Flexural Strength of Joint Reinforced Block Masonry Walls

advertisement

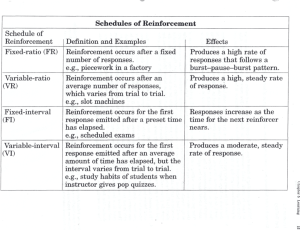

653 FLEXURAL STRENGTH OF JOINT REINFORCED BLOCK MASONRY WALLS by Ahmad A. Hamid Assoc. Professor of Civil Engineering Drexel University Philadelphia, PA, USA Catherine Chia Structural Engineer Yardley Consultants Inc. Yardley, PA, USA Harry G. Harris Professor of Civil Engineering Drexel University, Philadelphia, PA, USA ABSTRACT Wire bed joint reinforcement has been used over the years for control of cracks due to temperature and shrinkage, for continuity in multiple wythe walls and to satisfy arbitrary minimum code requirements in the horizontal direction. However, the structural significance of joint reinforcement in block masonry walls is not well established. This pape r presents an experimental study of the strength of horizontally spanning joint reinforced block masonry walls under out-of-plane lateral loading. Three wall panels were tested to determine the effect of amount of horizontal reinforcement on the wall cracking moment and flexural stength. It is concluded that joint reinforcement does not influence the cracking load but the flexural strength, however, is increased depending on the type and spacing of the reinforcing steel. 654 INTRODUCTION Wire bed joint reinforcement has been used over the years for crack control due to temperature and shrinkage (1, 2), for continuity in multiple wythe walls (3-5) and even to satisfy arbitrary minimum co de requirements in the horizontal direction. However, the structural significance of joint reinforcement in block masonry walls, particularly for seismic resistance, is not well established . There has been relatively few documented tests (6-14) addressing The test the function of joint reinforcement in masonry walls . results indicate that its contribution to load carrying capacity ranges from -10 to 300 percent. This wide range is attributed to variation in. material and geometric properties as well as construction details. Test data are scarce and conflicting. Ali available data are for vertically unreinforced walls, and as such Also, the does not represent reinforced masonry wall behavior. tests were conducted under force control which cannot predict the post-yield behavior required to determine wall ductility. A comprehensive experimental program was conducted at Orexel University to investigate the effects of amount and type of reinforcement, block size, bond type, grouting, and geometric parameters on the behavior of horizontally spanned joint reinforced walls using displacement control input. Results of three walls tested to determine the effect of amount of joint reinforcement on wall flexural capacity are presented. EXPERIMENTAL PROGRAM Materiais The materiais used in the construction of the walls are typical of those commonly used in building construction in the United States. Concrete Blocks: The physical and mechanical properties of the 6 in. nominal hollow concrete blocks used are listed in Table 1. Morta r: Cement-lime mortar consisting of 1 part Type I Portland cement, 3/8 part hydrated lime, and 3-1/2 parts sand, conforming to requirements for type S mortar described in ASTM C270-82 (15), was used in the construction of the wall panels. An • 655 averag e water/cement ratio of 0.74 was used to obtain the average initial flow of 110 percent. Cylindrical control specimens 2-in. diameter by 4 in. high were obtained following procedures similar to ASTM C109-80 (15). The cylinders were air-cured alongside the companion walls and tested under axial compression at approximately the same age as the walls. The average compressive strength obtained for the mortar specimens was 2890 psi. TABLE 1 Properties of Concrete Masonry Units Description ASTM Property Density, pcf Absorption, pcf 0/0 Moisture Content, % Initial Rate of Absorption, gm/min/30 in. 2 Saturation Coefficient Axial Compressive Strength, psi, for Net Area for Gross Area Splitting Tensile Strength, psi C140-75 C140-75 102 11.0 10.8 3.83 C140-75 C67-83 C67-83 C140-75 C1006-84 43.9 0.721 2920 1550 280 Grout: Coarse grout consisting of 1 part Type 11 Portland cement, 3 parts sand and 2 parts 3/8-in. pea gravei; conforming to the requirements described in ASTM C476-83 (15), was used in the construction of the wall panels. A grout aid from Sika Corporation (Sika mix 119/120) was premixed in the water and added to the base mix to provide a more workable grout (9-10 in. slump) which is easy to pour and consolidate. Core drilled cylinders 1-3/4-in. diameter by 3-1/2 in. high were used as control specimens. The average compressive strength of the grout was 1790 psi. Reinforcement: Prefabricated truss type wire reinforcement from Dur-O-Wal, Inc. conforming to ASTM A82-79 (16) was used as horizontal