Press folder

advertisement

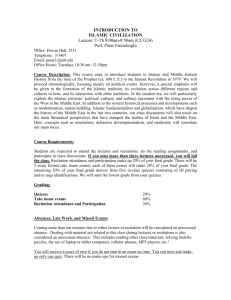

PRESS FOLDER ZOW BAD SALZUFLEN FEBRUARY 2010 PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 Your contact persons are: Ulrich Bühler Head of Sales/Marketing EGGER Group Klaus Monhoff Head of Product Management decorative EGGER Group PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 EGGER MASTERS A YEAR OF CHALLENGES In spite of initial difficulties, positive results were achieved in 2009, with added confidence for 2010 EGGER INVESTS IN DIGITAL PRINTING AT BRILON PLANT Virtual Design Studio (VDS) utilises this digital technology and allows the visualisation of new decors in virtual room sets CREATING CONTRASTS – HARMONIOUS OR EMOTIONAL At ZOW 2010, the wood-based material manufacturer EGGER presents new decors and a whole host of combination possibilities INTELLIGENT PRODUCT SOLUTIONS FOR THE FURNITURE INDUSTRY Compact laminate, EURODEKOR thin chipboard, thin chipboard support edging and an expanded acoustics programme represent EGGER’s new innovations for the furniture industry For queries: FRITZ EGGER GmbH & Co. Wood Based Panels Christina Werthner Weiberndorf 20 6380 St. Johann in Tyrol Austria P +43 5 0600-10681 F +43 5 0600-90681 christina.werthner@egger.com www.egger.com PLEON Publico Dr. Wolfgang Immerschitt Paracelsusstraße 4 5020 Salzburg Austria P +43 662 620 242-0 F +43 662 620 242-20 w.immerschitt@pleon-publico-sbg.at PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 EGGER MASTERS A YEAR OF CHALLENGES In spite of initial difficulties, positive results were achieved in 2009, with added confidence for 2010 The year 2009 presented never-before-seen challenges for the wood-based material manufacturer EGGER. Falling stock prices and liquidity shortages faced by banks not only plunged the financial system but the entire economy into a crisis. Ulrich Bühler, Head of Sales/Marketing EGGER Group, speaking at the traditional press reception prior to the ZOW in Bad Salzuflen, noted that this defined business developments. Yet he drew a positive conclusion: “In spite of difficult economic conditions, we achieved satisfactory results for the first six months of the current 2009/2010 business year. The markets have stabilised at a lower level.” The EGGER Group is pleased to report an overall stable financial position and strong equity ratio. Some far-reaching measures to reduce costs had to be implemented because of the crisis. These measures were effective and the international wood-based material manufacturer based in Austria ultimately weathered the difficult year of 2009 well. While turnover for the first six months (reporting date 31st October 2009) at EUR 741 million fell short of the same period last year (EUR 824 million), profitability is satisfactory thanks to cost reductions and lower raw material prices. The wood-based material manufacturer reported EBITDA (earnings before interest, taxes, depreciation and amortisation) of EUR 127.7 million for the first six months of the business year, an increase of 27 percent compared to EUR 100.3 million in the same period last year. NEW PROJECTS UNDER THE LONG-TERM STRATEGY This means EGGER can once again focus on the consistent implementation of its growth strategy. The key projects at this time are: The approval process for the resin plant in Radauti, which is progressing well. An administrative building for the Radauti plant in 2010, to be built almost entirely from EGGER materials. A recycling facility for the Barony plant. The extension of the ContiRoll in Brilon from 38 to 43 m (125 to 141 feet). Investing in a digital printing line for Brilon is also planned in order to further expand EGGER’s decor expertise. EGGER is planning investments totalling approximately EUR 60 million in the current business year. PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 CURRENT MARKET WEAKNESS OFFERS OPPORTUNITIES “Our decor and product expertise, our quality and our long-term, stable customer relationships allow us to gain market share,” explains Ulrich Bühler. Thanks to its plants distributed across Europe, EGGER is flexible in responding to fluctuating order volumes. The plants can help each other as needed. For example, this is the case during the pending conversion shut-down in Brilon so that customers do not suffer any disadvantages and full delivery capacity is maintained. The full impact of the crisis on the wood-based material industry is only being revealed gradually. Excess capacity will certainly be eliminated in Europe and especially in Germany along with restructuring. “Our advantage is that, in this situation, we can position ourselves even more effectively as a long-term, reliable partner for our customers,” Bühler concludes. OUTLOOK 