Report - University of Brighton

advertisement

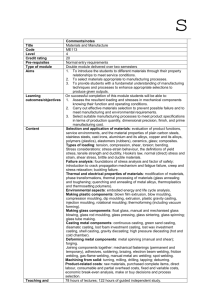

School of Engineering Title Code Level Credit rating Prerequisites Type Aims Learning outcomes/objectives Content Teaching and learning strategies Learning support Manufacture ME216 5 30 credits ME112 or equivalent. Triple module delivered over two semesters. To provide students with an understanding of the basic manufacturing techniques and processes to enhance appropriate selections to produce given outputs. On successful completion of this module students will be able to: select a suitable manufacturing process to meet product specifications in terms of production quantity, dimensional precision, finish and cost. apply the techniques of design-for-manufacture and automation to industrial situations. devise process planning sheets for component manufacture and estimate floor-to-floor times. apply the techniques of quality control. Making plastic components: plastic gravity casting, dip moulding, extrusion, injection moulding, blow moulding, blown film extrusion, thermoforming (including vacuum forming), rotational moulding, compression moulding, transfer moulding, plastic sintering. Making glass components: float glass, manual and mechanised glass blowing, glass rod moulding, glass sintering, glass pressing, glass spinning, glass tube making. Casting metal components: continuous casting, green sand casting, shell casting, disamatic casting, lost wax investment casting, lost foam investment casting, gravity diecasting, pressure diecasting (hot and cold chamber). Metal deformation: forging, extrusion, hot and cold rolling, metal spinning, sheet metal forming. Joining components together: mechanical fastenings (permanent and temporary), adhesives, soldering, brazing, manual metal arc welding, spot welding, friction welding, electron beam welding. Machining processes: machine tool mechanisms, cutting tool geometry, the effects of cutting speeds, feed rates and depths of cut for given material properties, tool life, form tools, broaching, electron beam machining, electrodischarge machining, plasma arc machining, ultrasonic machining, electrochemical machining, electrodischarge wire cutting, electrodischarge grinding, hydrodynamic machining, laser beam machining. Manufacturing automation: Design-for-manufacture. Group technology, component coding and classification systems. Assembly aids: component form and orientation, bowl and cartridge feed, pick and place machines. Industrial machine vision, automated visual inspection, part and position identification and sorting, robot guidance and control. Process planning: machine setting time and cycle time estimation, work flow analysis, charting techniques, floor-to-floor time estimation, synthesis and contingency allowances. Quality control: Tools for improving performance consistency and traceability. Process capability, statistical process control, sources of variation, control charts for attributes. Basic cost characteristics: impact of quantity, shape, tolerance and surface finish, process capability. Product related costs, material, direct labour, consumable and partial overhead costs, fixed and variable costs, economic break-even analysis and process selection. Rapid Prototyping: 3D printing processes, Tooling, CAD link. NC, CNC, DNC machines, CNC fundamentals, manual programming and the application of CNC packages, linked to geometric modellers, to give integrated capability from design to manufacture. Lectures, guest speaker, tutorials, laboratories, and industrial case studies. Reading List: Core: Plummer, S, Manufacturing Systems (Module ME216) Lecture Notes, School of Engineering, University of Brighton. Indicative: 1. Groover, MP, Fundamentals of modern manufacturing – materials, processes, and systems, 2nd ed, pub Wiley, 2002. ISBN 0471400513. 2. Kalpakjian, S, Manufacturing processes for engineering materials, 4th ed, Prentice-Hall, JL/CG Page 1 of 2 08/03/2016 Assessment Brief description of module and/or aims Area examination boards Module team/authors Semester offered Date of first approval Date of last revision Date of approval of this version Version number Replacement for previous module Course(s) for which module is acceptable and status in course School Home External examiner JL/CG 2 2003. 3. Koshal. D, Manufacturing Engineer’s Reference Book, Butterworth-Heinemann, 1993. ISBN 0 750611545. 4. Wetherill BG, Brown, DW, “Statistical process control: theory and practice”, Chapman and Hall,1991. ISBN 0412357003. Salient details (e.g. module descriptor, programme of study, announcements; PowerPoint presentations) will be accessible via studentcentral. 70% examination; 30% coursework Most items we use in our every day lives are manufactured. This module introduces manufacture as a way of adding value to material and describes some of the basic manufacturing processes used to make plastic, glass and metal components for use in mechanical and electrical products. Mechanical Engineering Dr Steve Plummer and Dr Dal Koshal 1 February 2005 February 2005 February 2005 1.0 Resulting merger of ME106 and ME206 MEng/BEng (Hons) Mechanical Engineering portfolio (compulsory) Engineering Dr James Wallbank Page of 2 08/03/2016