reinforcement. Properties of the two types (standard and 656 extra heavy) are listed in Table 2. TABLE 2 Properties of Joint Reinforcement Type Description Standard Extra Heavy Yield Strength, psi Ultimate Strength, psi Modulus of Elasticity, psi Strain, in./in Reduction in Area, % Elongation, % 98100(a) , 103,000 29 ,700 ,000 0.005(b) 48.7 2.3 97,700(a) 102,000 28,700,000 0.005(b) 47.5 2.3 (a) at 0.5% extension under load (b) at yield load Test Specimens Three wall panels of four courses high by 5 units long were constructed in running bond with face shell mortar bedding . The typical panel was made up of three full courses in addition to a half course at the bottom and at the top (see Figure 1), to represent a typical wall strip cut from center-of-block to center-of-block. The panel size was 32 in . wide by 80 in . long. Horizontal reinforcement was present in the three walls (W1, W2, W3) in the following configurations , . respectively: a) standard Dur-O-Wal Truss placed in every course, b) standard Dur-O-Wal Truss placed in every other course, c) extra heavy Dur-O-Wal Truss placed in every course. The amount of horizontal reinforcement ranged from 0.056 percent (Iess than code minimum requirement) to 0.16 percent (greater than code minimum requirement). The quantity of steel reinforcement used was based generally on the guidelines presented in the 1985 UBC (17) and the 1983 ACI 531-79 (18) , which specify the minimum amount of wall reinforcement in either the vertical or horizontal direction to be 0 .07 percent of the respective gross cross-sectional 657 1- 80" ~I Dur-Q-Wa 1 (Typ . ) #4 Rebar (Typ . ) (a) Joint reinforcement every course (Walls Wl and W3) Dur-O-Wal (Typ.) #4 Rebar (Typ.) (b) Joint reinforcement every other course (Wall W2) Figure 1. Test specimens 658 area of the wall. In addition, the sum of the percentages of vertical and horizontal reinfo rcement is specified to be at least 0.2 percent. Four No. 4 bars (0 .18%) we re used for vertical reinforcement. Grouting was performed at 2-ft intervals at the hollow cores that contained the vertical reinforcement. Test Set-up and Instrument ation The walls were simply supported at the end and had a span of 74 in . from centerline to centerline of the supports (one pinned and the other roller support) . Two equal line loads, transverse to the span length, were applied to the face of each wall (with the wall in a vertical position) at the third points . Deflection and strain instrumentation were placed at specific locations on the walls. Figure 2 shows a schematic of the experimental set-up. A 55 kips MTS hydraulic actuator was operated under displacement control at a constant rate through a computer-based measurement and control system. Data acquisition was carried out on the the same computer system. A displacement ramp was appl ied slowly and load was measured by the actuator precision load cell. DISCUSSION OF TEST RESULTS Crack Pattern and Mode of Failure Crack patterns of the three walls are shown in Figure 3. The basic pattern of cracking was one of head joints separation and vertical Cracking splitting of the masonry units on the tension face. occurred first in the mortar joints at low loads in the constant moment region between the lines of applied load . The cracks then propagated into the face-shell area in the same region. Once the crack pattern in the pure moment region had been established, load redistribution in the wall panel occurred , as evidenced by the appearance of a set of vertical cracks just beyond the pure moment region. The load at which these cracks in the shear span occurred was close to the failure load. Failure was preceeded by widening of cracks with no further addition to the crack pattern . A loud snapping noise was heard shortly after the ultimate load was reached in the wall panels indicating the rupture of the joint reinforcement. 659 r- í Support Tube (Typ.) J r-- r r Wall Panel Load Tube (Typ.) ,.-!- f- Distribution Beam ~ ~ N M /L - '-- HydraullC Actuator I, .1 80" (a) Elevation view (not to scale) Hydraulic Actuator Strain Instrumentation Beam Wall Panel Roller Support Instrumentation 25" I- 24" .1 e (b) Top view (not to scale) Figure 2. Test set-up 25" ~I I 3" , sl \ SlAEHdij9 2M LLI?M • I SlAZH<Rl9 t 1I Y I '\ ,I 099 I 661 Wall Flexural Strength The ultimate loads of the three walls are given in Table 3. Ultimate load increased when the amount of horizontal reinforcement in the wall increased, and joint reinforcement increased the flexural strength over walls without joint reinforcement. For walls without joint reinforcement the ultimate strength is assumed to be the cracking strength of the masonry assemblage. In comparing the ultimate load with the cracking load, it is found that joint reinforcement in every course increased the