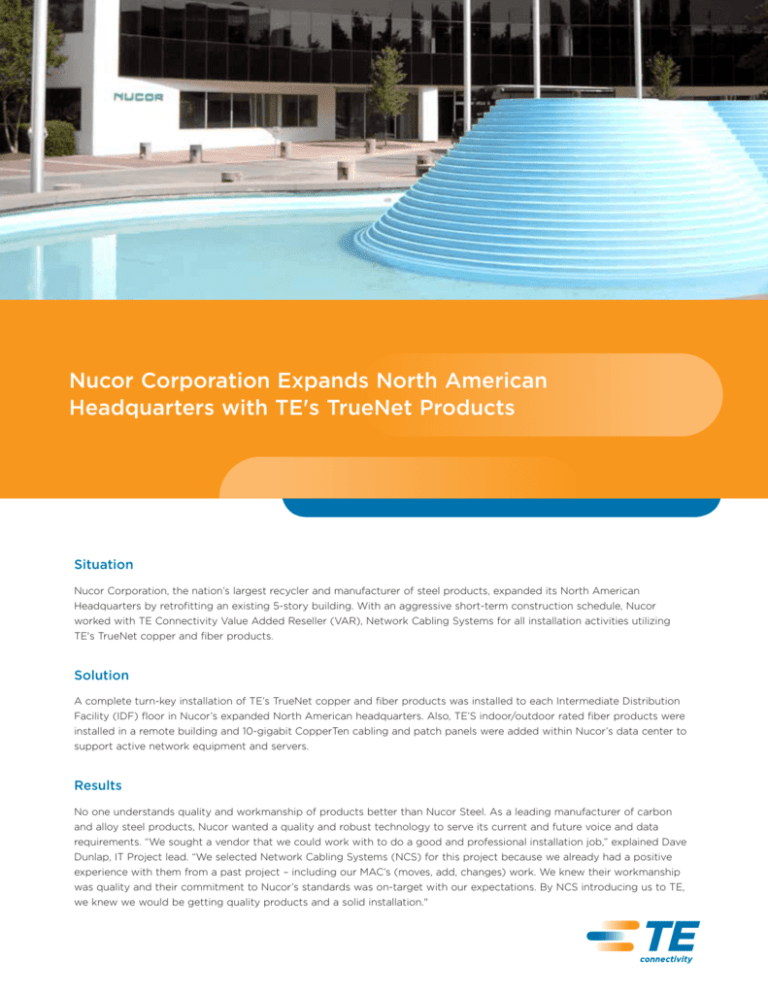

Nucor Corporation Expands North American

Headquarters with TE's TrueNet Products

Situation

Nucor Corporation, the nation’s largest recycler and manufacturer of steel products, expanded its North American

Headquarters by retrofitting an existing 5-story building. With an aggressive short-term construction schedule, Nucor

worked with TE Connectivity Value Added Reseller (VAR), Network Cabling Systems for all installation activities utilizing

TE's TrueNet copper and fiber products.

Solution

A complete turn-key installation of TE’s TrueNet copper and fiber products was installed to each Intermediate Distribution

Facility (IDF) floor in Nucor’s expanded North American headquarters. Also, TE’S indoor/outdoor rated fiber products were

installed in a remote building and 10-gigabit CopperTen cabling and patch panels were added within Nucor’s data center to

support active network equipment and servers.

Results

No one understands quality and workmanship of products better than Nucor Steel. As a leading manufacturer of carbon

and alloy steel products, Nucor wanted a quality and robust technology to serve its current and future voice and data

requirements. “We sought a vendor that we could work with to do a good and professional installation job,” explained Dave

Dunlap, IT Project lead. “We selected Network Cabling Systems (NCS) for this project because we already had a positive

experience with them from a past project – including our MAC’s (moves, add, changes) work. We knew their workmanship

was quality and their commitment to Nucor’s standards was on-target with our expectations. By NCS introducing us to TE,

we knew we would be getting quality products and a solid installation."

Situation

As a Fortune 500 company, Nucor operates in nineteen

states with its’ corporate headquarters located in Charlotte,

NC. Products produced are carbon and alloy steel for

commercial and residential use.

Nucor’s success can be attributed to the hard work and

dedication of its employees. Dating back to 1905, Nucor has

always been an innovator, producing the first commercial

cars with electric lights and electric starters. Known then as

an auto manufacturer, Ransom E. Olds, founded Oldsmobile

and then in 1905, REO Motor Car Company. Through a

series of acquisitions, the company evolved into the nuclear

instruments and electronics business and later purchased

a company that made steel joists and joist girders. The

company‘s remarkable evolution led to major innovations

in steel manufacturing. Not long thereafter, in 1972, the

company officially adopted the Nucor Corporation name.

Nucor has expanded its’ operations over the years and

in the summer of 2006, retrofitted a 5-story building for

expansion of its North American headquarters in Charlotte,

NC. It was an aggressive 6-month construction effort to

completely renovate the existing building. During this time,

Nucor’s IT department led a project to select a vendor that

could deliver professional results with the installation of the

building’s horizontal and riser cabling infrastructure. Through

a very detailed evaluation, including presentations from

Network Cabling Systems, all parties agreed that TE was

the solution that would best fill the requirements Nucor had

determined were essential.

Solution

TE Connectivity's TrueNet Category 6 AirES cable and

modular Category 6 jacks were installed to each floors’

workstation outlets. Two Category 6 plenum cables were

installed to each work location with each floors’ IDF

rooms being equipped with TE’s TrueNet patch panels.

