R22 Phase Out Presentation

advertisement

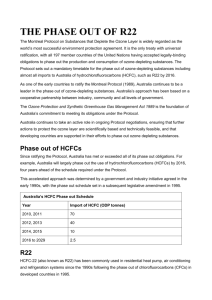

R22 Phase Out Presentation www.thermatic.co.uk Aims Aims To inform our customers of the single most important changes to the air conditioning industry in modern times Explain your options good and bad How it effects you as end users Dismiss some of rumours and scare mongering www.thermatic.co.uk Background to HCFC Phase Out When R22 is released into the atmosphere the ultraviolet rays from the sun cause it to decompose and chlorine is released into the stratosphere The chlorine then reacts with the ozone, reducing its quality and leads to ozone depletion in turn this allows harmful ultraviolet rays to reach the surface of the earth giving rise to both health and environmental issues In response to this, the international community signed the Montreal protocol to phase out ozone depletion materials by 2030. However in Europe the ban will take place at the end of this year The most harmful ozone – depleting substances such as C.F.C.S – R12 etc were banned in the 1990’s This lead to ‘less’ harmful ‘transitional’ refrigerant like R22 being banned between 2001-2004 depending on size www.thermatic.co.uk Background To HCFC Phase Out H.C.F.C – Hydrochlorofluorocarbon better known to us as R22 Refrigerant Commonly used in Air Conditioning systems until 2004, and is arguable one of the best performing refrigerants ever invented It is estimated that up to 20,000 systems could be still operating in the UK Question to ask yourself: Was the air conditioning in your premises installed before 2002? www.thermatic.co.uk When will R22 be banned? Recycled R22 will be banned after December 2014 Now’s the time to replace R22 systems R22 Replacement: Countdown to December 2014 www.thermatic.co.uk When will R22 be banned? www.thermatic.co.uk R22 Replacement: Likely customer impact R22 supply shortages and delays could impact on Normal operation of HVAC systems Routine Maintenance Compressor Repairs Refurbishment programmes Refrigerant replacement Energy efficiency of building operation www.thermatic.co.uk R22 Replacement Options Do Nothing Wait and See Risk of system failure Ageing system Increased running costs Higher Co² Emissions At some point you will have to change the system www.thermatic.co.uk R22 Replacement Options Retro Fit using Drop-in refrigerants Increased running costs High degradation of system components Reduced capacity Short term solution Comes with no manufacturer’s warranty Expensive to buy and Install www.thermatic.co.uk R22 Replacement Options Replace Removes the risk of having potentially redundant equipment after the end of this year New systems are highly efficient using the latest technologies therefore reducing fuel consumption – saving you money By removing R22 equipment you are reducing the risk of harmful chemicals destroying the ozone layer www.thermatic.co.uk R22 Replacement Options Modern Alternatives H.F.C (Hydrofluorocarbons) R407C, R410a etc all have zero ozone depleting potential (ODP) so offers a more environmentally friendly alternatives to CFCs and HCFCs The downside is HFC have medium to high G.W.P (Global warming potential) www.thermatic.co.uk R22 Replacement Options Natural Refrigerants Natural refrigerant are chemical which occur in natures BioChemical processes. Ammonia (R717) Carbon Dioxide (R744) Propone (Care 40) Etc These products were used as refrigerants prior to the 1950’s before Fluorocarbons became commonplace They do not deplete the ozone layer and make a negligible or zero contribution to global warming www.thermatic.co.uk F-Gas Regulation The European Union F-gas Regulation (No842/2006) became law on 4th July 2006 F-Gases such as R407c, R410a and R404a If you are handling, recovering, supplying, installing, manufacturing or own equipment containing HFC refrigerants in stationery equipment you now have legal obligations under F-Gas Regulations www.thermatic.co.uk F-Gas Regulation The objective of the regulation is to contain, prevent and thereby reduce emissions of Fluorinated greenhouse gases A leak of 1KG of refrigerant causes approximately the same environmental damage as driving a van. . . . . . . . . . 10,000 Miles www.thermatic.co.uk Leak Test Requirement Under F.Gas An annual ‘Non intrusive’ leak test for applications with 3KG or more (unless the equipment is hermetically sealed) 30KG or more ‘Non Intrusive’ leak test is required 6 monthly At least once every 3 months for applications with 300KG or more of F-Gases Leak detection systems must be fitted on applications with 300KG or more of F-Gases, and when these are in place, checking requirements are halved www.thermatic.co.uk Leak Test Requirement Under F.Gas A record of maintenance and servicing activity must be kept for each system If a leak is detected and repaired, a further check must be carried out one month to ensure that the repair has been effective In a word: Yes The law states if you are the legal operator (owner) of the air conditioning you are responsible www.thermatic.co.uk Leak Test Requirement Under F.Gas Records must be available on site for inspection and include quantity and type of FGas in each systems the amount of gas added or taken out, and the reason for this must be recorded along with any disposal information The identity and competence of personnel involved in the F Gas check should also be added and of course the dates of the test and results Penalties for either ‘operator’ or service provider failing to keep records may include enforcement/ prohibition notices www.thermatic.co.uk Q&A www.thermatic.co.uk