Chem M52LC/H52LC Experiment 2 1 Pre-lab Questions

advertisement

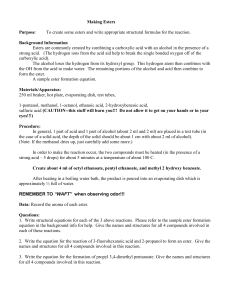

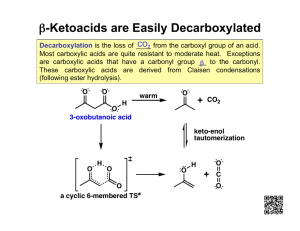

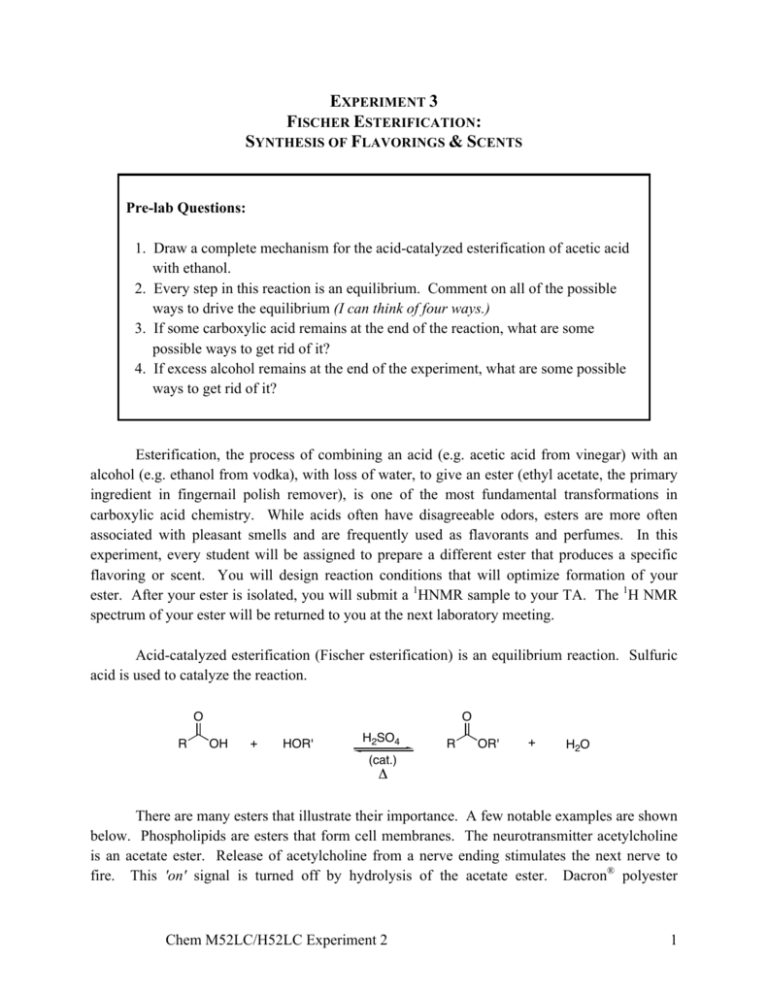

EXPERIMENT 3 FISCHER ESTERIFICATION: SYNTHESIS OF FLAVORINGS & SCENTS Pre-lab Questions: 1. Draw a complete mechanism for the acid-catalyzed esterification of acetic acid with ethanol. 2. Every step in this reaction is an equilibrium. Comment on all of the possible ways to drive the equilibrium (I can think of four ways.) 3. If some carboxylic acid remains at the end of the reaction, what are some possible ways to get rid of it? 4. If excess alcohol remains at the end of the experiment, what are some possible ways to get rid of it? Esterification, the process of combining an acid (e.g. acetic acid from vinegar) with an alcohol (e.g. ethanol from vodka), with loss of water, to give an ester (ethyl acetate, the primary ingredient in fingernail polish remover), is one of the most fundamental transformations in carboxylic acid chemistry. While acids often have disagreeable odors, esters are more often associated with pleasant smells and are frequently used as flavorants and perfumes. In this experiment, every student will be assigned to prepare a different ester that produces a specific flavoring or scent. You will design reaction conditions that will optimize formation of your ester. After your ester is isolated, you will submit a 1HNMR sample to your TA. The 1H NMR spectrum of your ester will be returned to you at the next laboratory meeting. Acid-catalyzed esterification (Fischer esterification) is an equilibrium reaction. Sulfuric acid is used to catalyze the reaction. O R O OH + HOR' H2SO4 R OR' + H2O (cat.) ! There are many esters that illustrate their importance. A few notable examples are shown below. Phospholipids are esters that form cell membranes. The neurotransmitter acetylcholine is an acetate ester. Release of acetylcholine from a nerve ending stimulates the next nerve to fire. This 'on' signal is turned off by hydrolysis of the acetate ester. Dacron® polyester Chem M52LC/H52LC Experiment 2 1 (polyethylene terephthalate, or PET) is a polymer is used in synthetic fibers, beverage & food containers, and in engineering resins. PET is made by esterification of terepthalic acid and ethylene glycol. Representative Important Esters O H3N O P O O O O O N O O a phospholipid acetyl choline O HO O O O O O O O O O Dacron® polyester n OH O The Flavorings and Scents you will Synthesize: O O O O O O O O O Ph O A B C D E banana runts orange rind fruity tropical "Juicy Fruit" fruity/floral O Ph O O O O O Ph O O O O F G H I J rose/honey apricot/pear floral fruit cocktail or "Rockstar Energy Drink" pineapple O O O O O O O Ph O Ph O Ph O K L M N O fruity tropical or raspberry pina colada honey cinnamon/citrus rose/honey OH O OH O O O O O P Q R minty fruity apple wintergreen Because Fischer esterification is an equilibrium process, and the stability of the starting carboxylic acid and product ester are similar, the reaction must be driven to completion. This is Chem M52LC/H52LC Experiment 2 2 generally done by using an excess of one of the starting materials. For some of the above esters, it will be best to use an excess of alcohol. For others, it will be better to use an excess of the carboxylic acid. Two procedures will be shown, one that uses excess alcohol, and one that uses excess carboxylic acid. It is up to you to determine which procedure will be best for synthesis of your ester. Careful consideration should be given to ease of removal of either the excess carboxylic acid or excess alcohol, and your choice will depend on the structures of the alcohol and carboxylic acid for your particular ester. Consider the bp/mp/solubilty of your ester and alcohol, the availability of reagents supplied for this experiment, and the price of your starting materials (use Aldrich prices since all chemicals were purchased from the Aldrich catalog. The Aldrich catalog is available in the lab and online @ www.sigmaaldrich.com.) Reagents used in excess should