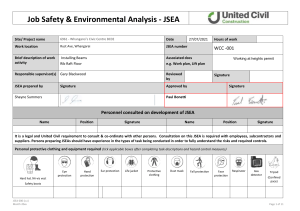

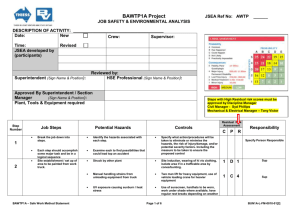

Job Safety & Environmental Analysis - JSEA Site/ Project name Date Work location JSEA number Brief description of work activity HydroExcavator Use Associated docs e.g. Work plan, Lift plan Responsible supervisor(s) JSEA prepared by Hours of work Reviewed by Signature Signature Approved by Signature Shayne Summers Personnel consulted on development of JSEA Name Position Signature Name Position Signature It is a legal and United Civil requirement to consult & co-ordinate with other persons. Consultation on this JSEA is required with employees, subcontractors and suppliers. Persons preparing JSEAs should have experience in the types of task being conducted in order to fully understand the risks and required controls. Personal protective clothing and equipment required (tick applicable boxes after completing task descriptions and hazard control measures) Hi-vis vest Safety boots Eye protection X X JSEA 000 (x.x) Month 20xx Hand protection AR Ear protection AR Life jacket Protecti ve clothing Dust mask AR AR Fall protection Face protection Respirator AR AR Gas detector Hard hat x Tripod (Confined pace) AR Page 1 of 14 Job Safety & Environmental Analysis - JSEA EMERGENCY RESPONSE Assembly / muster point: MSDS Powered plant and equipment to be used Emergency signal: Air Horn Chemicals to be used immediately available (Y/N) First aider: First aid kit location: In Truck Extinguisher location: In Truck 1. Spill kit location: In Truck Other: Insignificant Risk Matrix LIKELIHOOD Is expected to occur in most circumstances, occurs every month Moderate Major PEOPLE PEOPLE PEOPLE PEOPLE No treatment Pain & discomfort First aid treatment Medical Treatment (MTI). Lost Time Injury (LTI) Serious injury ENVIRONMENT On/Off Site release ENVIRONMENT On/Off Site release ENVIRONMENT ENVIRONMENT contained in controls Almost certain Minor cleaned up with internal resources Catastrophic PEOPLE Fatality(s) ENVIRONMENT On/Off Site release cleaned On/Off Site release with Toxic release on/off site up with specialist Major short term negative with detrimental long term assistance effects effects Damage to items of Major damage to items of ecological or culture ecological or culture significance significance Medium (8) High (13) Very High (20) Very High (23) Very High (25) Likely Will probably occur in most circumstances, occurs every 3 months Low (6) Medium (11) High (17) Very High (21) Very High (24) Possible Might occur at some time, every year Low (4) Medium (9) High (12) Very High (18) Very High (22) Unlikely Could occur at some time, known to happen in industry Low (2) Low (5) Medium (10) High (15) Very High (18) Rare May occur only in exceptional circumstances, no known experience Low (1) Low (3) Low (7) High (14) High (16) JSEA 000 (x.x) Month 20xx Page 2 of 14 Job Safety & Environmental Analysis - JSEA STEPS OF THE TASK POTENTIAL HAZARDS Break into sections of work What could go wrong at each step? What if? Job Setup Documentation Procedures Not Followed or misunderstood Potential Consequence UNCONTROLLED RISK 1 – 25 CONTROLS How do we control the hazard? What contingency plans if it goes wrong? Asset Damage Serious Harm 17 Maintenance Fluid injection while checking for leaks Personnel harm – trauma, sprains and strains Falling hazard JSEA 000 (x.x) Month 20xx RESIDUAL RISK 1 – 25 Risk Assessment / Project Safety Review Permits in place Undertake site induction Sign onto daily safety plan Report all events to management and operations Prestart checks to be completed (Refer Hydro-excavator Operating Procedures). SDS sheets available and held onsite Take 5 to reassess situation. Report all incidents/injuries to UCCL Supervisor Review general terrain and identified surface conditions. Look for ruts, larges rocks and uneven terrain. Check for leaks with engine off and operate all controls to relieve pressure. If system is pressurized, use cardboard- not your hand-to check for leaks. Wear PPE such as gloves and eye protection. Always use proper access systems provided when climbing onto equipment. Maintain three points of contact. Ensure all mud and debris is cleared on all access systems. WHO WILL DO IT? Be specific use names /titles e.g. ‘foreman’ 3 Operator Team Page 3 of 14 Job Safety & Environmental Analysis - JSEA Rotating or moving parts Perform all maintenance and repairs with engine off. Refuel and refill any liquids with engine off. Crushing Inhaling particles While working under tank or tank door, ensure cylinder locks are in place. On equipment with an over center tank door, ensure door is fully raised with lift arms locked. Use water spray and other means to control dust. Wear proper breathing protection. Combustion Confined space in the tank Traffic management Follow UCCL guidelines for entering confined spaces Arrange for traffic control. Working near traffic Refer TMP