RefRigeRant REpoRT 18

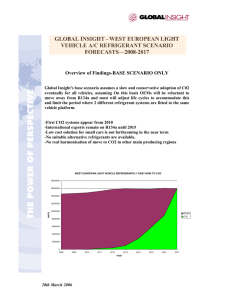

advertisement