here - Groenewout

advertisement

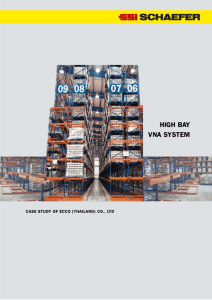

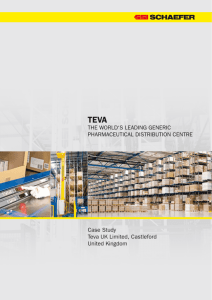

Warehouse & Distribution Management WAREHOUSE (RE)DESIGN Breda, 13-03-2012 Groenewout Ref nr. 9015X012/WD/ld - version 1.0 Wendel Dijker The recommendations, advice and conclusions, mentioned in this report, are based on the information and data provided by client. Savings, operational costs and investment estimates are depending on the assumptions and preconditions stated in this report. Profile Groenewout Founded in 1966, Groenewout provides professional consulting in Logistics and Supply Chains Management. Our core competence has been sharpened in supply chains optimization and detailed designs of manufacturing-, distribution- and fulfillment centers. We place a great deal of emphasis on both the identification and realization of feasible opportunities. Page 2 Our consulting service portfolio Page 3 Our consulting methodology MULTI-DISCIPLINARY Groenewout’s team consists of highly qualified business consultants with unique, complementary disciplines. HANDS-ON More than 40 years of experience in operational environments & implementation processes. INDEPENDENT Groenewout has no formal obligations towards suppliers or contractors whatsoever and always gives an independent advice, keeping the interest of the client as a first priority. INTEGRITY Groenewout highest value is integrity, externally towards client organizations and their employees and internally towards Groenewout employees. PROFESSIONAL • Quantifiable: Quantification is the basis for our advice. • Quality: Highly qualified professionals with more than 150 years of logistics experience. • Leading edge expertise: Groenewout strives to maintain a leading position as a Logistics and Supply Chains Management specialist, creating a continuous learning environment to develop the organization and the individual. Page 4 Quality measured by our clients (Fine) Chemicals Healthcare Electronics 3rd-Party Logistics Service Providers Fast Moving Consumer Goods Page 5 And many other industries Content 1 Introduction 2 Muther‘s Method & Basic Data Document 3 Warehouse concept 4 Evaluation Page 6 1 Introduction (1) Supply Chain Structure Supply Chain Management Assets & facilities Sourcing Manufacturing Warehousing & distribution Transportation Page 7 Customer 1 Introduction (2) Company strategy Logistics strategy Operational concept Logistics process Logistics design requirements Information system requirements Building requirements Page 8 Organization & communication requirements 1 Introduction (3) Facilities Realize Controls Logistics Organization Processess •Organization matrix •Processess •Workinstructions •Racking •MHE •Conveyors •WMS •Interfaces •Building •Building related installations Page 9 Design 1 Introduction (4) Quantitative Qualitative a/o Flexibility Building and facilities costs Labor costs Risk Minimize warehouse costs Quality Logistic equipment costs Efficiency Page 10 2 Muther’s Method & Basic Data Document Approach Product: Which Products? Quantity: What are the quantities? Route: Which route? Systems: What supporting System? Time: What is the time period? Muther’s method Classification of materials Quantification of goods flows STOP Selection of storage and handling method Alt. A Alt. B Alt. C Evaluation of alternatives Choice and engineering of alternative Page 11 Collect and bring all the relevant information (PQRST) in Basic Design Document (BDD) 3 Warehouse Concept Main Topics A Storage Systems B Handling Systems C Overview D Order Picking Method E Order Picking Techniques F IT Page 12 3A Storage Systems Storage systems Handling systems Optimal Warehouse Concept Picking method Picking technique Page 13 3A Storage Systems General Storage systems can be divided into systems for: • Pallet items • Small items • Long goods • Others Page 14 3A Storage Systems Pallet Items (1) Block stacking Page 15 3A Storage Systems Pallet Items (3) Pallet racking - Wide aisles Page 16 3A Storage Systems Pallet Items (2) Pallet racking - Narrow