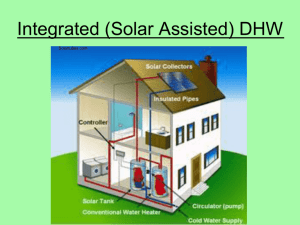

MO-405 Maintenance and Operation of Active Solar Heating Systems

advertisement