supplier

advertisement

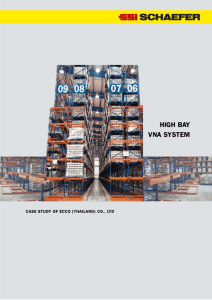

Real Benefits from Pallet Standardization – A Case Study John Talbot – CEO, Logistics Consulting Asia David Edwards, General Manager – Business Development, Loscam Asia Copyright © 2007 Logistics Consulting Asia The business • Background – Multinational FMCG manufacturer – National market leader in beverages – Product produced at multiple factories – mostly rural – Sales primarily in urban areas – Direct delivery to over 300,000 customers – Modern trade increasingly important (and demanding) The business’ logistics challenges • Relatively low value product • Rural sources, but primary markets in towns/cities • Fuel costs rising (oil price & removal of subsidies) • Product damage in transit Logistics cost as high % of revenue • Only 2-3 days pipeline inventory • Growth of modern trade Maintenance of service levels Solution: logistics capability development program • Logistics consultants have been supporting the business since 2005, managing a range of supply chain development projects: – – – – – – – Network analysis (optimal location for new plant lines) Demand / production planning automation Factory off-take time-slotting Logistics skills development Supported by Improved product care pallet Transport cost reduction standardization Factory & depot productivity & performance upgrades Concept development thru piloting • Pool pallets and drive-in racking piloted at 1 factory and 1 depot • Key lessons: – ECR format preferred to hi-stack – Acceptance much higher where training more intense – Acceptance much higher when scale of pilot is substantial (otherwise it has a nuisance factor) – ECR format opens opportunities for packaging cost reduction Pallet standardization benefits sought 1. Reduce pallet acquisition costs 2. Utilize drive-in racking 3. Reduced transport costs & product damage 4. “Soft Benefits” • Operational discipline • Customer service 1. Reduce pallet acquisition costs • Imperative to review “owned” pallets – – – – – – Current 2-way (1220 x 1050) pallets Too expensive (due to high damage rate and loss) Undermine product care due to poor quality Do not support installation of pallet racking Cost of Capital (bank interest) increasing Pallets are normally cannibalized for repairs destroying investment – Headcount and consumables required to repair pallets – Need redundant pallets for peak season – Avge 3 years life 2. Utilise Drive In Racking • Agreement that best alternative is 1200x1000 industry standard pallet “ECR Pallet” • Utilize drive-in racking – Increase storage capacity by 70% • Increase inventory build capacity 3. Reduce Transport Costs & Product Damage • Reduced transport costs – – – – Compatibility with modern vehicles Better vehicle utilization Faster turn-around Increase in direct deliveries to modern trade • Reduced product damage – Due to block-stacking – Due to timber/nail damage – Due to movement in transport 4. “Soft” Benefits • Operational discipline – Better handling practices – Safer work practices • Customer service – Better protection of product through to point-of-sale – Compatibility with modern trade standards LEVEL OF SUPPLY CHAIN SOPHISTICATION Retail Market Maturity HIGH THAI HKG MAL SING PHP INDO CHN VNM IND HIGH INFLUENCE OF MODERN RETAIL TRADE Copyright © 2007 Logistics Consulting Asia Direct to Store – sustainability? SUPPLIER WAREHOUSE SUPPLIER WAREHOUSE Orders Transport Centralised Distribution Driving Efficiencies Deliver on larger vehicles no manual handling SUPPLIER WAREHOUSE SUPPLIER WAREHOUSE Pick by SKU not by individual store order More Trips Possible Priority Unload MODERN TRADE DC’S One consolidated order not one order per store RETAIL - Commercial benefits • Decide on one standard pallet for all & introduce standardization around that pallet • Velocity of product across docks & and for putaway and pick functions • Truck turnaround times and yard capacities • Supplier sponsored pallet hire • Outsource pallet function to professional mgt company • Reduce losses • Remove repair costs • Remove sorting MODERN TRADE DC’S SUPPLIERS – Sales & CS • Reduction in Invoices/missed invoices • Reduction in collections • Reduced credits • Days outstanding/cash flow • Access to forecasting & sales data • Supplier incentives SUPPLIERS – Supplier Operations • Picking task reduced • Wrapping, labeling, loading, paperwork reduced • Reduced number of loaders • Reduction in pallet usage • Pallets always available • Opportunity to modernise – suppliers suppliers, materials handling etc SUPPLIER WAREHOUSE SUPPLIER WAREHOUSE SUPPLIERS – Transportation • Reduction in transport - greater trucks turns • Priority Unloading – night time slots • Reduction in transport management task • Reduced transit damage SUPPLIER WAREHOUSE LOADING 3 – 4 Hours 20 Minutes Bottom Line • Savings in supply chain ~ 2 - 7%+ • No disadvantage philosophy for suppliers • Total supply chain cost analysis critical • Loscam works with suppliers and transporters/3PL’s to ensure smooth transition • Modern trade influence getting stronger amongst SME’s – be prepared and achieve win win Questions? Please contact us at … John Talbot - john.talbot@lcalink.com David Edwards – david.edwards@loscam.com www.lcalink.com www.loscam.com Copyright © 2007 Logistics Consulting Asia