UNITED STATES OF AMERICA BEFORE THE NATIONAL

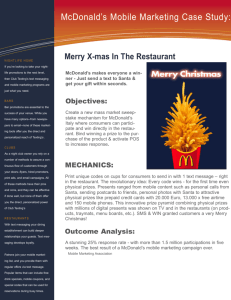

advertisement