STMS Area preparation (for all areas) Unauthorised personnel Pedestrian/mobile plant interaction Personnel harm – trauma, sprains and strains Noise Clashes in work areas 25 Noise induced Hearing Loss Damage to reputation Damage to plant JSEA 000 (x.x) Month 20xx Hazard board and warning signs Spotter/Banksman If communication between workers is compromised work is to stop until corrected. Ensure vacuum truck vent is piped away. Ensure discharge point is down wind of the truck (potential ignition source) and will not blow back into the work area. The work area should be controlled during operation of the vacuum tanker. Operator Team 10 Page 4 of 14 Job Safety & Environmental Analysis - JSEA Damage to other assets Death Manual Handling Activities (for all areas) Sprains and Strains Items too heavy to lift Personnel harm – trauma, sprains and strains 17 Vacuum set up Static energy Damage to reputation Struck by Caught by Unauthorised personnel JSEA 000 (x.x) Month 20xx Personal Injuries No other contractors or works should be allowed within the work area. Barricade swing radius of Hydro Vac Hose. Barrier area only one point of access maintained to work area, warning signs in place PPE worn with available spares Spill kit available If needed - Set up gas detector and continuously monitor LEL at vacuum truck auxiliary engine. Rescue plan to be prepared and to include difficult rescue from elevated platform – if job is on elevated area Mark out the proposed excavation area. Then, arrange with B4UDIG or location service to have underground utilities located before digging. Warm up, stretch, use good lifting techniques Assess load and placement Rotate workers Hand and body position Lifting hydro-excavator hoses is to be undertaken with two men. Gain assistance, multi person lift, use mechanical aids Park vacuum truck in a safe area, adjacent and up wind of the area. Be aware of vacuum truck discharge and possible effects on other people, since high volumes of 2 Team 10 Team Page 5 of 14 Job Safety & Environmental Analysis - JSEA Asset damage Slip trip fall Sprain and strain injuries Damage to plant Damage to other assets Loss of containment 25 Death JSEA 000 (x.x) Month 20xx vapour could be emitted from the truck vent Earth leads connected to approved positive earth boss Use anti-static earth bonded hoses Hose routing away from access area Connect venting pipe discharges away from area. Communicate activity with other teams in the area Hand and body position, two person lifts to be used when position larger hoses Double check all hose connections and tie hose to handrail. The vacuum pump discharge should pass through a water scrubber (part of truck mounted equipment) to reduce particulate emissions. The vacuum tanker and vessels must be bonded together and earthed to prevent static discharge and potential ignition source. Use only bonded hoses and Aluminum fittings. All hoses to be tested, tagged and verified. During the removal process hazardous/flammable vapors could be emitted to atmosphere. All sources of ignition must be eliminated from the working area Page 6 of 14 Job Safety & Environmental Analysis - JSEA Hydro Excavate Cave-in protection • Identify all asset utilities with a Cable Locator in area to be Excavated. Mark with a visible indicator that can be easily seen by employees in the work zone. Safe access and egress • Complete UCCL Excavation Permit Hazardous Atmospheres • Barricade swing radius of Hydro Vac Hose Underground Interferences Struck by/Crushed by • Sloping, benching or shoring as required by excavation permit • Competent person to verify daily integrity of excavation per excavation permit • Install ladders per policy. Inspect before use or install ramps per excavation policy • Use of a calibrated 4-gas monitor as needed per excavation permit. JSEA 000 (x.x) Month 20xx Page 7 of 14 Job Safety & Environmental Analysis - JSEA Start “Digging” Hydro Excavating Contacting unknown underground (asset) lines that are not marked Explosion, Fire, Electrical Shock/Electroc ution Verify utilities locates. Wear proper PPE, such as electrically insulated boots and gloves, when within 4m of an electric line. Use proper rotating nozzle and pressure for the type of utility that will be exposed. Maintain adequate distance from existing utility. Keep water lance in motion while excavating. Know emergency procedures. STOP WORK”, re-evaluate job steps and if Electrical Lines are identified incorporate equal potential grounding mats (EPM’s) • Maintain a circular motion with the pressure wand until the service has been “Day lighted”. Then use a sweeping motion across line, never allowing pressure wand to become stationary and avoiding contact with line. JSEA 000 (x.x) Month 20xx Page 8 of 14 Job Safety & Environmental Analysis - JSEA Potholing near or around existing utilities Striking existing utility Striking gas line Verify utilities