flexural strength by 220 to 280 percent depending on the type of reinforcement (standard or extra heavy) and joint reinforcement in every other course increased the flexural strength by just 64 percent (Table 3). TABLE 3 Summary of Test Results Wall % Steel Pcr(lbs) Pu(lbs) PiPcr W2 W1 W3 0.056 0.11 0.16 1030 938 1290 1700 3010 4910 1.64 3.20 3.80 CONCLUSIONS The following conclusions are drawn from observation of the tests and analysis of the test results: (1) The walls were observed to share a common mode of failure, that of head joints separation and splitting of the face-shells in the tension zone. The complexity of the crack pattern was found to be dependent on the spacing of the joint reinforcement . Walls with joint reinforcement in every course had a more developed crack pattern than walf with joint reinforcement in just every other course. (2) Joint reinforcement did not influence the cracking load significantly but it did act to control and distribute the cracks within the failure region. A minimum amount of joint 662 reinforcement is required to maintain a safe ratio between the cracking load and the ultimate load. Joint reinforcement in every course adequately provides this ratio. (3) Joint reinforcement increased the flexural strength of block masonry walls as compared to unreinforced walls. Joint reinforcement in every other course increased the flexural strength by about 64 percent while joint reinforcement in every course increased the flexural strength by 220 to 280 percent. Therefore, the code minimum steel requirement in the horizontal direction (0.07%) has the desirable effect of increasing the wall flexural strength by over 64 percent as compared to unreinforced walls. ACKNOWLEDGMENTS The support of this research by the National Science Foundation through grant No. ECE-8319178 to Drexel University is gratefully acknowledged. Tests were conducted using an MTS loading system funded partially by the National Science Foundation through grant No. ECE-8412474. Mason's time was made available through the Delaware Valley Masonry Institute and D.M. Sabia and Company and is gratefully acknowledged. REFERENCES 1. Bartlett, W.H., "Masonry Wall Reinforcement - When, Where, How Much?," C/M Magazine, March 1965. 2. ----, "Ladur Type Masonry Wall Reinforcement, DUR-O-WAL," ICBO Evaluation Report No. 2292, International Conference of Building Officials, Whittier, California, January 1982. 3. Bortz, S.A., "Investigation of Continuous Metal Ties as a Replacement for Brick Ties in Masonry Walls," Technical Bulletin No. 67-5, DUR-O-WAL, Inc., Northbrook, IlIinois, 1967 . • 663 4. Randall, F.A. and Panarese, W.C., Concrete Masonry Handbook for Architects. Engineers, Builders. Portland Cement Association, Skokie, IlIinois, 1976. 5. Schneider, R.R. and Dickey, W.L., Reinforced Masonry Design, Prentice-Hall, Inc., Englewood Cliffs, N. J., 1980. 6. Cox , F.W. and Ennenga, J.L. , "Tranverse Strength of Concrete Block Walls," Proceedings of American Concrete Institute, Vol. 54, 1958, pp. 951-960. 7. Hedstrom, R.O., "Load Tests of Patterned Concrete Masonry Walls," Proceedings of American Concrete Institute, Vol. 57, 1961, pp. 1265-1286. 8. Mattison, E.N. and Churchward, G., "Some Tests on the Bending Strength of Concrete Masonry in Running Bond," Division of Building Research, Melbourne, Australia, 1969. 9. ----, "The Structural Role of Joint Reinforcement in Concrete Masonry," Technical Bulletin No. 99, National Concrete Masonry Association, Herndon, Virginia, 1978. 10. DeVekey, R.C and West, H.W., "The Flexural Strength of Concrete Blockwork," Building Research Establishment, London, October 1979. 11. Anderson, D.L., Nathan, N.D., Cherry, S. and Gajer, R.B., "Seismic Design of Reinforced Concrete Masonry Walls," Proceedings of the Second Canadian Masonry Symposium, Ottawa, Canada, June 1980, pp. 181-196. 12. Cajdert, A., "Laterally Loaded Masonry Walls," Ph .D Thesis, Chalmers University of Technology, Goteberg, Sweden, 1980. 13. Dickey, W.L., "Joint Reinforcement and Masonry," Proceedings of the Second North American Masonry Conference, College Park, Maryland, August1982, pp. 15-1 - 15-15. 14. Dickey, W.L. and Catani , M., "Joint Reinforcement is Also Structural," Proceedings of Concrete International. ACI , Vol. 5, 664 No. 6, June 1983, pp. 32-39. 15. American Society for Testing and Materiais Standards, Section 4, Vol. 04.05, 1984. 1984 Annual 16. American Society for Testing and Materiais Standards, Section 1, Vol. 01.04, 1984. 1984 Annual 17. International Conference of Building Officials, "Masonry Codes and Specifications," Uniform Building Code, Chapter 24, Whittier, California, 1985. 18. American Concrete Institute, "Building Code Requirements for Concrete Masonry Structures," ACI Standard 531-79, Detroit, Michigan, 1983. •