IZMIR INSTITUTE OF TECHNOLOGY

advertisement

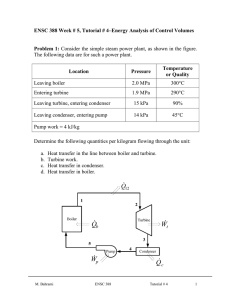

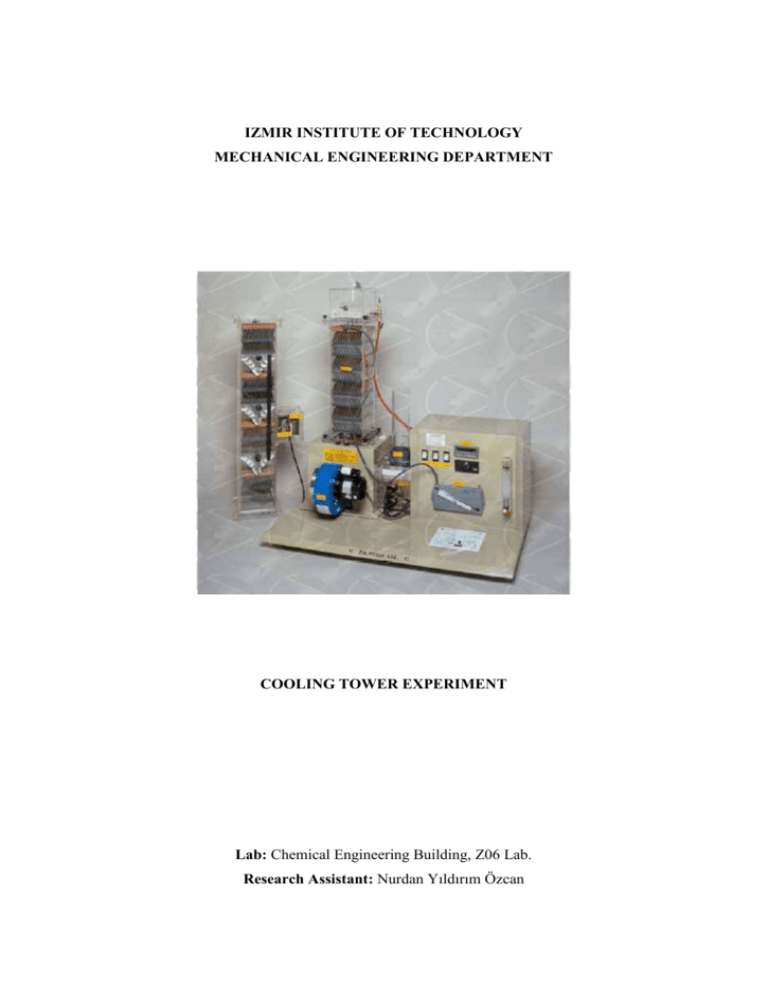

IZMIR INSTITUTE OF TECHNOLOGY MECHANICAL ENGINEERING DEPARTMENT COOLING TOWER EXPERIMENT Lab: Chemical Engineering Building, Z06 Lab. Research Assistant: Nurdan Yıldırım Özcan Purpose of the experiment Aim of this experiment is to give students an appreciation of the construction, design and operational characteristics of a modern evaporative cooling system. The cooling tower is also an excellent example of an “open system” through which two streams of fluid flow (water and air) and in which there is a mass transfer from one stream to the other. Figure 1: Cooling tower flow diagram. DESCRIPTION Water Circuit: Warm water is pumped from the load tank through the control valve and water flow meter to the column cap. After its temperature is measured, the water is uniformly distributed over the top packing deck and, as it spreads over the plates, a large thin film of water is exposed to the air stream. During its downward passage through the packing, the water is cooled, largely by the evaporation of a small portion of the total flow. Collected data will be given to you in Excel format. First of all you will plot the following graphs. Fuel flow vs time Boiler temperature vs time Boiler pressure vs time Turbine inlet/outlet pressure vs time Turbine inlet/outlet temperature vs time Generator dc amps output vs time Generator dc voltage output vs time Turbine rpm vs time In the graphs you will choose a steady state period for 5-10 minutes. For this period note the following data to be able to use in calculations: Atmospheric pressure Initial boiler fill amount Fuel flow Boiler pressure Turbine inlet pressure Turbine inlet temperature Turbine outlet temperature Turbine outlet pressure Steady State Condensation amount For analysis assume a steady state, steady flow condition. Changes in kinetic and potential energy are negligible. Calculate the listed data above: Heat flow out of boiler Work rate of the turbine Efficiency of electric generator Heat flow rate out of the system at the condenser Condenser efficiency Total system efficiency