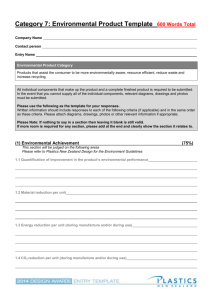

Tomasz Brodzicki

advertisement