2010 For 2010, EGGER believes that the worst of the market distortion is now behind us. However, the markets will remain at a low level for some time. The market outlook is therefore cautious yet confident overall: “We did our homework in good time. As a result, we are in a stronger position and filled with optimism as we head into 2010”. The company will adhere to its long-term strategy and, thanks to its modern plants and its innovative, comprehensive product range, expects overall developments during the remainder of the business year to be positive. EGGER is in a secure position, ready for further growth. FOCUS ON SUSTAINABILITY AND THE ENVIRONMENT Sustainability remains part of the practiced company philosophy in 2010 and continues to take centre stage. EGGER obtained a PEFC and FSC group certificate in January 2010. To date, the EGGER plants were certified individually. Now the company is able to produce FSC or PEFC-certified products at all EGGER plants – depending on wood availability – and thereby meet increased demand for certified goods among its customers. EGGER is currently constructing an administrative building in Radauti which will consist almost entirely of EGGER materials. All of the products have environmental product declarations; the company is striving to have the building certified. EGGER already demonstrated its focus on the environment and sustainability in 2009 – from environmental product declarations to the energy and environmental project in St. Johann, which has received several awards in the meantime. PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 EGGER RECEIVES AWARDS AS AN ENERGY-EFFICIENT COMPANY EGGER has received multiple awards for the energy and environmental project at the St. Johann plant. These include recognition as an “Energy-Efficient Operation” by the klima:aktiv programme and the Tyrolean Innovation Prize in the services category. In keeping with efforts made by EGGER to use wood for material and thermal applications, waste heat from the drying process is used to generate energy. EGGER supplies its entire wood-based material production facility in St. Johann and approximately 435 households in the community with environmentally friendly energy. This reduces CO2 emissions in the St. Johann valley by 28,000 tonnes per year. The environmentally-friendly logistics concept “EGGER – Logistics Systems with High Ecological Acceptance”, which EGGER has been continuously implementing since the year 2007, was also recognised by klima:aktiv. EGGER is promoting the conversion to environmentally-friendly vehicles and alternative drive systems with renewable energy. One of the most important objectives is to reduce truck traffic by switching to rail transport. The use of rail transportation was doubled over the last five years, thereby reducing CO2 emissions by 17.9 million tonnes. As a result, the company is eliminating the equivalent of 49,120 truck transports per year. REVIEW – OUTLOOK 2009: Positive results thanks to timely cost reduction measures 2010: Pursuit of higher market share in stabilised markets New investment projects in several plants Increased focus on sustainability and the environment PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 EGGER INVESTS IN DIGITAL PRINTING AT BRILON PLANT Virtual Design Studio (VDS) utilises this digital technology and allows the visualisation of new decors in virtual room sets As part of ZOW 2010, EGGER is presenting its activities in area of digital printing to the public for the first time. The wood-based material manufacturer intends to implement a self-contained digital printing process at the plant in Brilon (DE): from decor development and visualisation, all the way through to production. EGGER commenced initial activities in the field of digital printing at the beginning of 2010. Now these activities will gradually be expanded. The objective of this investment is to extend the decor range of the EGGER Group for melamine faced boards, laminates and laminate flooring with digitally created solutions. Plans are in place for the manufacture of recurring small production orders for the furniture industry and project-specific custom orders with a minimum quantity of 260 m² (2,799 square feet) using digital printing. To date, this type of production was not economically viable using conventional gravure printing lines. “With the help of digital solutions, we will be able to make our decor and service offerings to our customers much more individual and interactive in the future,” said Ulrich Bühler, Head of Sales/Marketing EGGER Group at the ZOW press conference in Bad Salzuflen. In order to develop know-how in this field, an investment in 2 workstations for the digital processing of