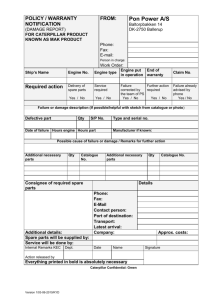

Customer approach in the relocation of spare part warehouse

advertisement