aisles Page 17 3A Storage Systems Pallet Items (4) ASRS or Pallet retrieval Page 18 3A Storage Systems Pallet Items (5) Pallet flow racking / push back racking Page 19 3A Storage Systems Pallet Items (6) Drive-In racking Page 20 3A Storage Systems Pallet Items (7) Pallet racking with satellite Page 21 3A Storage Systems Pallet Items (8) Movable racking Page 22 3A Storage Systems Small Items (1) Static Shelving Page 23 3A Storage Systems Small Items (2) Dynamic shelving Page 24 3A Storage Systems Small Items (3) Case flow racking Page 25 3A Storage Systems Small Items (4) Picking Tray System Mini load Page 26 3A Storage Systems Small Items (5) Paternoster/lift Page 27 3A Storage Systems Long Items (1) Block stacking Page 28 3A Storage Systems Long Items (2) Block stacking Page 29 3A Storage Systems Long Items (3) Cantilever racking Page 30 3A Storage Systems Long Items (4) Automated system with cassettes Page 31 3A Storage Systems Long Items (5) Vertical stacking on pins Page 32 3A Storage Systems Summary (1) Storage systems can be divided into systems for: • Pallets • Small items • Long goods • Other: • Hanging garments (see pictures) • Odd sizes, like • Bikes • Seats, couches • … Page 33 3A Storage Systems Summary (2) storage system Stock per article Number of articles Space utilization orderline / Investment stock rate L L L L A H A H A H A H L Block stack Wide aisles Narrow aisles AS/RS pallets Pallet flow racks Shelves Case flow racks Mini-load Paternoster Carrousel L Low A Average H Categorization and criteria storage systems Page 34 High A H Storage unit L A H Flexibility L A H 3A Storage Systems Summary (3) High level comparison pallet systems Storage Systems Block Stacking Picking Systems Pallet Flow High Bay Block Stacking Pallet Drive-In Pallet Drive-In Pallet Flow Pallets Racking (Wide Aisle) Pallet Racking (Wide Aisle) High Bay Pallets Racking (Narrow Aisle) Pallet Racking (Narrow Aisle) Fine picking Cases or eaches # SKU Page 35 Bulk picking Pallets 3A Storage Systems Summary (4) High level comparison small article systems Storage Systems Picking Systems A-Frame Pallet Racking Case Flow Pallet Racking Case Flow A-Frame AS/RS Mini load AS/RS (Mini load) Shelving Shelving Carrousel Paternoster/lift Paternoster/lift Fine picking (Eaches) # SKU Page 36 Carrousel Case picking 3B Handling Systems (1) Storage systems Handling systems Optimal Warehouse Concept Picking method Picking technique Page 37 3B Handling Systems (2) Electrical Pallet Truck Hand Pallet Truck Page 38 3B Handling Systems (3) Customized pick cart Pick cart with P-t-L system Page 39 3B Handling Systems (4) Roll container/ Dolly Page 40 3B Handling Systems (5) Forklift truck Page 41 3B Handling Systems (6) Horizontal order pick truck Page 42 3B Handling Systems (7) Vertical order pick truck Page 43 3B Handling Systems (8) Reach truck Page 44 3B Handling Systems (9) Combi truck or high bay truck Page 45 3B Handling Systems (10) Conveyor systems Page 46 3B Handling Systems (12) Mini load cranes (ASRS) Page 47 3B Handling Systems (13) Pallet cranes (ASRS) Page 48 3B Handling Systems (14) Side loaders Page 49 3B Handling Systems (15) AGV (Automated Guided Vehicle) Page 50 3C Overview Characteristics for main concepts Cost for Space Concept Storage method MHE Blockstack Floor Forklift truck Wide aisles Pallet racking Reachtruck Narrow aisles Pallet racking Combitruck AS/RS Pallet racking SBA Pallet flow racks Pallet flow racks Orderpick truck Pallet flow racks ptb Pallet flow racks Pick-to-belt Shelves Shelves Trolley Shelves ptt Shelves Pick-to-tote Case flow racks Case flow racks Trolly Case flow racks ptt Case flow racks Pick-to-tote Miniload Case racking Miniload crane L A L Low Page 51 H Equipment cost Labour cost L A A Average H L A H H High 3D Picking Method (1) Storage system Handling system Optimal Warehouse Concept Picking method Picking technique Page 52 3D Picking Method (2) Picking methods • Pick cart, roll container • Electrical pallet trucks, 1 or more pallets • (horizontal/vertical) order pick trucks, combi trucks • Pick-to-belt • Pick-to-tote • Pick-to-shipping box Page 53 3D Picking Method (3) Pick cart Page 54 3D Picking Method (4) Roll container/ Dolly Page 55 3D Picking Method (5) Horizontal order pick truck Vertical order pick truck Page 56 3D Picking Method (6) Combi truck Page 57 3D Picking Method (7) Conveyor belt: pick-to-belt Page 58 3D Picking Method (8) Roller conveyor: pick-to-tote (zone picking) Page 59 3D Picking Method (9) Roller conveyor: pick-into-shipping box (zone picking) Page 60 3E Picking Techniques (1) Storage system Handling system Optimal Warehouse Concept Picking method Picking technique Page 61 3E Picking Techniques (2) • Paper pick list • Collo-labels • Goods-to-Man • RF and scanning • Pick-to-Light • Voice Recognition • Full automated picking (A-frame) Page 62 3E Picking Techniques (3) Handling concepts • Man-to-goods • Goods-to-man / automatic storage • Goods-to-man / hybride (e.g. wide aisles, narrow aisles) (e.g. AS/RS, paternoster) (e.g. pick-to-tote/carton, pick-to-belt) Advantages goods-to-man vs. man-to-goods • Higher productivities • Less picking errors • Better space utilization • Ergonomic working stations Disadvantages goods-to-man vs. man-to-goods • Higher investments • Less flexibility • Limited capacity Page 63 3E Picking Techniques (4) Multi-order picking (sort-while-picking) by P-t-L on pick cart Page 64 3E Picking Techniques (5) RF picking & scanning Page 65 3E Picking Techniques (6) Pick-to-Light Page 66 3E Picking Techniques (7) Voice Recognition Page 67 3E Picking Techniques (8) A-frame Page 68 3E Picking Techniques (9) Page 69 3E Picking Techniques (10) Cost for Space Concept Storage method MHE Blockstack Floor Forklift truck Wide aisles Pallet racking Reachtruck Narrow aisles Pallet racking Combitruck AS/RS Pallet racking SBA Pallet flow racks Pallet flow racks Orderpick truck Pallet flow racks ptb Pallet flow racks Pick-to-belt Shelves Shelves Trolley Shelves ptt Shelves Pick-to-tote Case flow racks Case flow racks Trolly Case flow racks ptt Case flow racks Pick-to-tote Miniload Case racking Miniload crane L A L Low H Equipment cost Labour cost L A A Average H L A H H High Focus off integrated systems like Direct Picking System, Order Distribution System, Order Storage and Retrieval en Horizontale Carrousels with sufficient volume Page 70 3E Picking Techniques (11) 1.000 p i c k r e g e l s 900 800 700 p e r 600 u u r 500 p e r 400 p e r s o o n 300 200 100 Manueel M2G DPS Horizontale Carrousels Page 71 OSR ODS 3F IT General concept (1) Purchase Orders Confirmation S Y S T E M S Sales Orders Confirmation ERP system Supplier System WMS Repair WMS LSP Repair Center LSP CRM system WMS Retailer F L O W S Production Stock At supplier At supplier Own Warehouse Page 72 Retailer Or Shop Customer 3F IT General concept (2) ERP ERP ERP ERP WMS Production site Warehouse Warehouse Page 73 3F IT Warehouse Management & Control System (3) Warehouse Management System Warehouse Control System PLC Miniload PLC Sorter PLC Sorter RF RF RF VAS Receiving Page 74 RF 4 Evaluation (1) Operational Handling Concept Decrease errors Decrease lead time Ordering day X Delivering next day ‘zero defects’ Maximize of consolidation Minimize of operational costs Possibility of Modular systems ‘same day deliveries’ Page 75 4 Evaluation (2) Operational costs Layout drawings & concept drafts Concept description Migration plan Project plan realization Investments Operational FTE calculation Handling Concept Sensitivity analysis Page 76 Capacity calculation Performance guarantee 4 Evaluation (3) Financials • Logistics performance • Investments (CAPEX) • Conceptual concept • Operational costs (OPEX) • Headcount • ROI • Reliability •… • Flexibility • …….. Requirements Risk • Sensitivity • Fullness • Techniques dependency • Conformities basic data • Fall back scenario's •… • Risk of execution • Timeline of realization •… Criteria Weighted Score per concept factor Financials .. Logistics performance .. Risk .. Requirements .. 1 … Total Score 100% Page 77 2 3 4 CONSULTING, ENGINEERING & OPTIMIZATION IN LOGISTICS NETWORKS