artwork has been made at the Brilon plant. Another key investment will follow in May 2010. This is when a digital printing line for print base paper in a width of up to 2070 mm (81.50”) will complete the digital process. DESIGN STUDIO SUPPORTS VIRTUAL ROOM MODELLING With the Virtual Design Studio (VDS), EGGER will provide a “pioneering digital service”. It allows all digitally developed but not yet produced decors to be visualised in true colour and combined with other new or existing, implemented designs. In detail: “VDS HD” is a high-resolution programme that can be run on a highdefinition (HD) flat screen. This touch screen technology was developed by EGGER with a cooperative partner. Various room models can be interactively loaded from a room library on a 40 inch (102 cm diagonal measurement) screen and highresolution digital print decors can be applied. Zoom mode allows surface textures such as embossing or matt-gloss effects to be visualised down to the finest detail. With “VDS live”, EGGER also offers multi-projection visualisation. Decors are authentically represented one-to-one on a neutral-coloured furniture carcass. This allows the latest EGGERZUM decor innovations to be presented in a fascinating, impressively convincing quality using the “Kitchen” and “Office” applications. Decors PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 can be freely combined in keeping with the trade fair motto “Create Contrasts” to achieve the desired room design. EGGER will initially equip its showrooms in Brilon and St. Johann with the interactive visualisation tool following the ZOW. Installations for other plants and showrooms of the EGGER Group are already being planned. Based on the existing VDS technology, EGGER also intends to provide its customers with access to these digital processes. Customers can reap significant advantages from this vision which is already being implemented: Development and sampling processes of new developments are accelerated Participation in decor development becomes possible, leading to more individual design options The digitally developed decors can ultimately be presented in virtual rooms This leads to greater decision-making confidence with lower process costs. Another advantage: The effect of digitally developed decors can be simulated through the interplay with corresponding surface textures before actual samples are produced. DIGITAL PRINTING Investments in digital printing at the Brilon plant VDS offers additional customer advantages: accelerated development Self-contained digital printing process process, participation in decor development, visualisation in virtual Virtual Design Studio (VDS) as a rooms “pioneering digital service” VDS leads to greater decision-making confidence PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 CREATE CONTRASTS – HARMONIOUS OR EMOTIONAL At ZOW 2010, the wood-based material manufacturer EGGER presents new decors and a whole host of combination possibilities EGGER is picking up on an important trend of contrasting colours this year. Never before has furniture design been defined by contrasts as much as today. Following the black and white trend, playing and designing with contrasting colours and wood reproductions is the order of the day. Here the colour combinations range from harmonious to emotional. Next to “Create Contrasts”, last year's motto “Texture meets Colour” still remains valid. Klaus Monhoff, Head of Product Management decorative EGGER Group: “The decor textures remain an important foundation for the correct implementation in furniture design. Even more depth is emphasised in the new textures since more than touch is becoming important when it comes to surfaces. When used on uni colours in particular, the new motto is: you have to be able to “feel” surfaces with your eyes. UNI COLOURS IN THREE DIFFERENT COLOUR GROUPS In the coming year, the uni colours at EGGER will be classified into three different colour groups. The first group incorporates the sensuous, premium colours presented under the motto “luxurious warmth”. Colours such as Quartz Bronze, Quartz Saffron and the new Stone Grey dominate. They stand for warmth and opulence. Natural, elegant hues set the tone in the second colour group, accordingly presented as “natural elegance”. These include shades of grey with a proportion of green that tend towards the warmer range of the spectrum, yet simultaneously stand for elegance in spite of their naturalness. Slate Grey, Quartz Silk and Quartz Forest are among them. Last but not least, the third group contains the modern, cool tones. The term “contemporary cool” was selected for this group. Here the influence of contemporary architecture is readily apparent. This colour group encompasses