James Dyson Biography & Vacuum Cleaner Design

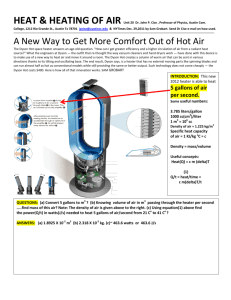

advertisement

School Improvement Service A GTCW project This presentation was produced by Mr Chris Harper St Julian’s School Newport As part of a GTCW network project We would like to thank James Dyson for his cooperation with this project School Improvement Service A GTCW project dyson JAMES BIOGRAPHY OF JAMES DYSON EARLY PRODUCTS OF JAMES DYSON PROBLEMS WITH TRADITIONAL VACUUM CLEANERS THE DESIGN AND DEVELOPING PROCESS THE DYSON DUAL CYCLONE INTELLECTUAL PROPERTY THE DYSON CONTRAROTATOR THE DYSON PRODUCT RANGE School Improvement Service A GTCW project BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES This presentation tells the remarkable story of how James Dyson took on the manufacturing giants to reinvent the domestic vacuum cleaner and build a successful business making and selling his revolutionary design. BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES James Dyson has a successful track record as an inventor and developer of innovative products. Yet he struggled for years to win the financial backing for his new vacuum cleaner. BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES The development of James Dyson’s world-beating Dual Cyclone vacuum cleaner is a British success story. It unites design, innovation, technology and entrepreneurship around a single personality in a way which is perhaps unique. BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES James Dyson’s company has emerged to establish itself as the premier league of British manufacturers. The company has designed, produced and marketed Britain’s top-selling upright and cylinder vacuum cleaners. In the process it has become a £100 million company, the UK’s fastest growing manufacturer. BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES Its products are not sold on price, indeed they are more expensive than their rivals. What makes Dyson Dual Cyclone so distinctive is its adoption of an entirely new technology and its commitment to design as a way to gain competitive advantage. BIOGRAPHY OF JAMES DYSON School Improvement Service A GTCW project BIOGRAPHY OF JAMES DYSON dyson JAMES People argued that if his idea really worked, the big manufacturers would already have developed it. Others said that, as a designer he knew nothing about business and marketing. No development agency would touch the Dual Cyclone. James Dyson was prepared to prove them all wrong. School Improvement Service A GTCW project EARLY PRODUCTS OF JAMES DYSON School Improvement Service A GTCW project dyson JAMES Such determination was evident from very early in his career. While studying at the Royal College of Art in the late 1960’s he began working with the engineer and inventor Jeremy Fry on the development of a Seatruck EARLY PRODUCTS BY JAMES DYSON School Improvement Service A GTCW project dyson JAMES His first invention was the ball barrow. This became a market leader in the wheelbarrow sector within three years. The Waterolla plastic garden roller and the trolleyball boat laucher followed. THE dyson BALLBARROW School Improvement Service A GTCW project dyson JAMES This is the only boat trolley capable of floating. The design doesn’t disappear beneath the water or sink in the sand, it is much easier to slide into position under the boat. The webbing fits any shape of hull without any risk of damage. THE dyson TROLLEYBALL School Improvement Service A GTCW project dyson JAMES The Seatruck was a high speed marine vehicle for military, oil and construction industries, which earned sales worth $750 million in more than 50 countries. The Seatruck was the beginning of a string of Dyson successes. THE SEATRUCK DESIGN School Improvement Service A GTCW project PROBLEMS WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES In 1978 James Dyson first realised the problem with bag vacuum cleaners: they clog and loose suction. He had the idea for a vacuum cleaner that used a cyclone instead of a bag and did not loose suction. 15 years and 5127 prototypes later, having been turned down by all the big appliance manufacturers, he launched the Dyson DC01. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES Over a year, the average home accumulates enough dust to fill a bathtub. This dust contains among other things, decaying human skin, dust mites, pet hairs and allergenic particles. Vacuuming with a conventional vacuum cleaner fails to remove all this detritus. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES Every design project starts with dissatisfaction with what already exists. James Dyson’s mission was to improve on the clogged bag of the domestic vacuum cleaner, whose basic design principles had been unchanged for nearly a century. