Fisher Esterification Introduction: The flavor and fragrance industry

advertisement

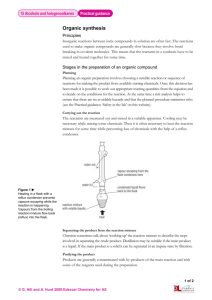

Fisher Esterification Introduction: The flavor and fragrance industry relies heavily on small, volatile organic compounds to create pleasant odors or tastes. Many of these compounds, which are often found in mixtures of naturally-occurring substances called essential oils, bind to our olfactory or taste receptors (for example, oil of wintergreen or oil of cloves, which are single organic molecules). Some molecules in the flavor and fragrance industry, however, are synthetic substitutes that fool our brain into thinking we have sampled by taste or smell, the natural compounds. These artificial flavorings and odors, which also bind to the olfactory and taste receptors, have been used because they are easier and cheaper to obtain, and retain the same aromatic (not the chemical term, but the fragrance meaning) characteristics that the natural compounds possess. Given this, entire industries have developed with these compounds as their foundation: the artificial spice industry, soap industry, and perfume industry are all significant employers of organic chemists. Some of the best examples of natural and synthetic flavor and odor compounds come from the class of organic compounds known as esters. Chemically, an ester is the condensation product that results when a carboxylic acid is reacted with an alcohol. Water is liberated in this reaction, which is why we call it a condensation reaction. Many carboxylic acids are foul smelling (butyric acid = body odor/vomit, acetic acid = vinegar), but when reacted with an alcohol, they can have wide-ranging flavors and fragrances, such as pineapple, “Juicy Fruit,” or apple, some of which are below. Of course the hydrolysis of the ester returns the original pungent properties of the carboxylic acid. In this laboratory, you will be preparing esters which have pleasant odors by a reaction called the Fisher esterification. Fisher Esterification A Fisher esterification is the condensation reaction between a carboxylic acid and an alcohol that occurs in the presence of a mineral acid (normally, H2SO4 or HCl). The mechanism for this reaction is shown below for the synthesis of the ester methyl butyrate, which has an apple fragrance/flavor. First, protonation of the carbonyl oxygen lowers the carbonyl LUMO (*) sufficiently for addition of the weakly nucleophilic solvent, methanol. Within the tetrahedral intermediate, proton transfer occurs to generate water as a good leaving group. Reformation of the carbonyl bond by elimination of water generates the protonated ester. Loss of the proton then regenerates the acid catalyst and provides the product ester in a reaction that is called a nucleophilic acyl substitution reaction. This reaction occurs at high temperatures and can be pushed to completion by removing water as it is formed. Performing the reaction in the alcohol solvent (methanol in this example) also favors ester formation in this thermodynamically controlled procedure. For your experiment, we will be using microwave irradiation as the heat source to accelerate the reaction. Microwaves are a good source of energy for generating a localized source of heat that is more efficient than an oil bath. In this way, reactions can occur faster because the reaction flasks can be heated beyond the boiling point of the reagents. This is an environmentally-friendly technique that has become very popular in both industrial and academic settings, in what is commonly referred to as “green chemistry.” What should you learn by running this experiment? You will be introduced to an important technique that is used by organic chemists to purify organic compounds: distillation. Distillation is used to purify low-boiling liquids by heating the liquids into the vapor state and then recondensing the vapors back into the liquid state. You will be performing a simple distillation that allows you to collect different fractions of a condensing liquid simply by heating a liquid to its boiling point. You will be assigned a carboxylic acid and an alcohol and synthesize an ester via Fisher esterification. You will purify your ester by distillation after liquid-liquid extraction. Consider the following scenario for this experiment: You are employed as an organic chemist at a local start-up company that is trying to develop new flavorings/fragrances for soft drinks. You have been given a series of carboxylic acids and alcohols and