Östrand Pulp Mill: New Recovery Boiler & Turbine - Siemens & Andritz

advertisement

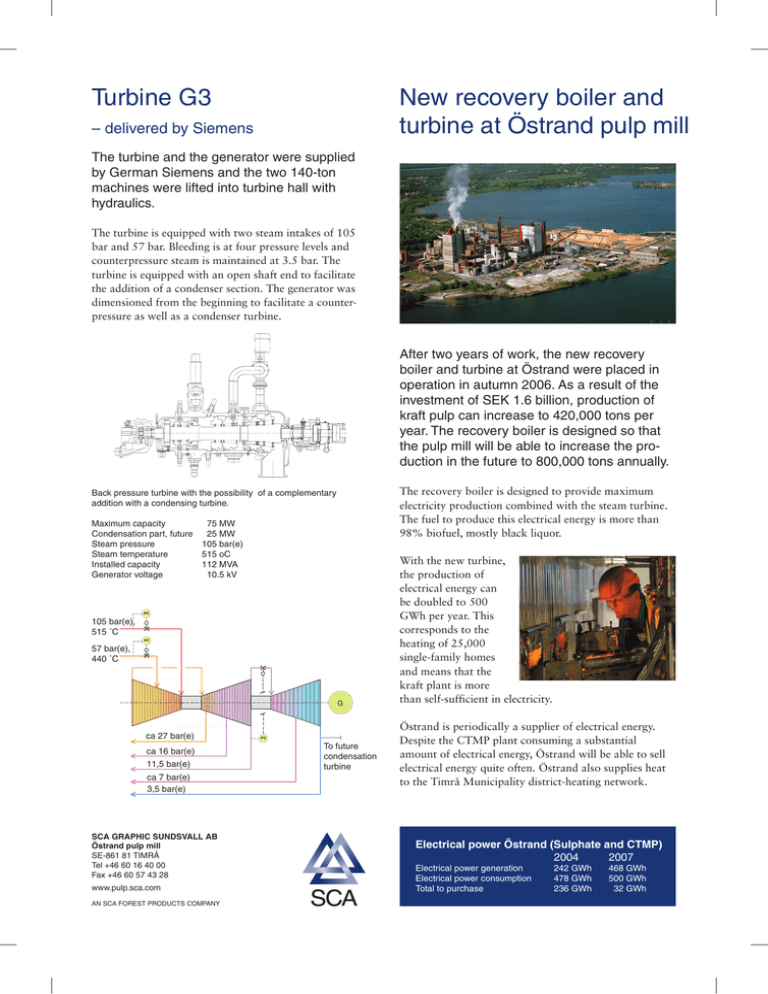

Turbine G3 New recovery boiler and turbine at Östrand pulp mill – delivered by Siemens The turbine and the generator were supplied by German Siemens and the two 140-ton machines were lifted into turbine hall with hydraulics. The turbine is equipped with two steam intakes of 105 bar and 57 bar. Bleeding is at four pressure levels and counterpressure steam is maintained at 3.5 bar. The turbine is equipped with an open shaft end to facilitate the addition of a condenser section. The generator was dimensioned from the beginning to facilitate a counterpressure as well as a condenser turbine. After two years of work, the new recovery boiler and turbine at Östrand were placed in operation in autumn 2006. As a result of the investment of SEK 1.6 billion, production of kraft pulp can increase to 420,000 tons per year. The recovery boiler is designed so that the pulp mill will be able to increase the production in the future to 800,000 tons annually. The recovery boiler is designed to provide maximum electricity production combined with the steam turbine. The fuel to produce this electrical energy is more than 98% biofuel, mostly black liquor. Back pressure turbine with the possibility of a complementary addition with a condensing turbine. Maximum capacity Condensation part, future Steam pressure Steam temperature Installed capacity Generator voltage 75 MW 25 MW 105 bar(e) 515 oC 112 MVA 10.5 kV PC 105 bar(e), 515 ˚C PC 57 bar(e), 440 ˚C G ca 27 bar(e) ca 16 bar(e) 11,5 bar(e) ca 7 bar(e) 3,5 bar(e) SCA GRAPHIC SUNDSVALL AB Östrand pulp mill SE-861 81 TIMRÅ Tel +46 60 16 40 00 Fax +46 60 57 43 28 www.pulp.sca.com AN SCA FOREST PRODUCTS COMPANY PC To future condensation turbine With the new turbine, the production of electrical energy can be doubled to 500 GWh per year. This corresponds to the heating of 25,000 single-family homes and means that the kraft plant is more than self-sufficient in electricity. Östrand is periodically a supplier of electrical energy. Despite the CTMP plant consuming a substantial amount of electrical energy, Östrand will be able to sell electrical energy quite often. Östrand also supplies heat to the Timrå Municipality district-heating network. Electrical power Östrand (Sulphate and CTMP) 2004 2007 Electrical power generation Electrical power consumption Total to purchase 242 GWh 478 GWh 236 GWh 468 GWh 500 GWh 32 GWh Recovery boiler 6 – delivered by Andritz Östrand’s new soda recovery boiler was delivered by Andritz and the boiler building is 77 meters high. A steam temperature of 515 oC was selected so that the boiler and the turbine would be able to deliver maximum electricity production. Consequently, the superheaters were over-dimensioned and produced in specialty steel. Since the system’s degree of electrical output is prioritized, the amount of high-pressure steam has been maximized. This is accomplished through extended preheating of the feed water and combustion air in several stages. Sootblowing steam is recovered from a bleed duct in the turbine. The boiler is fed combustion air at seven different levels with the aim of attaining high combustion and low nitrogen oxides emissions. The plant’s weak gases are also incinerated as secondary air, which contributes to reduce odor from the plant. The boiler’s flue gases pass through electrostatic precipitators (ESPs) with four sections for the best flue gas separation, then the gases are cooled in a flue-gas cooler for production of warm water. The total length of the piping in the boiler body and connections in the boiler is 330 kilometers, with a total of about 8,500 welds. All welds were heat-treated before and after welding to eliminate unwanted tension in the material. Initially, the recovery boiler will be over-dimensioned. In addition, it is pre-designed for future expansion, which is accomplished by moving the left sidewall and by adding heating surface and a flue-gas section. The boiler is also equipped for feeding of sulfur and borate, if required. Design data Step 1 2 500 tds/24h 3 300 tds/24h Step 2 4 400 tds/24h 515 °C 105 bar(e) 383 t/h 144 °C 515 °C 105 bar(e) 703 t/h 144 °C 160 °C 160 °C 20 °C 25 °C Heavy black liquor Dry solids content Heating value 73 % 13,65 MJ/kgds 80 % Air of combustion 190 °C 190 °C 12,5 tds/24h/m2 1 990 kW/m2 11,3 m 13,5 m 152 m2 39 m 21,7 tds/24h/m2 3 440 kW/m2 15,0 m 13,5 m 202 m2 39 m Capacity, MCR excl. ashes *max capacity Steam and boiler feed water Steam temperature Steam pressure Steam flow, net Feed water tank temperature Feed water, temperature before economizer 1 Feed water, rise in temperature between economizers Furnace Black liquor load Width Depth Area, bottom of furnace Height to “nose arch” Tertiary Materials Primary ÖH (1A, 1B) Secondary ÖH (2) Tertiary ÖH (3) Quartenary ÖH (4) Qvintenary ÖH (5) Secondary Walls Bottom Primary 16Mo3 16Mo3 10CrMo910 10CrMo910 10CrMo910 X10CrMoVNb91 Sanicro 28 Compound Carbon steel Sanicro 38