Quartz Ice Silver, Quartz Indigo and Graphite Grey. There is no question that uni colours are ideal when playing with various levels of contrast and will be combined with each other even more so in the future. NATURE AS OUR MODEL Wood reproductions in many interpretations continue to play an important role. The current developments can be divided into two segments. On the one hand, EGGER is meeting market requirements by providing continuously adapted and optimised wood reproductions to its customers. One of the most perfect wood reproductions of recent years is the Avola Pine decor. Three new colour variations have been added to this decor, with was extremely successful last year. With the Aragon Oak and Venetian Cherry decors – each in three colour variations – natural hues are presented as well as more contemporary glazed colour variations. PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 Tauern Beech, a woodgrain from the past year, is also presented in two tones. The Vintage Oak, Core Ash and Mali Wenge decors mainly focus on presenting a “new naturalness”. On the other hand, two favourites of the EGGER design team - Ironwood and Ceramic Wood present two reproductions that do not focus on the natural characteristics of a certain type of wood. Here the overall effect of the decors takes centre stage. Ironwood emphasises the used look of wood, which can therefore be imitated in combination with modern materials or uni colours. Ceramic Wood is the reproduction of a fine linear ceramic look with wood characteristics; alternating streaks of colour create a lively contrast in this decor. WORKTOP DECORS FROM RESERVED TO LIVELY New worktop decors are also being presented. Here the palette ranges from rather reserved to more lively appearances. Tivoli, a calmer version of a travertine decor and Avalon, a mineral stone reproduction, fall into the reserved group. The terrazzo reproduction Bardolino and two different versions of marble reproductions with the decors Portoro and Lazio, both of which owe their liveliness to the design of the veins, are among the more lively options. Among the wood reproductions, the Arlington Oak decor was selected as a reproduction with an effect reminiscent of wide oak planks that is striking thanks to knots and other natural features. NEW TEXTURES EGGER is presenting new textures for both melamine faced products and worktops at the ZOW: Cottex is a textile texture that, in addition to its natural feel, exhibits matt gloss characteristics and therefore also creates an interesting effect on uni colours that can be perceived even from a distance. Perfect Pore features a low gloss level with especially deep, irregular oak pores. On uni colours in particular, Perfect Pore creates the effect of a painted wood surface. This texture creates the natural feel of solid wood for wood reproductions. Aluline is an even, finely brushed texture that gives any pearlescent decor the effect of a genuine aluminium surface. It also appears like smoothly brushed metal on uni colours or decors with polished metal characteristics. Argento creates a terrazzo effect on the worktop surface. Similar to small, joined stones, the texture exhibits good depth and is therefore ideal for stone reproductions but also on uni colours. Ceramic is suitable for worktop decors with a somewhat calmer, more elegant look. This texture features an irregular but flat substructure covered in small gloss highlights. This gives Cristalstone the sparkling character of small crystals. PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 CREATE CONTRASTS Contrasts: harmonious to emotional Wood reproductions: Ironwood and colour combinations Ceramic Wood are the favourites of the EGGER design team Touch: all of the new textures exhibit significantly more depth Uni colours: grouped into three different colour groups Worktop decors: from reserved to lively Five new textures: Cottex, Perfect Pore, Aluline, Argento, Ceramic PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 INTELLIGENT PRODUCT FURNITURE INDUSTRY SOLUTIONS FOR THE Compact laminate, EURODEKOR thin chipboard, thin chipboard support edging and an expanded acoustics programme represent EGGER’s new innovations for the furniture industry A complete product system is the EGGER motto. Harmonised selections of trend-conforming decors and surfaces with the corresponding coreboards are available for all areas of application. This year EGGER presents new core products such as compact laminate and EURODEKOR thin chipboard at ZOW 2010 along with innovative accessories such as thin chipboard support edging. The expanded acoustics programme constitutes another focal point of the trade fair. All of the latest EGGER products are also presented in