For connectivity between each floor’s IDF, TE provided a

“bundled” Category 6 solution. The two 6-cable bundled

solution contained speed-wrap and aramid yarn for

additional strength and durability and was terminated in

each closet on TE’s TrueNet patch panels. In each IDF,

two equipment racks were each equipped with TE vertical

managers, three 8-inch managers for each rack. Each 8-inch

vertical manager was equipped with removable metal doors.

This provided not only the right aesthetics but also ensured

proper cable management within each IDF.

For vertical riser connectivity between the floors’ IDFs, a 50

micron multi-mode laser optimized 12-fiber TE cable was

installed. The cable with inter-locking armored sheathing

was terminated on TE’s TrueNet 2RU RMG series rack mount

enclosures in each of the floors’ IDFs. “We used TE’s RMG’s

fiber panels not only in the IDFs but also in our Data Center

and two other additional locations,” explained Dave Dunlap,

Nucor IT project lead, “as it is a low-profile design that is

modular and flexible for our needs. We chose to direct

terminate in each panel using SC couplers.”

In addition to providing horizontal and vertical cabling in

the new retrofitted building, Nucor also expanded their

network to a remote Generator building as well as a carrier/

equipment room using TE fiber cable. Two 12-fiber multimode (MM) indoor/outdoor plenum-rated fibers were

installed in conduit between the Nucor data center and the

generator building and another two 12-stranded MM fiber

cable was installed in the carrier/equipment room. “We

needed to provide connectivity to the generator room for

some time now and additional fiber was needed to expand

carrier services into our data center equipment distribution

area,” explained Dunlap. In both the carrier room and

generator building, a 2RU TE RMG fiber panel was installed

originating from the data center on a 4RU RMG fiber panel.

The fiber panels contain sliding and removable front and rear

panels which provide convenient access inside the panel. Up

to 72 terminations can be made in 1RU enclosure.

Inside the data center, TE’s TrueNet 10-gigabit cabling and

24-port CopperTen 1RU patch panels were installed to server

cabinets. Each server cabinet, approximately 15 cabinets

total, were equipped with TE’s CopperTen 24-port patch

panels. From each server cabinet, TE CopperTen cables were

extended to a centralized cabinet. The centralized cabinet,

also equipped with TE’s CopperTen panels, allows a single

TE's Copper and Fiber cabling running from the Main Distribution

Facility to the Intermediate Distribution Facilities.

Page 2

point for moves, add, changes without ever making any

patch changes in the individual server cabinets. “We wanted

an inter-connection between our switches and servers that

would provide us a single access point for any network

changes required. Now, if we need to make a network

change to any of our servers, we only do it in the centralized

cabinet,” said Dunlap. TE’s TrueNet high-performance patch

cords were used in the cabinets as well as the industries only

laser-tuned modular jacks in the patch panels. This ensures

that each jack manufactured is individually optimized for

10-gigabit performance.

The project also included voice and data expansion to

another floor of the newly renovated building. Nucor’s

affiliate, Castrip, currently occupies a portion of another

floor. Both fiber and Category 6 “bundled” cables were

extended to this floors IDF originating from the data center.

There were six total bundled cables each with six Category 6

cables. All cables were terminated on TrueNet patch panels.

The fiber was a 12-strand MM 50 micron cable with an

armored cable design using an all dielectric central strength

member (CSM).

A front view of one of the IDF’s with TE TrueNet patch panels

and 8" vertical managers with removable doors

Page 3

Results

Nucor Corporation emphasizes one goal, “Take Care of

our Customers.” They are committed to being the best in

the industry by providing the highest quality products and

having the most productive work-force possible. The key

to being such a profitable company today is attributed to

working together as a team committed to this one goal.

The North American headquarters expansion, allowed TE

and our partner, Network Cabling Systems, to be a part of

its exciting growth and to work with many talented Nucor

professionals. The challenges were many and at times, not

everything during the installation went as planned, however,

the end result was a very clean installation and a reliable

network infrastructure that will provide many years of highquality and consistent network performance. “We knew

we could count on NCS to provide a quality installation,”

concluded Scott Messenger, “and we are very happy with all

TE products that are in our network today.”

A rear view of the IDF rack with TE's CopperTen

cabling terminated and TE cable management

Case Study

Contact us:

Greensboro, NC

USA 27409-8420

Tel: 1-800-553-0938

Fax: 1-717-986-7406

www.te.com/EnterpriseNetworks

TE Connectivity, TE connectivity (logo), Tyco Electronics, AirES, CopperTen, TrueNet and TE (logo) are trademarks of the TE Connectivity

Ltd. family of companies and its licensors.

While TE Connectivity has made every reasonable effort to ensure the accuracy of the information in this document, TE Connectivity does

not guarantee that it is error-free, nor does TE Connectivity make any other representation, warranty or guarantee that the information is

accurate, correct, reliable or current. TE Connectivity reserves the right to make any adjustments to the information contained herein at

any time without notice. TE Connectivity expressly disclaims all implied warranties regarding the information contained herein, including,

but not limited to, any implied warranties of merchantability or fitness for a particular purpose. The dimensions in this document are

for reference purposes only and are subject to change without notice. Specifications are subject to change without notice. Consult

TE Connectivity for the latest dimensions and design specifications.

Tyco Electronics Corporation, a TE Connectivity Ltd. Company. All Rights Reserved.

104886AE 10/12 Revision © 2012, 2007