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES Dyson was frustrated because his own experiences told him that conventional bag vacuum cleaners failed to produce enough suction to remove dust properly. Dust is a big problem, it is full of allergenic particles which are harmful to children and people with respiratory problems THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES Dyson recognised that the reduction in a vacuum cleaners suction wasn’t due to the volume of dust in the bag, but to the fact that fine dust particles quickly clog the pores of the bag and blocks the airflow. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES After cleaning with a conventional vacuum cleaner, all of the air in the room has been filtered through pet hairs and dead human skin to produce a recognisably unpleasant aroma. The bags themselves can be a problem both to fit and to obtain. They can also dislodge and tear in the machine. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project dyson JAMES Most of us have complained about these problems for years but have simply regarded them as problems inherent to vacuum cleaning. Dyson however actually decided to do something about it. He began to develop a radical alternative – the world’s first bagless vacuum cleaner. THE PROBLEM WITH TRADITIONAL VACUUM CLEANERS School Improvement Service A GTCW project THE DESIGN AND DEVELOPING PROCESS School Improvement Service A GTCW project dyson JAMES When designing a new vacuum cleaner, engineers began by writing a brief, based on their own ideas and suggestions from users of previous vacuum cleaners. When they began work on the cylinder vacuum cleaner (DC02) they wanted to develop a smaller, lighter, quieter and more powerful vacuum cleaner. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES This was partly a response to the need to develop a cylinder cleaner for new international markets such as Japan, as well as existing markets in Europe. Dyson also felt that such a machine would be very well received by older people who wanted a powerful and lighter machine, or people who had limited storage space. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES Engineers at Dyson started generating concepts by quickly producing a large number of sketches in response to the brief. This produces a wide range of ideas; for example the stair hugging shape of the DC02 and DC05. A detailed specification was written which set out all the key design features. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES Balancing ideas about function, safety, reliability, aesthetics and cost is a complex process. Should any of these aspects change for any reason the whole design could be affected. During the design process, engineers make hundreds of different prototypes. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES Models and prototypes are an excellent way of testing ideas and getting a good impression of how the product might work and look. Using a variety of types of prototypes such as CARDBOARD ( to help break the product down into components ) THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES BLUE FOAM ( to help develop form and ergonomics ) BREADBOARD MODELS ( to give an idea of how the design would perform and fuse deposition modelling (FDM) in conjunction with sketches and CAD to test the idea against the original specification. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES Feedback from the prototypes used THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES INJECTION MOULDING Polymer ( a type of plastic ) is added to the hopper (A) The hopper continually feeds a rotating screw which is contained within a heated barrel. The screw injects the heat melted polymer into a mould cavity ( B ) After it has cooled and set to the shape it is then ejected ( C ) THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES Injection moulding is the most common moulding process used by the plastics industry. The process is extensively used for thermoplastics. They soften on heating, harden on cooling and so can be repeatedly processed. This process is used for mass production and is capable of producing very large numbers of identical complex mouldings. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES QUALITY CONTROL When a component has been manufactured you should look to see that there is as little evidence as possible of the manufacturing process. Visible imperfections detract from the quality of the product. