JSA GC-19 Site Painting

advertisement

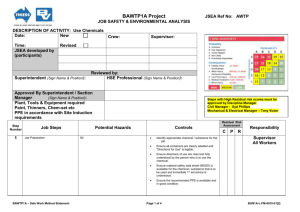

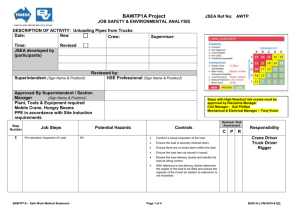

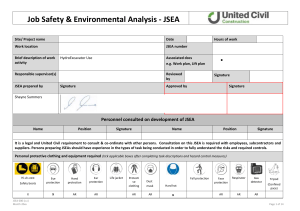

BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ Date: New Crew: Supervisor: Time: JSEA developed by (participants) Revised Reviewed by: HSE Professional (Sign Name & Position): Superintendent (Sign Name & Position): Approved By Superintendent / Section Manager (Sign Name & Position): Plant, Tools & Equipment required Step Number Job Steps Potential Hazards Controls Residual Risk Assessment C 1 2 Steps with High Residual risk scores must be approved by Discipline Manager Civil Manager - Syd Phillips Mechanical & Electrical Manager – Tony Victor Break the job down into steps. Each step should accomplish some major task and be in a logical sequence Site establishment / set up of area to be painted from work truck. Examine each to find possibilities that could lead top an accident Struck by other plant Site induction, wearing of hi vis clothing, isolate area if in a trafficable area by cones/bunting. Manual handling strains from unloading equipment from truck Two man lift for heavy equipment, use of vehicle loading crane for heavier equipment UV exposure causing sunburn / heat stress BAWTP1A – Safe Work Method Statement Identify the hazards associated with each step. P Responsibility R Specify what action/procedures will be taken to eliminate or minimise the hazards, the risk of injury/damage, and/or potential severity factors. Including the measure to be taken to ensure the proposed control Specify Person Responsible 1 D 1 Sup 1 C 4 Sup Use of sunscreen, hardhats to be worn, work under shade where available, have regular rest breaks depending on weather Page 1 of 6 BUN1A-L-FM-0010-01[2] BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ Set up site and equipment 4 Sup / Everyone 2 C 8 Operator 2 C 8 Sup/Operator 2 C 8 Sup/ Operator Plant item to be check by competent operator before operating. Maintenance to be conducted as per manufacture manual, faulty plant tagged out until repaired. Maintenance of muffler system / hearing PPE Eye damage to personal walking past the area of clean down. Area to be isolated if necessary and all personal on site to wear safety glasses as a site requirement. Slip trips and falls due to untidy area in which working. Unauthorised personnel entering work area Immediate work area barricaded. Erection of warning signage. 2 D 5 Sup/Operator Slip trips and falls from poor house clean by others 2 C 8 Sup Fall from heights / collapse of access equipment by us and others. Supervisor to inspect area of operation prior to commencement and liase with project management with regards to condition of the area to be access by our staff. *Scaffold to be used to access certain areas, scaffold not to entered unless scafftag is displayed as OK and passed. *Ladder access is only for access and not to be worked off, must be tied off at the top and well footed at the bottom. 2 C 8 2 C 8 Manual handling strain from pulling water hose up to a location for work at heights BAWTP1A – Safe Work Method Statement D 2 Plant failure causing injury to operator/bystander and noise from engine causing hearing loss Access to the areas to be cleaned and painted. 1 3 condition, drink fresh water in small amounts but often. Area to be checked before gaining access and leasing with site management regard area before starting. Correct foot ware to be worn and in the correct manner. Hose to be in area where it will not affect others and out of walkways. (to one side off if needed) JSEA #58 to be used in conjunction with this. Sup/Operator Operator Use of a rope to pull the hose up after the Page 2 of 6 BUN1A-L-FM-0010-01[2] BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ Mixing of painting. 5 Poisoning due to poor mixing and handling through skin contact. 6 Painting of Structural Steelwork. operator has gained a position suitable to pull the hose up without strain or effort / risk for injury. Use gloves while mixing at all time, safety glasses to be worn at all times. Coverall to be worn. Mixing to be as per manufacture data & MSDS instructions. Personal to be aware of information contained on there instructions and be available at all times for reference. JSEA #59 to be used here 2 C 8 Sup/Operator Poisoning from substance through contact. Use of gloves while painting and mixing, correct PPE as per manufacture data / MSDS sheet to be worn. Personal to be aware of information contained on these instructions and be available at all times for reference. Personal to carry paint in small amounts so not to strain or overbalance while working at heights. 