DOC

advertisement

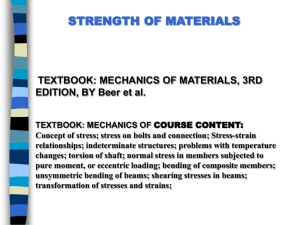

MEC 1205: Mechanics of Materials I Hours per Semester Weighted Total Mark Weighted Exam Mark Weighted Continuous Credit Assessment Mark Units LH PH TH CH WTM WEM WCM CU 45 30 60 100 60 40 4 75 Course Description This course deals with the behavior of solid bodies subjected to loads. It is to enable the student understand the way in which solid bodies behave under action of forces, the deflections that result and the stresses and strains set up in these bodies. It is to help the student in the design of mechanical components such as beams, cylinders, shafts, struts. Objectives The objectives of this course are to teach the student: • • • • • The basic theory of stress and strain Solutions of direct and shear stresses on machine components Analysis of simple beam stresses Analysis of torsion of shafts Derivation of stress-strain constants from test diagrams Learning outcomes At the end of the course, the student shall be able To evaluate stress and strain values for objects or systems under various loading conditions and apply these concepts in the solution of problems involving thin cylinders, spherical shells and simple structures To use simple bending theory to analyse systems under complex loading conditions such as eccentric loading and skew loading Use the knowledge acquired in this course to design various mechanical systems and subsystems for various loading conditions. Detailed Course Content 1. Principles of Stress and Strain • Tensile stress and strains • Hooke's law • Tensile test • Poisson's ratio • Shear stress, stress on compound bars • Thin cylinders, spherical shells • Thermal stresses 2. Bending stresses • Simple bending theory (5 Marks) (6 Hours) 3. 4. 5. 6. 7. 8. • Bending stress distribution, Section Modulus • Composite flitched beams • Skew loading • Combined bending and direct stress Shear stresses in beams (7 Hours) • Distribution of shear stress due to bending in rectangular sections, I-sections, T- sections, and circular sections • Application to composite sections Torsion (8 Hours) • Torsion theory, Modulus of section, Tensional rigidity • Torsion tests • Torsion of composite shafts • Torsion of a tapering shaft • Power transmission • Shear strain energy Complex stresses (7 Marks) • Stresses on Oblique planes (shear and direct stresses) • Principal stresses and principal planes, maximum shear stress • Mohr's stress circle • Combined bending and twisting • Combined thrust, twisting and bending Complex strains and elastic constants (6 Marks) • Strains for tri-axial stress state • Principal strains interns of stresses • Bulk Modulus, volumetric strains, lateral restraint, • Relationship between Elastic Constants Theories of Failure (6 Hours) • Maximum principal stress theory (Rankine) • Maximum shear stress theory (Guest - Tresca) • Maximum principal strain theory (Saint - Venant) • Total strain energy per unit volume (Haigh) • Shear strain energy per unit volume (Maxwell - Huber -von Mises Laboratories (30 hours) • • Tensile test and Torsion Test in the Materials testing Laboratory Mode of Delivery The course will be taught by using lectures, tutorials, assignments and practical thermodynamics laboratory sessions. Mode of Assessment This shall be by practicals, assignments, tests and examination. The relative contribution to the final grade will be as shown below: Assessment Contribution Tests / Assignments/ Practicals 40% Final Examinations 60% Total 100% Reference Text Books G.H Ryder, 1969. Strength of Material, Student International Edition, Palgrave Macmillan. R. C. Stephens, 1970. Strength of Materials: S.I. Units: Theories and Examples D. H. Bacon and R. C. Stephens, 1999. Machine Technology, 3rd Edition. Industrial Press Inc E. J. Hearn, 1997. Mechanics of Materials I, an Introduction to the Mechanics and Elastic and Plastic Deformation of Solids and Structural Materials, 3rd edition, University of Warwick, United Kingdom. A.C Ugural, 1991, Mechanics of Materials, McGraw-Hill, Inc

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)

![Strength of Materials [Opens in New Window]](http://s2.studylib.net/store/data/009980952_1-af573ee3f319ca71dbd5b53d99fdf436-300x300.png)