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project dyson JAMES The following are all imperfections sometimes found on injection moulded parts: FLASH – wafer thin material where the two halves of the mould join SPLIT LINE – a fine line where the two halves of the mould join FEED POINT – this mark is where the material flowed into the mould SINKAGE – uneven surfaces usually found above a rib DISTORTION – a large area of the part is twisted or bowed. THE DESIGN AND DEVELOPMENT PROCESS School Improvement Service A GTCW project THE DYSON DUALCYCLONE School Improvement Service A GTCW project dyson JAMES Anyone who has seen a picture of a tornado can imagine its astonishing power. Everything in the path of the twisting air is sucked up. The Dual Cyclone follows the same principle but on a smaller scale, and with the help of a 1300 watt electrical motor Dirt-laden air is sucked up into the vacuum cleaner THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES The air enters the outer cyclone chamber at a tangent. The air spirals downwards, accelerating to 200mph, creating sufficient centrifugal force to throw the larger debris against the walls of the bin. THE dyson DUAL CYCLONE School Improvement Service A GTCW project THE dyson DUAL CYCLONE dyson JAMES Within the outer cyclone lies the inner chamber. The air enters via the shroud at the top, which only allows the finer particles of dust to pass through. This air spins faster as it twists down the inner cyclone funnel. The air reaches a speed of 924mph. That’s faster than the speed of sound !! School Improvement Service A GTCW project dyson JAMES The centrifugal force created within the inner cyclone forces even the tiniest particles of dust to spin out. Not even cigarette smoke can escape. THE dyson DUAL CYCLONE When the air leaves the vacuum cleaner, it is cleaner than the existing air within the room and odourless. School Improvement Service A GTCW project dyson JAMES The Dyson DC07 uses the most advanced cyclone technology to maintain the highest constant suction. The Dyson root cyclone not only gives constant suction but has 45% more suction than the dual cyclone. Engineers at Dyson reduced the diameter of each cyclone to help the vacuum cleaner to pick up more dust. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES The cone shaped cyclone speeds up the spinning air to create greater centrifugal force This throws the very fine dust particles out of the air. Dyson realised that by spreading the high volume of air simultaneously through many cyclones gave higher suction power than previous models. THE dyson DUAL CYCLONE School Improvement Service A GTCW project INTELLECTUAL PROPERTY School Improvement Service A GTCW project dyson JAMES No aspect of a new product is safe from copying without a patent. Before the first Dyson vacuum cleaner was launched James Dyson spent £700,000 on worldwide patents to protect his invention. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES Today there are more than 100 registered patents in the name of Dyson. Inadequate patent protection means that competitors are likely to come along and take your idea. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES James Dyson found out how important it is to have sufficient legal protection when his concept for an integral telescopic hose, which was one feature on the DC01 was not properly protected by his patent attorney and is now used on most upright vacuum cleaners. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES Dyson also fought and won a nerve wracking five year battle against a giant American corporation to bring his idea to market. His US rival had copied his idea and guessed wrongly, that Dyson would have neither the resources nor the will to pursue the matter through the courts. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES Having won the court case Dyson was then free to focus on manufacturing in the UK. He had been careful to retain full control of his invention this time because he had previously sold shares in his ballbarrow to raise cash and found himself a minority shareholder. THE dyson DUAL CYCLONE School Improvement Service A GTCW project dyson JAMES On the Dyson Dual Cyclone Project he was able to maintain total control over the design development. “Never ever assign a patent or sell yourself cheaply – because creativity is a rare commodity. Designers are particularly bad at knowing their own worth” James Dyson THE dyson DUAL CYCLONE School Improvement Service A GTCW project THE DYSON CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES James Dyson has also developed a new washing machine. He asked his engineers to experiment with every imaginable way of washing: with and without detergent; with detergent but without movement; without water and even by hand to find out what was wrong with existing washing machines. THE dyson CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES Dyson discovered that washing garments by hand produced better results than single drum machines. He found that the clothes were constantly on the move, they are manipulated and flexed. Washing clothes by hand opens the weave of the fabric and agitates the dirt more to release it easily