2 C 8 Sup/Operator Personal being overcome by fumes from paint while applying. (Most of the work on this project is in open areas with plenty of ventilation) Personal working in open area with good ventilation. Personal wear “SUNSTROM” respirators at all times while painting in enclosed areas or poor ventilation. 2 C 8 Sup/Operator Environmental damage from spilling paint Paint will be in small container to reduce the risk of spills of large amounts. 2 C 8 Environmental spill kits to be available in the area of work. (Can be on the work truck as long as on site). Spills to be clean up as per MSDS with water and soap to break up and disperse. Wind direction and speed to be monitored. Paint to be applied by brush reducing the potential of combustible fumes. Fire extinguishers place around site and on support truck 2 2 C 8 C 8 Paint Over Spray Fire from paint fumes NOTE: If fire occurs, it is to be put out ASAP as it will give off toxic fumes if left to burn. Refer to MSDS for further information on fire fighting. BAWTP1A – Safe Work Method Statement Page 3 of 6 BUN1A-L-FM-0010-01[2] BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ Clean up after job Poisoning from substance through skin contact and splash into eyes. Use of gloves while cleaning up, correct PPE as per manufacture data / MSDS sheet to be worn. Contamination of the environment with empty containers. Ensure all tins have been catalysed and then placed in appropriate bins depending on local council requirements 7 2 C 8 2 C 8 Operator Sup 8 9 10 BAWTP1A – Safe Work Method Statement Page 4 of 6 BUN1A-L-FM-0010-01[2] BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ UNCONTROLLED ENERGY CREATES POTENTIAL – Have you considered each of the following Energy sources? (Tick to Indicate Each Energy Source You Have Considered & Controlled) Mechanical Electrical Falling objects Chemical Gasses/Liquid/Vapour Thermal Pressure Radiation Biological Points to Consider when Completing this JSEA: (this list is not inclusive – simply a prompt) Does a work procedure/ existing JSEA relate to this job? Have all relevant personnel been trained in the appropriate procedures? Do all relevant personnel hold the required competencies / authorisations required for the task(s)? – Have these been identified? Have all relevant parties been notified and included? Is signage required? Are there special PPE requirements? Is there an MSDS that needs to be referred to and made accessible? Is there a permit required for the job and is it available? Have all existing and recommended controls been noted on the above table and explained to those involved? Are any new hazards being introduced – if so, are they adequately controlled to ensure an acceptable level of risk is maintained? Are there any mechanical aids or special tools / equipment that need to be made available? Have the monitoring requirements been considered? Environmental Issues: Erosion and sediment controls/ chemical and oil spills/ fauna and flora/ dust/ noise/ vibration/ public complaints BAWTP1A – Safe Work Method Statement Page 5 of 6 Kinetic / Stored Solar Human Force Personnel participating in this job/task activity Name Signature Name Signature BUN1A-L-FM-0010-01[2] BAWTP1A Project JSEA Ref No: AWTP ______ JOB SAFETY & ENVIRONMENTAL ANALYSIS DESCRIPTION OF ACTIVITY: ______________________________________ QUALITATIVE MEASURES OF IMPACT – CONSEQUENCE LEVEL IMPACT 1 Insignificant 2 Minor 3 Moderate 4 Major 5 Catastrophic EXAMPLE OF CONSEQUENCE Minor Injury; low plant damage < $1,000; minor loss of productivity; no environmental impact Medical Treatment Injury / Restricted Work injury; plant damage < $100K; interruption to productivity; environmental release immediately contained Extensive injury (LTI), plant damage $100K - $500K; loss of productivity 1 to 5 days; loss of production; environmental release off site with no detrimental effects; Permanent Disability; plant damage $500K - $1M; loss of productivity >5 days; toxic environmental release off site with detrimental effect Fatality. Losses in excess of $1M. Permanent off–site contamination QUALITATIVE MEASURES OF LIKELIHOOD / PROBABILITY LEVEL A B C D E MEASURE Common Has Happened Could Happen Not likely Practically impossible DESCRIPTION The event is expected to occur in most circumstances Will probably occur in most circumstances GUIDE Once per week Might occur at some time Once per year Could occur at some time May occur only in exceptional circumstances Once per ten years Once per life of facility (10 – 30 years) Once per month H = High risk Immediate action required, activity must not start or be stopped if started. Highest level of Management needs to be involved. M = Medium risk Monitoring controls are required. Management responsibility must be specified. L = Low risk. Identify hazards and implement controls. Manage by routine processes. Ie inspections / observations BAWTP1A – Safe Work Method Statement Page 6 of 6 BUN1A-L-FM-0010-01[2]