locates. Wear proper PPE, such as electrically insulated boots and gloves, when within 10 foot of an electric line. Use proper rotating nozzle and pressure for the type of utility that will be exposed. Maintain adequate distance from existing utility Keep water lance in motion while excavating. Know emergency procedures Immediately shut off engine and remove any ignition sources if can be done safe and quickly. Know emergency procedures. • In the event of a gas line strike: o Immediately shut off engine and remove any ignition sources (if can be done safe and quickly.) o Warn others that a gas line has been cut and that they should leave the area. This may include nearby homes or buildings. If jobsite is along a street, stop traffic. o Leave jobsite as quickly as possible. Immediately call your local emergency phone number and utility company. JSEA 000 (x.x) Month 20xx Page 9 of 14 Job Safety & Environmental Analysis - JSEA o Do not return until given permission by emergency personnel and utility company. Striking existing electric line Wear electrically insulated boots and gloves whenever exposing an electric line. Know emergency procedures. • In the event of an electric line strike: o Release trigger control to break contact. o Utilize small shuffle steps to leave the area. o Warn others nearby that an electric strike has occurred and vacate the area. o Contact the utility company o Do not resume work or allow anyone into area until given permission by the electric company. Striking existing fiber optic cable Know emergency procedures. • In the event of a fiber optic cable strike: o Do not look at cut ends. o Contact utility company immediately JSEA 000 (x.x) Month 20xx Page 10 of 14 Job Safety & Environmental Analysis - JSEA Operating the vacuum excavator Crushing injury Chemical reaction Suction injury Struck by debris when clearing hose Reverse flow Flying debris Raising tank & Boom operation Electrocution - Striking overhead energized lines JSEA 000 (x.x) Month 20xx Keep all bystanders away. Before operating the vacuum excavator, make sure to be familiar with all controls and functions. Maintain in line of sight to any moving components such as the debris tank door, debris tank, and boom. Follow proper procedures in the operator's manual. Know what you are vacuuming and what may already be in the tank. Keep suction hose away from face and body parts. Shut off the engine to correct the clogged hose. Never open any component when the unit is operating in reverse flow. Switch to vacuum or shut off engine before opening any system component. Keep unit in “vacuum” mode unless pressure is needed. Restrain hose prior to pressurization. Do not use pressure to clear clogs in vacuum hose. Always identify all overhead power lines prior to the start of excavation. Always stay away from overhead electric lines while operating raised equipment or boom. Follow regulations for working around overhead power lines. If voltage is unknown, equipment must be kept at least 20 feet away Page 11 of 14 Job Safety & Environmental Analysis - JSEA Disposal JSEA 000 (x.x) Month 20xx Disposal of spoils from energized powerlines. Assume all electrical lines are energized and uninsulated. If you must work near overhead energized lines: De-energize lines if possible. Make sure required distance is maintained. Have a spotter to ensure required distance is maintained. Meet with all required personnel at the jobsite and ensure to review the location of the powerlines and precautions to take as well as the areas to avoid. • Regulations for disposal of spoil tank contents vary from job to job. • Some jobs do not allow excavated soil to be placed back into the excavation if it has been mixed with water. • Only dispose contents in approved locations. Page 12 of 14 Job Safety & Environmental Analysis - JSEA MINOR TASK CHANGE Steps of the task Break into sections of work DATE POTENTIAL HAZARDS What could go wrong at each step? What if? UN- ELIMINATE (E) CONTROLLED SUBSTITUTION (S) RISK 1 – 25 ENGINEERING CONTROLS (EC) CONTROLS How do we control the hazard? What contingency plans if it goes wrong? RESIDUAL RISK 1 – 25 WHO WILL DO IT? Be specific use names /titles e.g. ‘foreman’ ADMINISTRATI VE CONTROLS (AC) PPE Name: Signature: Date: Workers must always be given the opportunity to comment and make suggestions to improve controls. Use visual aids (e.g. drawings, photos) or complete in work areas wherever possible. Brief in small working teams to encourage them to speak up if they don’t understand. Record any changes to the JSA (handwrite) and have each worker sign below. JSEA 000 (x.x) Month 20xx Page 13 of 14 Job Safety & Environmental Analysis - JSEA Person responsible for explaining this JSEA must have experience in the types of task being conducted in order to fully communicate the risks and required controls. Name JSEA 000 (x.x) Month 20xx Signature Date Employer Page 14 of 14