- Through-life Engineering Services

advertisement

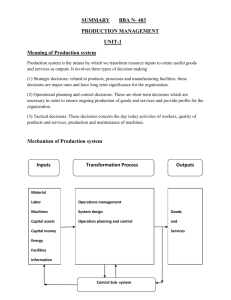

Studio capabilities Dr. Samir Khan www.through-life-engineering-services.org EPSRC Through-life Engineering Services Centre, Building 30, Cranfield University, Cranfield, Bedfordshire, MK43 0AL. +44(0)1234 750111 x2356. samir.khan@cranfield.ac.uk Introduction The Studio is intended to supports the EPSRC Centre for Through-life Engineering Services. It is an integrated laboratory that can be managed with strict manufacturing controls but is flexible enough to fulfil research requirements. The Studio is designed to address a wide range of coupled whole system issues from material analysis for maintenance and repair to process simulation and visualisation. Technologies The Studio provides instrumentation and facilities to perform experiments in supporting all the EPSRC Centre projects. This includes the: • Environmental Test Chamber • Intermittent fault detection kit • Thermographic imaging • Virtual Reality Suite • High-end workstations Test Chamber How does it work? Stress Heat Humidity Airflow Vibration Test Environment unit-under-test Environmental Chamber The lab features the use of a test chamber. It is an important tool for probing the influence of the environment on the technology being used. The choice of environmental variables to regulate, along with control tolerances, depend on the experimental objectives. Chamber specs: -70 to 180 degrees C; at 10 degrees C /min 10-90% humidity Intermittent Fault Detection The NCompass is the state of the art intermittent fault detection and isolation system. It aids in determining the root cause of electronic equipment and NoFault Found (NFF) problems. The kit is being used to capture faults that other traditional test equipment often fails to capture. It can aid in: • Huge time savings for maintainers • Intermittent Fault Detection • Wiring Integrity testing and trending • Product Assurance of electronic integrity • Improved first-time-fix capability • Reductions in Total Ownership Costs Thermoscope This measurement and imaging technology is being used to inspect component degradation, corrosion, disbondings and delamination. Heat transfer Flash heating Metal component surface temperature decay thermal image Thermoscope analyse defect Virtual reality suite The suite is being used to study system architecture design for engineering services. Applications are being developed to visualise and link design rules with system design. The facility allows users to carry out their tasks and perform functions by exchanging information with computer systems in 2D and 3D space. Siemens PLM will extensively be used to visualise the manufacturing process and life cycle mock up designs.