Course Outline - Department of Mechanical Engineering

advertisement

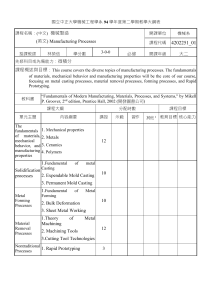

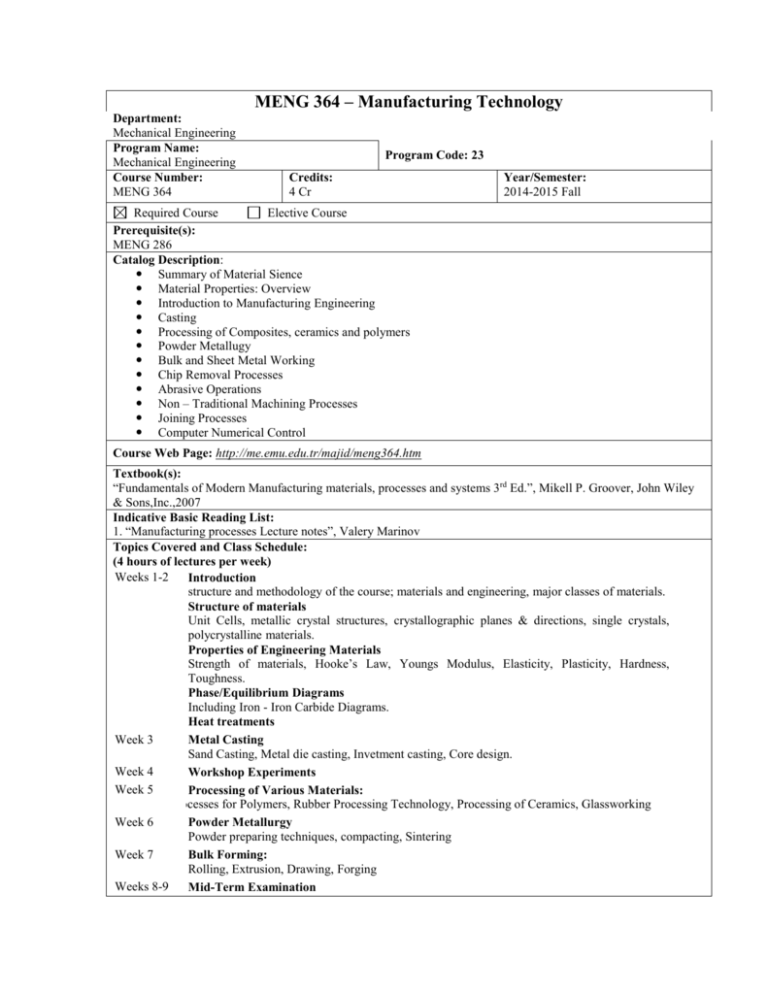

MENG 364 – Manufacturing Technology Department: Mechanical Engineering Program Name: Mechanical Engineering Course Number: MENG 364 Program Code: 23 Credits: 4 Cr Year/Semester: 2014-2015 Fall Required Course Elective Course Prerequisite(s): MENG 286 Catalog Description: Summary of Material Sience Material Properties: Overview Introduction to Manufacturing Engineering Casting Processing of Composites, ceramics and polymers Powder Metallugy Bulk and Sheet Metal Working Chip Removal Processes Abrasive Operations Non – Traditional Machining Processes Joining Processes Computer Numerical Control Course Web Page: http://me.emu.edu.tr/majid/meng364.htm Textbook(s): “Fundamentals of Modern Manufacturing materials, processes and systems 3rd Ed.”, Mikell P. Groover, John Wiley & Sons,Inc.,2007 Indicative Basic Reading List: 1. “Manufacturing processes Lecture notes”, Valery Marinov Topics Covered and Class Schedule: (4 hours of lectures per week) Weeks 1-2 Introduction structure and methodology of the course; materials and engineering, major classes of materials. Structure of materials Unit Cells, metallic crystal structures, crystallographic planes & directions, single crystals, polycrystalline materials. Properties of Engineering Materials Strength of materials, Hooke’s Law, Youngs Modulus, Elasticity, Plasticity, Hardness, Toughness. Phase/Equilibrium Diagrams Including Iron - Iron Carbide Diagrams. Heat treatments Week 3 Metal Casting Sand Casting, Metal die casting, Invetment casting, Core design. Week 4 Workshop Experiments Week 5 Processing of Various Materials: Shaping Processes for Polymers, Rubber Processing Technology, Processing of Ceramics, Glassworking Week 6 Powder Metallurgy Powder preparing techniques, compacting, Sintering Week 7 Bulk Forming: Rolling, Extrusion, Drawing, Forging Weeks 8-9 Mid-Term Examination Week 10 Sheet Metal Forming Bending, Cutting, Deep Drawing, others Weeks 11-12 Machining operations Turning, Milling, Drilling, Planing and shaping, Boaring, Broaching and gear manufacturing. Week 13 Abrasive Processes Grinding, Lapping, Honning, finishing processes Week 14 Joining processes Welding, Types of welding processes, Bazing, Soldeing, Mechanical Assembly Final Examination Week 15: Laboratory Schedule: (1 hours of laboratory or tutorial per week) Week 4 Casting homework Course Learning Outcomes: At the end of the course, student must be able to (1) (2) (3) (4) (5) (6) prepare a pattern and perform the casting. analyze the different production processes learn metal cutting processes learn the undamentals of production machines learn how special and standard parts can be manufactured learn the difference between the metal forming techniques Assessment Method Midterm Exam No 1 Percentage 30% Lab Work(s) 5 10 % Quizzes out of best 5 15% Attendance 5% Final Examination 1 40% Contribution of Course to Criterion 5 Credit Hours for: Mathematics & Basic Science : Engineering Sciences and Design : 4 General Education : 0 Relationship of Course to Program Outcomes The course has been designed to contribute to the following program outcomes: (a) apply knowledge of mathematics, science, and engineering (d) ability to function on multidisciplinary teams. (e) identify, formulate, and solve engineering problems (g) to communicate effectively (i) need for,and an ability to engage in a life –long learning. (k) use the techniques, skills, and modern engineering tools necessary for engineering practice Prepared by: Prof. Dr. Majid Hashemipour Date Prepared: 6 March, 2015