be inexpensive and easily separated from your product ester. Since different esters will give different yields, you will be graded most heavily on the thought given to your experimental design and the purity of your ester as determined by 1H NMR and IR. CAUTION Wear gloves and conduct all aspects of this procedure in a hood. Low molecular weight carboxylic acids are especially malodorous, and therefore the reaction vessels must be sealed when transported between the microwave reactor and the hood. Disposable gloves used to handle these carboxylic acids should be placed in a solid waste container to prevent fumes from entering the lab space. All of the carboxylic acids are irritants with prolonged exposure and can be corrosive in concentrated solutions. Avoid skin contact. All of the alcohols are flammable and should be handled in the absence of any source of ignition. 1-Pentanol is a lachrymator, causing irritation to the mucous membranes. Methanol is highly toxic if ingested or absorbed through the skin. Sulfuric acid is corrosive and may cause severe burns. Diethyl ether & acetone are flammable irritants that may cause drowsiness or dizziness if inhaled. Hexanes is flammable and is a neurotoxin. When smelling the ester product, make sure to waft the smell towards your nose. Procedure A using excess alcohol (use alcohol as solvent: ethanol, methanol only!) Chem M52LC/H52LC Experiment 2 3 To a microwave vial containing a stirbar, add 10 mmol of the carboxylic acid assigned to you, followed by 3.0 ml of or the alcohol. Carefully add ≈ 0.25 ml of conc. sulfuric acid while swirling the reaction mixture. Place the cap insert and screw-on cap on top of the vial, twisting closed with the block next to the microwave. If there are eight or more students in the lab, use the Esterifications 1 microwave method, which consists of a 3-minute ramp period and 3-minute hold temperature period at 120°C. This sequence also includes a 20-minute cool down period for the reaction to reach <50°C. If there are fewer than eight students in the lab, use the Esterifications 2 microwave method. Transfer the reaction solution into a separatory funnel containing 40 mL water. Add 40 mL ether and mix thoroughly, then separate the layers. Wash the organic layer with saturated NaHCO3 solution (2 x 30 mL). Wash the organic layer with brine (saturated NaCl solution, 1 x 20 mL). Dry the organic layer with MgSO4, filter the drying agent, and remove the solvent by rotary evaporation. Calculate the percent yield. Obtain an IR spectrum and assign the important peaks to your product and other impurities, such as the starting materials and solvents used. Prepare and submit a 1H NMR sample. Be sure to interpret the 1H NMR spectra for your ester. Based on the 1 H NMR spectra, report the purity of your ester. Procedure B (using excess carboxylic acid) To a microwave vial containing a stirbar, add 10 mmol of the alcohol assigned to you, followed by 3.0 ml of the carboxylic acid. Carefully add ≈ 0.25 ml of conc. sulfuric acid while swirling the reaction mixture. Place the cap insert and screw-on cap on top of the vial, twisting closed with the block next to the microwave. If there are eight or more students in the lab, use the Esterifications 1 microwave method, which consists of a 3-minute ramp period and 3-minute hold temperature period at 120°C. This sequence also includes a 20-minute cool down period for the reaction to reach <50°C. If there are fewer than eight students in the lab, use the Esterifications 2 microwave method. Transfer the reaction solution into a separatory funnel containing 40 mL water. Add 40 mL hexanes, and mix thoroughly, then separate the layers. Wash the organic layer with water (2 x 40 mL). Wash the organic layer saturated NaHCO3 solution (2 x 30 mL), then wash the organic layer with brine (saturated NaCl solution, 1 x 20 mL). Dry the organic layer with MgSO4, filter the drying agent, and remove the solvent by rotary evaporation. Calculate the percent yield. If >100% yield is calculated, there may be excess carboxylic acid. This can be removed