Question 1

advertisement

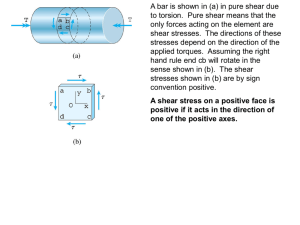

PD4 Mechanics 2005 Summer Question 1 Part a: A compound bar consists of a brass tube 60mm outside diameter and 48mm inside diameter and length 100mm surrounding a solid steel bar of 45mm diameter of the same length. Calculate the stresses and strains induced in both materials when subjected to an externally applied load or 150kN. [14] 2 Esteel = 200GN/m Ebrass = 100GN/m2 Part b: Determine also the change in length of the assembly. [3] Part c: In order to reduce the amount of material used. The diameter of the steel section is to be reduced. Determine the minimum diameter of steel section if the maximum stress is limited to 100MN/m2. [3] Question 2 numbers below beam represent distances in metres from left hand edge The beam shown has a length of 8m and is simply supported at positions A and D. The beam is loaded by concentrated loads of 4Kn, 6kN and 2kN respectively and carries a distributed load of 2 kN/m, between B and C. Determine the reactions at the supports. Determine the shear force at each lettered location in the beam (and intermediate locations if required) and draw a shear force diagram. Determine the bending moment at each lettered location in the beam (and intermediate locations if required) and draw a bending moment diagram. Determine the absolute maximum bending moment Determine the exact location of the point of contra-flexure [2] [6] [6] [2] [4] PD4 Mechanics 2005 Summer Question 3 The diagram opposite shows the loading conditions for a 40mm diameter steel shaft E = 200 GN/m2. The shaft is supported in bearings at 0mm and 370mm respectively (and can be considered as simply supported). It carries loads of 130, 140 and 150N. Part a: Using McCauley’s method, derive expressions for the slope and deflection of the beam under the specified loading conditions. N.B. Shaft stationary [14] Part b: Calculate the magnitude and direction of the deflection under each of the applied loads. [6] Question 4 Part a A hollow steel drive shaft, 200mm OD and 100mm ID and 2 metres long, is used to transmit 694KW while rotating at a speed of 90 RPM. Determine: 1. the maximum shear stress in the material and 2. the angular twist in degrees. [G = 80 GN/m2] [12] Part b It is required to replace the drive shaft due to wear and hollow stock is not available. If a solid steel shaft is to be used instead to transmit the same power at the same speed, calculate the diameter, which would be required if the shear stress is not to exceed that calculated in part a. [4] Part c Determine the percentage change in both the weight and then angle of twist using the replacement shaft. [4] PD4 Mechanics 2005 Summer Question 5 A material element is subjected to a horizontal tensile stress of 60 MN/m2 and a vertical tensile stress of 80MN/m2, together with a shear stress of 50MN/m2, those on the 60MN/m2 planes being counter clockwise in direction. Part a: Determine: 1. The normal and shear stresses on the 45 plane shown 2. The principal stresses and their angles to the X axis 3. The maximum shear stress in the material. [6] [6] [4] Part b If the applied shear stress xy (currently 50) where to be increased, what would be the maximum allowable value of xy if the maximum principal [4] stress is not to exceed 150MN/m2. Question 6 Part a: Explain why strain gauges are sensitive to strain along the direction in which they are placed, yet are not sensitive to strain across the gauge. [4] Part b: In order to determine the stresses in a pressure vessel a 0-45-90 degree strain gauge rosette is applied randomly to the pressure vessel. The values registered by the strain gauges are as follows. Gauge A = 400 x 10-6 Gauge B = 350 x 10-6 Gauge C = 125 x 10-6 Determine graphically or analytically the principal strains in the material. Part c: As the object is a pressure vessel, comment on the expected results from the stress calculation and then calculate the values of the maximum and minimum principal stresses in the material. E=200MN/m2 , v = 0.3 Part d: Calculate the angles of the principal strains and in turn demonstrate the help of a sketch the orientation of the ‘randomly placed’ strain gauge to the axis of the pressure vessel. [8] [4] [4] PD4 Mechanics 2005 Summer Mechanics Formulas Bending in Beams M E I y R Parallel axis theorem. I Io Ah 2 Composite shafts Shafts in series Shafts in parallel: I = d4 64 I = bd3 12 Torsion in shafts T G J R L Figure 1: Second moment of Area a b Ta Tb T Ta Tb a b J= d4 32 Figure 2: Polar Second moment of Area Slope and deflection of beams d2y General expression M xx EI 2 dx Standard cases Concentrated load Cantilever WL3 y max 3EI Simply supported WL3 y max 48EI Distributed load wL4 y max 8EI 5wL4 y max 384EI I α=Tan -1 xx Tanθ I yy Angle of Neutral Axis Oblique loading: Complex stresses/strains 1 2 x y 1 2 x y Cos2 xy Sin 2 1 2 1 , 2 x 1 y Sin 2 xy Cos2 2 x y 12 y 4 xy 2 x 2 x p Tan 1 p xy Strains from stresses 1 E1 1 2 2 E1 2 1 Stresses from strains E 1 2 1 1 2 E 2 1 2 1 2 Rectangular (45o) Rosette 1 1 2 2 2 3 2 1, 2 1 3 2 2 1 2 1 1, 2 tan 1 2 3 2 1 3