have been instructed to make combinations of these two substrates to create different esters and look for compounds that have unique aromas (NOTE: at no point are you actually going to taste these substances!). References: 1. Pavia, D. L.; Lampman, G. M.; Kritz, G. S.; Engel, R. G. Introduction to Laboratory Techniques, 4th Ed. Thomson Brooks/Cole: Mason, OH, 2006; pp 106-108. Fisher Esterification Equipment: Microscale glassware kit 25 and 50 mL beakers 10 mL graduated cylinder 5 mL syringes and needles 1 mL syringes and needles Pasteur pipets Capillary tubes Cotton Scintillation vials and caps NMR tubes HPLC vials Thermowells Stir bars 15 mL Falcon tubes MARS microwave vessels Chemicals: Acetic acid Propionic acid n-Propanol Isopentyl alcohol 2-Methyl-1-propanol Sulfuric acid Sodium bicarbonate (sat. aq.) (2 x 500 mL) Sodium chloride (sat. aq.) (2 x 500 mL) Deionized water Anhydrous sodium sulfate Methanol (2 x 500 mL) CDCl3 Procedure: adapted from Pavia, D. L.; Lampman, G. M.; Kritz, G. S.; Engel, R. G. Introduction to Laboratory Techniques, 4th Ed. Thomson Brooks/Cole: Mason, OH, 2006; pp 106-108. Fisher Esterification: In a microwave reaction vessel containing a microwave stirrer, combine your alcohol (20 mmol) and carboxylic acid (60 mmol). To this mixture, add 0.5 mL of concentrated sulfuric acid and immediately swirl the solution. (CAUTION: Do not reverse the order of this addition. Always add sulfuric acid to the solvent mixture to avoid splattering!) Secure the screw cap firmly over the top of the vessel (make sure your stirrer is inside!) and place your sample in the microwave rack – be sure to note your position. Your TF will then heat your reaction for 10 minutes under microwave irradiation. When the reaction is complete, allow the mixture to cool to room temperature. It is actually a good idea to either vent the vessel with a syringe needle or cool in an ice bath to make sure there is no sudden pressure release upon opening the vessel. Workup: Transfer your product mixture to a 15 mL Falcon tube and add 5 mL of water. Gently shake the tube and separate the biphasic mixture (which layer will contain your product?). Wash the organic layer with sodium bicarbonate solution (5 mL) and then with sodium chloride solution (5 mL). Transfer the organic layer to an Erlenmeyer flask and dry over sodium sulfate. Decant this solution into a 5 mL conical vial with a spin vane. Prepare a distillation apparatus according to the diagram shown below. Using a sand bath on a hot plate, distill your product ester by slowly heating the reaction. Use a metal thermometer to record the increase in temperature. Heat the product mixture to above 100 °C (note: many of these esters will boil much higher than this, so you may need to insulate your apparatus with cotton and continue heating higher). Collect about 1 mL of distillate and then remove it from the Hickman head with a pipet and discard. Continue collecting about 2 mL more distillate which you will save for characterization in a tare scintillation vial. Note the temperature at which your distillation is occurring and give this value in the analytical data section of your lab report (this should be a range, ie. 106-107 °C). After about 2 mL have been collected, cool your vial to room temperature (do not let it run dry!) and discard the contents. Analysis: Obtain a 1H and 13C NMR, IR, and GC/MS to fully characterize your data. Gently waft the ester towards your nose and record any characteristic smell. Finally, obtain a weight of your ester and record your yield. Pre-Lab Exercise: These questions do not need to be explicitly answered in writing, but you should be able to answer them prior to your arrival in lab. Some of these questions will form the basis for your lab report. 1. Why is microwave irradiation more favorable than conventional heating as a synthetic technique? 2. What changes in the IR spectrum would you observe by converting starting material to product? 3. During workup, what is the purpose of each of the following procedures: a) washing with sodium bicarbonate; b) washing with sodium chloride solution; c) adding sodium sulfate; and d) distillation? 4. How do you know when your product is distilling? 5. Why is it necessary to remove a small portion of the distillate first before collecting the bulk of the distilled product? 6. If your product was much higher boiling (>250 °C), how might you be able to distill the product quicker than conventional distillation? Post-Lab Assignment: Ask your instructor.