Company presentation - Csaba

advertisement

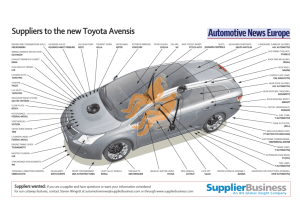

Aluminium High Pressure Die Casting Foundry Management Béla Majoros General Director majoros@csabametal.hu Zoltán Pintér Managing Director z.pinter@csabametal.hu László Sisa Production Manager sisa@csabametal.hu Róbert Gréczi Quality Manager Lajos Dénes Financial manager Csaba Dobrocsi Technical Leader dobrocsi@csabametal.hu Sales Leader k.szentesi@csabametal.hu Klára Szentesi Tünde Solymosi Sales Assistant robert.greczi@csabametal.hu denes@csabametal.hu sotunde@csbametal.hu Csaba Metál Rt. H-5600 Békéscsaba, Kerek 637. Hungary Tel: +36 66 430-881 Fax: +36 66 430-863 E-mail: csabametal@csabametal.hu General Information Owner, Mr Bela Majoros has experience in the casting industry – both gravity and high pressure die casting - for 25 years. He started his first own private business in 1993. The present company CSABA METÁL PLC was founded in 1999 and owned by Bela Majoros. The company manufactures wide range of aluminium high pressure die casting products, which are delivered mainly to the automotive industry. Plant is located in the south-eastern part of Hungary, close to the outer border of the European Union. We are a Tier 2 company to the following brandnames: Audi, BMW, Chrysler, Ford, Jaguar, Mercedes, Nissan, Renault, Rover, Toyota, VolksWagen, Volvo. Our company is employing 240 workers in three shifts. Last year our sales revenue reached EUR 9,12 Million EURO. Csaba Metal PLC is a dynamically developing company. Sales Turnover (HPDC parts) million euro 10 9 8 7 6 5 4 3 2 1 0 9,12 7,64 5,39 3,64 Y 2002 Y 2003 Y 2004 Y 2005 Investment 1,59 1,6 1,3 1,4 1,2 1 1 0,8 0,6 0,7 0,5 0,4 0,4 0,081 0,2 0 1999 million EUR 2000 million EUR 2001 million EUR 2002 million EUR 2003 million EUR 2004 million EUR 2005 million EUR Main Customers (Y 2005) 5,5% 5,5% 5,4% 31,6% 9,5% Continental Teves Alpine Other Trelleborg Linamar Valeo 10,6% 11,6% 20,3% Hella Gázgép Main Products (Y 2005) 2,45% parts for car's brake system 14,81% 42,22% 0,70% parts for car's HIFI set parts for gasarmatures 1,53% different reflectors engine parts 8,64% parts for office furniture 4,09% shift handle 25,55% Other Industry (Y 2005) 15,96% automotive other 84,04% Main Automotive products Surface treated Heat Sink (Anodized) Heat Sink Heat Sink Machined Heat Sink (Finalized with M6 threads) Heat Sink Main automotive products CONTINENTAL TEVES AG. Assembled brake adapter (Screw pressed in) Brake adapter Assembled brake adapter (Screw pressed in) ABS brake part (Finalized with M6 threads) Assembled brake adapter (Screw pressed in) Brake adapter Main automotive products CONTINENTAL TEVES AG. Machined parts (Machining with CNC lathes in-house) 18 different versions Machined parts (Machining with CNC lathes in-house) 18 different versions Spacer Machined parts (Machining with CNC lathes in-house) 18 different versions Main automotive products TRELLEBORG Engine holder Engine holder Suspension parts Engine holder Engine holder Engine holder Main automotive products HELLA Bulb holder Reflector Reflector Main furniture products Table leg „5 stars” chair leg „5 stars” chair leg Polished surface Polished surface Powder coated Furniture products Other products Gas control patrs Gas control patrs Transmission handle Main customers in the local and the foreign markets Trelleborg Automotive (UK, Germany, Spain) Continental Teves AG, Europe Continental Teves, USA, Mexico Steelcase Werndl AG, Germany Frewa GmbH, Germany AS-Motor GmbH, Germany Alpine Electronics Ltd, Japan Hella GmbH, Austria Rába Motor Kft, Hungary Gázgép Kft, Hungary Vitra GmbH., Germany Phoenix-Mecano, Hungary Valeo Switches & Detection Systems Linamar Hungary Ltd. Technologies – Die casting Horizontal, cold chamber die casting machines STP Presse DGK-1000 IDRA OL-950 IDRA OL-800 TRIULZI C-750 WEINGARTEN GDK-700 IDRA OL-560 WEINGARTEN (2 pcs) Zetaquattro GDK-500 IDRA OL-380 IDRA (2 pcs) OL-250 Vertical, cold chamber die casting machines IDRA OLV-250 Horizontal, process controlled moulding cells IDRA OL-1000 IDRA GDK-500 IDRA OLK-400 Technologies – Press Stamping Press stamping machines (deburring) REIS, ITAL Presse (15 pcs) 10 t , 15 t, 20 t, 30 t Technologies – Cleaning, Machining Abrasive wearing (3pcs) Drying (1pc) Shot blasting OTECO (1 pc), COGEIM (1 pc) CNC lathe EMCO (3 pcs), NCT (1 pc), TAKAMAZ X10i with robot (2 pcs) Machining center Brother TC R2A MORI SEIKI SH Junior Measurement and control equipments Dimension control Mitutoyo C544 CNC CMM (With attached statistical program and 3D topography) Mitutoyo surface finish tester Material control ARL-3580B spectroscope Porosity checking Industrial X-ray RTG-MU-15 YXLON Contour checking MAHR CV200 Contourograph Evolution of Quality Control system 2000 ISO 9002:1994 system implementation, succesful certification 2002 QS 9000 implementation, succesful certification 2003 ISO 9001:2000 implementation, succesful certification Certifications of Quality and Enviromental Management Systems 2004 ISO/TS 16949:2002 2004 ISO 14001 2004 ISO 14001 Investments in 2005 500 T moulding cell startup: week 36/2005 IDRA GDK500 process controlled moulding machine Specma/ABB IRB 2400 F/10 robot Stotek/Dosotherm 1200 furnace and trimming press 1000 T moulding cell startup: week 40/2005 IDRA OLK 1002 process controlled moulding machine Specma/ABB IRB 4400 F/45 robot Stotek/Dosotherm 1200 furnace and trimming press 400 T moulding cell startup: week 40/2005 IDRA OLK 400 process controlled moulding machine Specma/ABB IRB 2400 F/10 robot Stotek/Dosotherm 1200 furnace and trimming press