by repeating the extraction process. Obtain an IR spectrum and assign the important peaks to your product and other impurities, such as the starting materials Chem M52LC/H52LC Experiment 2 4 and solvents used. Prepare and submit a 1H NMR sample. Be sure to interpret the 1H NMR spectra for your ester. Based on the 1H NMR spectra, report the purity of your ester. Post-lab Report: In your post-lab, discuss any impurities present, and suggest procedure modifications that would improve the yield and purity of your product. Did you choose the right procedure? Is Fischer esterification a suitable procedure for preparation of your ester, or are there other methods for ester synthesis that would be more appropriate for your particular ester? Finally, look up a literature preparation of your ester, and compare the purity and yield achieved in the literature prep. How do your results compare? Post-lab Questions: 1. What are the best ways to determine if any residual acid is mixed in with your ester? Consider mp, NMR, IR, & UV and comment on the usefulness of each. 2. Concentrated sulfuric acid is used as a catalyst for Fischer esterification. Why is sulfuric acid needed if another acid, the carboxylic acid is already present? 3. What is the purpose of the sodium bicarbonate solution in the isolation step? What gas was evolved during this washing step? Write a balanced equation for the reaction that produced the gas. 4. Using the Twelve Principles of Green Chemistry handout, what principles does this experiment illustrate? Be sure to look at side products, stoichiometry (to see if there are excess reagents), and the safety of by-products. 5. How might you improve the “greenness” of this synthesis? Chem M52LC/H52LC Experiment 2 5 Twelve Principles of Green Chemistry 1. Prevent waste: Design chemical syntheses to prevent waste, leaving no waste to treat or clean up. 2. Design safer chemicals and products: Design chemical products to be fully effective, yet have little or no toxicity. 3. Design less hazardous chemical syntheses: Design syntheses to use and generate substances with little or no toxicity to humans and the environment. 4. Use renewable feedstocks: Use raw materials and feedstocks that are renewable rather than depleting. Renewable feedstocks are often made from agricultural products or are the wastes of other processes; depleting feedstocks are made from fossil fuels (petroleum, natural gas, or coal) or are mined. 5. Use catalysts, not stoichiometric reagents: Minimize waste by using catalytic reactions. Catalysts are used in small amounts and can carry out a single reaction many times. They are preferable to stoichiometric reagents, which are used in excess and work only once. 6. Avoid chemical derivatives: Avoid using blocking or protecting groups or any temporary modifications if possible. Derivatives use additional reagents and generate waste. 7. Maximize atom economy: Design syntheses so that the final product contains the maximum proportion of the starting materials. There should be few, if any, wasted atoms. 8. Use safer solvents and reaction conditions: Avoid using solvents, separation agents, or other auxiliary chemicals. If these chemicals are necessary, use innocuous chemicals. 9. Increase energy efficiency: Run chemical reactions at ambient temperature and pressure whenever possible. 10. Design chemicals and products to degrade after use: Design chemical products to break down to innocuous substances after use so that they do not accumulate in the environment. 11. Analyze in real time to prevent pollution: Include in-process real-time monitoring and control during syntheses to minimize or eliminate the formation of byproducts. 12. Minimize the potential for accidents: Design chemicals and their forms (solid, liquid, or gas) to minimize the potential for chemical accidents including explosions, fires, and releases to the environment. Anastas, P. T.; Warner, J. Principles of Green Chemistry. In Green Chemistry: Theory and Practice; Oxford University Press: New York, 1998; pp 29–55. Chem M52LC/H52LC Experiment 2 6