and quickly THE dyson CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES The single drum can only go round in one direction at a time, taking the clothes with it. On each circuit the clothes drop and flop to the bottom of the drum. Without much movement Dyson discovered that the clothes tended to tangle or bundle. With so little wash action the clothes need an extended soak in the detergent. THE dyson CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES To replicate the movement by hand, Dyson engineers designed two aligned rums and engineered them to rotate in opposite directions at the same time. The clothes are much more active moving in an infinitely variable dance to flex the fabric and open the weave to the detergent. THE dyson CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES The larger Dyson drums allow clothes to spread out evenly so that the water does not have to escape through such a thick layer of clothes. Therefore less drying time is needed after the wash. THE dyson CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES The Dyson has a deeper double drum with a larger circumference. This creates greater centrifugal force for less revolutions, which means that only 1400 spin speed is needed to get the clothes dry. The Dyson drums also have more perforations to allow the water to escape faster. THE dyson CONTRAROTATOR School Improvement Service A GTCW project THE dyson CONTRAROTATOR dyson JAMES A single drum has a thick rubber seal which holds the drum to the cabinet. As the drum moves while the machine is in use, the seal has to stretch and compress This rubber seal found on conventional machines collects dirt and you have to pull your clothes over the seal to remove them from the machine. School Improvement Service A GTCW project dyson JAMES It can also be difficult loading and unloading clothes using conventional machines. If the seal twists out of shape, water can leak from the machine. The diagrams on the left show Dyson’s large rubber bellows and smooth plastic lip which has replaced the rubber seal THE dyson CONTRAROTATOR School Improvement Service A GTCW project DYSON PRODUCT RANGE School Improvement Service A GTCW project THE DYSON – DC01 THE DYSON – DC02 THE DYSON – DC03 THE DYSON – DC05 THE DYSON – DC07 THE DYSON – CONTROROTATOR School Improvement Service A GTCW project THE DYSON - DC01 School Improvement Service A GTCW project dyson JAMES SAFETY VALVE No suction is present at the end of the hose until the wand is unclipped. TELESCOPIC HOSE When you press the yellow catch the hose is ready to use. CLEANING STAIRS When the catch is released the hose can be stretched to 13ft. This total length can reach the top of the average staircase. FEATURES OF THE DC01 School Improvement Service A GTCW project dyson JAMES EASE OF USE At 45 degrees, the natural angle for cleaning, the machine is perfectly balanced. MATERIALS The body of the Dyson Dual Cyclone is made from ABS and Polycarbonate. INTEGRAL TOOLS All Dyson cleaning tools are always at hand. FEATURES OF THE DC01 School Improvement Service A GTCW project dyson JAMES EASY TO TURN The large wheels have been designed to make the Dyson turn easier with no scuffing. STABLE DESIGN The hose is connected to the base of the machine. This means that when pulled along by the hose, the machine will follow and not fall down. FEATURES OF THE DC01 School Improvement Service A GTCW project dyson JAMES SELF ADJUSTING HEAD When moving from carpet to a smooth floor, the height of the cleaner head adjusts automatically. TRIPLE ROW BRUSH BAR The Dyson Dual Cyclone is the only vacuum cleaner to have three rows of brushes. This provides more effective brushing. FEATURES OF THE DC01 School Improvement Service A GTCW project FEATURES OF THE DC01 dyson JAMES TRANSPARENT BIN This has three advantages: you can see how well the Dyson has worked; you can enjoy watching it and you can always tell when its full NO BAG ODOUR Original bag vacuum cleaners will blow any smells from the bag out into the air. In the Dyson the particles are trapped away from the airflow. School Improvement Service A GTCW project THE DYSON – DC02 School Improvement Service A GTCW project dyson JAMES EASE OF USE The Dyson DC02 is the only vacuum cleaner that is designed to sit on the stairs. Other vacuum cleaners are notoriously unstable when you vacuum the stairs. LIGHT TO CARRY The DC02 weighs only 6.3kg which makes it easier to carry around the home. FEATURES OF THE DC02 School Improvement Service A GTCW project dyson JAMES CARTRIDGE FILTERS The electrostatic H-Level cartridge filters on the Dyson give a total filter area of over 756 square centimetres INTEGRAL TOOLS All the Dyson cleaning tools are always close at hand in their special compartment. FEATURES OF THE DC02 School Improvement Service A GTCW project FEATURES