Dyson Vacuum Cleaner: History and Innovation

advertisement

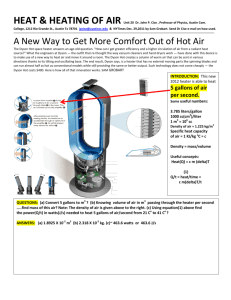

The Dyson Vacuum Cleaner The bag problem In 1978, while vacuuming his home, James Dyson realized his bag vacuum cleaner was constantly losing suction power. He noticed how dust quickly clogged the pores of the bag and blocked the airflow, so that suction dropped rapidly. He set to work to solve this problem. 5 years and 5,127 prototypes later, the world's first cyclonic bagless vacuum cleaner arrived. No place for new technology James Dyson offered his invention to major manufacturers. One by one they turned him down, apparently not interested in new technology. They seemed determined to continue selling bags, worth $500 million every year. Later, Hoover's Vice President for Europe, Mike Rutter, said on UK national TV: "I do regret that Hoover as a company did not take the product technology off Dyson; it would have lain on the shelf and not been used". The first Dyson So James Dyson decided to manufacture his own vacuum cleaner. In June 1993 he opened a research centre and factory near his home in England to begin making his machine. It even collected the finest particles of dust (microscopic particles as small as cigarette smoke) without clogging. The result was the Dyson Cyclone, the first vacuum cleaner that didn't lose suction. Something to hide In under 2 years, Dyson was the UK's best-selling vacuum. Miele, Bosch, Siemens, Electrolux and Philips tried to stop Dyson showing how their models clogged and lost suction. Later, manufacturers started to admit that bags reduced suction, and then tried to jump on the bandwagon to produce `bagless' vacuums, but these also clogged just like a bag vacuum. Meanwhile 60% of people were buying a Dyson because it was recommended to them. More cyclones The original team of 3 Dyson engineers grew to 350 scientists in a new research centre, investigating ways to make products work better. Determined to create vacuums with even higher suction, the cyclonics team set to work developing an entirely new type of cyclone system. They discovered that spreading higher airflow through many cyclones generated even higher suction power, which picked up more dust from the floor. Hence the Root8Cyclone™ was created. The patent nightmare James Dyson's vacuum was nearly never made due to patent fees and legal costs incurred defending his invention against patent infringement by a giant corporation. During the development years when James had no income, this nearly bankrupted him. He risked everything, and fortunately the risk paid off. Then in 1999, Hoover UK tried to imitate a Dyson and James was forced back to court to protect his invention again. After 18 months Dyson finally won a victory against Hoover UK for patent infringement. Another problem to solve "I like your vacuum cleaners but when will you make one you don't have to push around?" This casual remark set James Dyson's mind working. Producing something that bounced off furniture and picked up very little dust would have been easy, but James Dyson insisted his robot should not only clean well but also guide itself more logically than a human would. So Dyson designed a robot with 3 on-board computers and 50 sensory devices to navigate itself around a house and clean properly. Two drum, not humdrum When Dyson re-examined the washing machine, they were astonished to discover that 15 minutes of handwashing washed clothes cleaner than 67 minutes in a best-performing washing machine. So Dyson set about replicating a hand wash action to manipulate and flex fabric to release dirt more quickly. The result was the Contrarotator™, the world's first washing machine with 2 drums. Suddenly you could wash clothes faster and more gently, and with cleaner results.