repair Manual (SRM) allowables; close coordination with engineering Designated Engineering Representatives (DER) / Airworthiness Representatives (AR) on all Boeing Aircraft type including 737, 747, 757, 767, 777…. Coordination of repairs on nightshift with Spirit, Wichita for Customer 737 New Generation Aircraft. AIRBUS, Chester, England October 2002 – May 2004 Material Review Board (MRB) Liaison Design/ Concessions Engineer Performing Non-Conformance activities / structural repairs on Airbus A340-600 Wing Structures. GOODRICH AEROSPACE, Tucson, Arizona January 2000 – January 2002 MRB Liaison Engineer Onsite at Hamilton Av. In Tucson and Commercial Jet located in Miami as the Engineering Representative. Responsible for all aspects of the Boeing Super 27 (Valsan) Re-engining Modification (Re-structuring Boeing 727's to accept larger MD80 Engines). NORDAM REPAIR FACILITY, Fort Worth, Texas May 1999 – January 2000 MRB Liaison Engineer/Repair Design Repairing aircraft flight control surfaces (metallic), aircraft doors and 737 engine hush kits outside of the SRM allowables with close coordination with engineering DERs. THE BOEING COMPANY, Renton, Washington May 1996 – April 1999 MRB Liaison Engineer Assigned to all aspects of the 737 / 757 pressurized doors installation; supporting MRB rejection tag activity. FLIGHT STRUCTURES, Arlington, Washington March 1995 – May 1996 Design Engineer Responsible for designing the pressure seal, retainer and mechanism support structure for the new main deck cargo door for the A300 freighter conversion using Anvil CAD including floor structure conversion and 757 stowage bins. THE BOEING COMPANY, Renton, Washington June 1989 – March 1995 MRB Design/Liaison Engineer Responsible for design and production revisions on the 757 number 2 passenger door structure and mechanism. Mechanisms included bearing, seal and spring failure investigation. Supported MRB activity from the door shop, through installation to final assembly. This included all aspects of the main deck cargo door for the UPS package freighter. MTU AERO ENGINES, Munich, Germany December 1988 – May 1989 Project Design Engineer Design of the EJ200 engine compressor rig and instrumentation for the European fighter. ALFA ROMEO AVIO, Naples, Italy March 1988 – December 1988 Design Engineer Design of the auxiliary power unit combustion chamber rig and instrumentation for the European fighter aircraft using Computervision CADDS 4x. THE BOEING COMPANY, Seattle, Washington (Thompson Site) February 1984 – March 1988 Mechanical Design Engineer Responsible for design and installation of the environmental control systems (pneumatics systems, including engine bleed, pre-cooler, pilot control valves, engine start, anti-ice, cabin air and thrust reverser) onto the GE CF6-80C engine used on the new 747 / 767. Supported 757 door group designing no-draft precision castings and forgings, their machining and liaison with their forging house. For 5 months, primary and secondary 737-400 wing structure design including composites. MTU AERO ENGINES, Munich, Germany March 1983 – February 1984 Design Engineer Responsible for the design of engine build and maintenance tooling for the joint MTU / Pratt engine venture. FLIGHT REFUELING LIMITED, Wimborne, England July 1982 – March 1983 Design Engineer Responsible for the design and installation of solid fuel rejectable rockets onto the wing of a subsonic aerial target (drone) and design of its launch stand. THE BOEING COMPANY, Renton, Washington August 1980 – July 1982 Design Engineer Redesigning the engine strut and side cowl supports for acceptance of the new P&W JT9D-7R4 Engine. Involved with the design of the environmental control system (pneumatics) for the P&W 2037 engine on the new Boeing 757 with the aide of Gerber IDS CAD. MTU AERO ENGINES, Munich, Germany July 1978 – August 1980 Design Engineer Design of RB199 ground and test equipment and repair design of flight engines. The RB199 engine that is used on the MRSA Tornado Aircraft and work has involved close collaboration with Rolls Royce in England and Fiat in Italy. PLESSEY MARINE, Newport, Wales UK May 1977– July 1978 Printed Circuit Board (PCB)Designer/Electro-Mechanical Packaging Engineer Design and installation of multi-layer printed circuit boards for Navy submarines. . ROLLS ROYCE, May 1969– May 1977 Engineering Design Specialist Detail Design of engine components for the Olympus 593 (Concorde) and the Pegasus 101 (Harrier Jump Jet) EDUCATION Degree ROLLS ROYCE TECHNICAL COLLEGE, BRISTOL ENGLAND, - DECEMBER 1973. FULL TECHNICAL CERTIFICATE, PARTS 1, 2 AND 3. (B.S EQUIVALENT) ROLLS ROYCE TECHNICAL COLLEGE, BRISTOL ENGLAND, - DECEMBER 1973. 4 Year Indentured Apprenticeship in Aero-Engine Design