ME252SolarCollectorExpt

advertisement

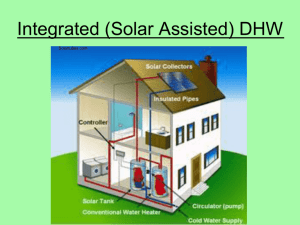

ME 252 Lab – Solar Collector Experiment Objective: to measure the performance of an active, evacuated tube solar collector system for domestic hot water. Specifically, determine the system efficiency at two different flow rates. Background: Evacuated tube solar collectors are more efficient than conventional flat plate collectors since heat losses from the absorber are suppressed by an evacuated space between the transparent glazing (glass) and the absorber surface. A perfect vacuum eliminates conduction and convection heat transfer; thus, the only thermal losses are due to radiation exchange between the absorber surface and glazing. In practice, a perfect vacuum is not achievable and conduction losses will also occur through other parts of the system such as the collector framework. The collector system to be tested was manufactured by the Sunmaster Corporation and uses the Owen-Illinois “Sunpack” evacuated tubes. The design consists of concentric glass tubes with the annulus evacuated. The inner glass tube is coated with a selective surface – it has high solar absorptivity and low infrared emissivity. A small copper tube is located at the center of the absorber tube. Water enters the collector at the bottom of the annular space separating the absorber tube and the copper tube; it then flows upward to the top of the collector and returns downward through the copper tube. The original Sunmaster panels consisted of eight evacuated tubes connected in parallel through a single header, or manifold. Refer to handouts. The experiment was designed, built, and tested by a Chico State Mechanical Engineering senior design team in Spring 1997. It was configured as an active, closedloop water heater by incorporating a small centrifugal pump and a five-gallon storage tank. Measurement of water flow rate and water temperature are accomplished by a glass rotameter and several thermocouples, respectively. Only six of the original eight evacuated tube collectors are currently operational. Theory: Solar collector efficiency is the fraction solar energy intercepted by the collector aperture that is ultimately transferred to the circulating fluid (water). It is computed from c mc p,av Tf T i Ac Gsun t (1) where m is total mass of water in the system, cp,av is the average specific heat of the stored water, Tf is the average final temperature of the water, T i is the average initial temperature of the water, Ac is the collector aperture area, Gsun is the instantaneous solar irradiation, and t is the measurement time interval. The summation is performed over the testing time period. Rev. 040831 1 Apparatus and Instrumentation: Sunmaster evacuated tube solar panel Grundfos variable-speed centrifugal pump Gate valve for controlling flow Glass tube rotameter Three K-type thermocouples LI-COR LI-200SA pyranometer Kipp & Zonen pyranometer Fluke Hydra data logger PC with Hydra data acquisition software Rotameter Calibration: 2 Qind 1.9172Qact 0.0302Qact where Qind = indicated volume flow rate in gpm Qact = actual volume flow rate in gpm Experimental Procedure: Special Precautions Never operate the pump dry as this may cause impeller failure. Always make sure that the storage tank has been filled before starting the pump. Always fill the system with water before moving it to a sunny location. Failure to do so may result in thermal shock and glass tube breakage when the system is filled. Pre-start 1. Inspect the system to ensure that all plumbing connections are secure. Note that the water flows from the bottom of the storage tank to the pump, through the rotameter, through the collector tubes, and then back to the top of the storage tank. 2. Measure the collector aperture dimensions of the six operational tubes. Be sure to include the parabolic reflectors. 3. Fill the system with water using the calibrated water jug. First, open the gate valve and fill the storage tank with five gallons of water. Turn on the pump (plug in power cord) to fill the collector tubes. Then add four more gallons of water to the storage tank. Secure lid to tank and unplug the pump. 4. Move the solar water heater unit and data acquisition cart to a sunny location. Use the hydraulic jack to tilt the collector so that it is approximately perpendicular to the sun’s rays. This alignment can be done by using the shadow cast by a frame member. Rev. 040831 2 Data Collection 1. Turn on the pump and adjust the gate valve to yield a volume flow rate of 2.0 gpm (refer to the rotameter calibration equation). 2. Insert the input module into the Fluke Hydra data logger. Turn on the data logger and boot the PC. Start up the Hydra software and check the configuration. Make sure you are using the correct setup file. Set the measurement scan to “slow” and the time interval to 30 seconds. Enable data recording and create a file that data will be written to. Make sure the time tag is set to “Elapsed time” and the data recording is set to “Amend to file”. 3. Start data logging and set up a Quick Plot to monitor temperatures and solar irradiation. Make sure the sensors are yielding reasonable values. 4. Collect data at this flow rate for approximately one hour, then stop data logging. 5. Adjust the gate valve to yield a flow rate of 5.0 gpm. Reorient the collector if necessary. 6. Start data logging for another hour. Shutdown 1. Stop data logging and download your data file to a floppy disk. Exit the program, turn off the Hydra, and shut down the PC. 2. Unplug the pump and move unit into the shade. Empty the system by attaching a garden hose to the fitting at the top of the storage tank. Run the garden hose to the grass and start the pump. Open the gate valve completely and run the pump until the tank is empty. Allow all water to drain from the system after unplugging the pump. 3. Disconnect the input module from the Hydra and roll the equipment back into the lab. Results: Plot the storage tank temperature versus time for the 2 and 5 gpm tests on the same graph. Connect data markers with a straight line (no smoothing). Compute the (overall) collector efficiency at each flow rate for the entire testing period. Divide each test into 10 minute periods and compute the collection efficiency for each period. Summarize these results in a neat table. Questions: 1. Are the temperature versus time plots linear? Explain why or why not. 2. Compare the overall collection efficiencies for the two flow rates. Are they significantly different? Explain why they may be different. 3. What trends, if any, do you observe in the collection efficiencies computed for the 10-minute periods? Explain these trends. Rev. 040831 3