OF THE DC02 dyson JAMES EASY TO MANOEUVRE The large rear wheels and the small front castor design make it easy to manoeuvre around corners and over different levels. FAN/MOTOR DESIGN Dyson has incorporated a multi-bladed curved turbine fan which allows the motor to produce incredible power for its size. School Improvement Service A GTCW project dyson JAMES SUCTION RELEASE TRIGGER Dyson’s unique ergonomically designed handle comes with a conventional placed suction release trigger. This means that you can control the suction without having to adjust a dial on the cleaner. FEATURES OF THE DC02 School Improvement Service A GTCW project THE DYSON – DC03 School Improvement Service A GTCW project FEATURES OF THE DC03 dyson JAMES FILTRATION SYSTEM The DC03 has two HEPA filters FILTER 1 The pre motor filter has a Bactiguard screen which captures minute particles and kills harmful bacteria FILTER 2 This filter traps particles as small as 0.1 micron and harmful carbon emissions from the motor. School Improvement Service A GTCW project FEATURES OF THE DC03 dyson JAMES ADAPTIVE BRUSH CONTROL This device allows the cleaning of hard floors by switching off the brushbar. The safety alert function makes a ratchet noise to warn of any obstruction. QUICK RELEASE WINDOW Using a coin the clear window can be removed and any obstruction can be removed. School Improvement Service A GTCW project dyson JAMES ADAPTIVE SOLEPLATE GEOMETRY This soleplate pivots to maintain contact with the carpet, whether the cleaner is moving forwards or backwards. BLOCKAGE REMOVAL CASSETTE This cassette allows easy access to the base of the duct and hose. FEATURES OF THE DC03 School Improvement Service A GTCW project THE DYSON – DC05 School Improvement Service A GTCW project dyson JAMES INTUITIVE CONTROLS Designed to work with cleaning habits, the on/off pedal is operated from the front of the machine, where you clean while the cord rewind pedal is activated from the back where you unplug the cable. FEATURES OF THE DYSON DC05 School Improvement Service A GTCW project dyson JAMES ERGONOMIC WAND ASSEMBLY The ergonomicallydesigned assembly rotates 360 degrees to reduce strain on the user’s wrist. ADJUSTABLE WAND The ratchet action wand telescopes to the length that you want. Grip the sleeve and pull. FEATURES OF THE DYSON DC05 School Improvement Service A GTCW project dyson JAMES DYSON DESIGNED FLOOR TOOL This tool adjusts to be more effective on hard floors and carpets and maintains perfect contact with the floor CARPET BRUSHING With the brush bar powered by constant airflow, the optional turbo brush improves the pick up of dust. FEATURES OF THE DYSON DC05 School Improvement Service A GTCW project THE DYSON – DC07 School Improvement Service A GTCW project dyson JAMES REMOTE TRIGGER BIN EMPTYING The trigger in the dc07’s carry handle releases a trapdoor in the clear bin, so you can empty the dust quickly. INTERNAL BIN BAFFLES Radial fins in the outer cyclone forces the dust to settle in the bottom. FEATURES OF DC07 School Improvement Service A GTCW project dyson JAMES EDGE CLEANING WHISKERS DC07’s suction is channelled right to the edges of the cleaning head. Its protruding whiskers, angled to reach down between the skirting board and the floor can flick dust directly into the airflow. FEATURES OF DC07 School Improvement Service A GTCW project dyson JAMES AUTOMATIC SUCTION CHANGE OVER. In the upright position the DC07’s suction is automatically directed through the hose. BRUSH CONTROL The Dyson’s unique brush control system allows you to switch off the brush bar when vacuuming delicate flooring. FEATURES OF DC07 School Improvement Service A GTCW project THE DYSON - CONTROROTATOR School Improvement Service A GTCW project dyson JAMES EASY OPEN SOAP TRAY Just push to open and push to close. Removes easily to clean under a tap. PADDLE DESIGN This enhances the wash action by increasing fabric movement. FEATURES OF THE CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES ROLLER-JACK HANDLE The retracting roller-jack handle pulls out to manoeuvre the machine easily. TRANSPARENT COIN TRAP Trapped coins and buttons and also gives easy access to the filter. FEATURES OF THE CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES HYGIENIC LONG LIFE SEAL This seal doesn’t trap slime, smell or damage clothes. KING SIZE DUVET WASH The machine has a 78 litre capacity which is 60% larger than its competitors. FEATURES OF THE CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES DOUBLE DOORS This gives extra security. The doors lock when the drums are moving and release as soon as the cycle has finished. TOUGHENED CLEAR DOOR The door is made from the same polycarbonate material as crash helmets. FEATURES OF THE CONTRAROTATOR School Improvement Service A GTCW project dyson JAMES FEATURES OF THE CONTRAROTATOR