a new brochure. “Products 2009-2010” which shows all coreboards as well as accessories. The individual products are presented in a clear layout – from raw chipboards to laminated EURODEKOR boards and laminates to edging solutions. In addition, a table shows their availability from the 15 EGGER plants. COMPACT LAMINATE FOR INTERIOR APPLICATIONS EGGER has been offering compact laminate for the furniture industry since September 2009. Effective immediately, it is also available in the quality flammex Euroclass B (low flammability) in accordance with DIN EN 438-4:2005 type CGF (Compact General-purpose Flame-retardant). EGGER compact laminate flammex Euroclass B meets the special requirements of DIN EN 13501-1 in case of fire. According to DIN EN 13501-1:2007, it is classified as follows: reaction to fire B, smoke development s2, dripping/dropping while burning d0. The compact laminate generally features a multilayer composition and consists of melamine faced decorative papers and several core layers impregnated with phenolic resin. With a thickness range from 5 to 13 mm (0.20 to 0.51”), it is especially suitable for classic interior applications such as tables, work surfaces and wall cladding. “Especially in the furniture industry, we see great potential for thin, easy-care boards with a durable surface,” explains Ulrich Bühler, Head of Marketing/Sales EGGER Group. The board is available with any decor. ACOUSTICS PROGRAMME OPENS NEW HORIZONS EGGER has extended its acoustics programme with a greater variety of decorative and economical solutions. Even more individual design possibilities are now offered. In addition to a much larger selection of perforation patterns, which now also include slotting, all of the decor and material combinations of the EGGER ZOOM collection PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 are available as well. EURODEKOR melamine faced chipboard and MDF with dimensions of up to 3,500 x 2,070 mm (137.80 x 81.50”) are available as standard. The ProAcoustic boards feature high sound absorption and can be used as wall and ceiling solutions or, with a laminated decor on both sides, for furniture construction. The ProAcoustic light series has now been expanded with furniture boards and back panels. At the St. Johann forum and in Brilon, interested parties can experience the sound-absorbing effect of the ProAcoustic boards for themselves. This is where the “Acoustic Box” is set up. It consists of two individual boxes, one with and the other without ProAcoustic. This provides an impressive demonstration of the sound absorption effects of different materials. DECORATIVE THIN CHIPBOARD FOR THE DOOR INDUSTRY Especially for the door industry, EGGER has brought a melamine faced EURODEKOR thin chipboard to market. This board is also suitable for further processing and may serve as an integrated component of sandwich boards. EGGER thin chipboard is available in numerous EGGER decors and textures from a thickness of just 3 mm. Thanks to its scratch resistance, resistance to abrasion and resistance to chemicals, the surface is considerably more robust than the previously used films. The core of the product is the EGGER thin chipboard, a lightweight high density board with a low bark proportion and especially fine and quiet chip structure. Due to its increased raw density, it conforms to the criteria of the RAL quality control association for interior doors and meets the special requirements for impact resistance and mechanical resistance. THIN CHIPBOARD SUPPORT EDGING FOR LIGHTWEIGHT BOARDS Thin chipboard support edging is an innovative solution for edging lightweight boards. It can be used in a range of widths from 10 to 100 mm and is suitable for problem-free machine processing. “In order to meet the high demands in processing all kinds of lightweight boards, especially frameless lightweight boards, we had to come up with a special solution,” says Ulrich Bühler in describing the new product. The thin chipboard support edging braces the surface layers of the lightweight board against each other along the edge. Therefore, smooth machine processing can also be assured for frameless lightweight boards with surface layers of less than 8 mm. PRESS FOLDER ZOW BAD SALZUFLEN, FEBRUARY 2010 THE LATEST PRODUCTS “Products 2009-2010” brochure contains all coreboards Compact laminate with a multilayer composition for classic interior applications, also in a fire-resistant quality rear panels and new perforation patterns EGGER thin chipboard is available with all EURODEKOR decors and is mainly used for doors Thin chipboard support edging for edging EUROLIGHT boards with surface layers Expanded acoustics programme with of less than 8mm ProAcoustic lightweight furniture boards,