ENG514

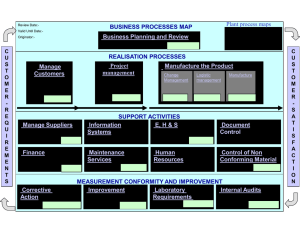

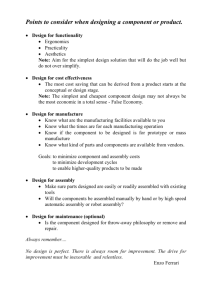

advertisement

MODULE SPECIFICATION FORM Module Title: Design for Manufacture Module code: (if known) ENG514 Existing/New: New Level: Semester(s) in which to be offered: Title of module being replaced (if any): Originating Subject: Engineering Module duration (contact hours/ directed private study: 60 hrs contact/dps + 140 hrs private study 1 and 2 Credit Value: With effect from: 20 Sept 2010 Design for Manufacture Module Leader: S. Byrne Status: core/option/elective (identify programme where appropriate): Percentage taught by Subjects other than originating Subject (please name other Subjects): Programme(s) in which to be offered: HND Electrical & Electronic Technology HND Mechanical Technology 5 Pre-requisites per programme (between levels): Option 0% Co-requisites per programme (within a level): Module Aims: Develop knowledge of manufacturing techniques such as Manufacturing Technology, Design, Quality Assurance, Robotics and CADCAM. Cost benefit analysis will be used in considering design options. Expected Learning Outcomes Knowledge and Understanding: At the end of this module the student should be able to: 1. Design a product that may be manufactured to be commercially viable 2. Use CADCAM software effectively in the design process Transferable/Key Skills and other attributes: Managing self Problem solving Numeracy Working with others Use of software packages Assessment: please indicate the type(s) of assessment (eg examination, oral, coursework, project) and the weighting of each (%). Details of indicative assessment should also be included. Assessment number (use as appropriate) Assessment One: Type of assessment Manufacturing design project including tolerancing and computer-aided software for such as a powered lawnmower Weighting Duration (if exam) 100% Word count (if coursework) 3000 Learning and Teaching Strategies: Delivery will be by a series of interactive classes using project-based design exercises and case studies with occasional note-based lectures. The learning element will be evaluated by carrying out the assessment laid out above which will ensure the learner has the opportunity to achieve all the stipulated outcomes. Although specified to be stand-alone, this module may be integrated with other relevant modules (listed in Aims) for delivery. Syllabus outline: 1. Economic Manufacture Manufacturing methods: selection of methods, key design factors:- design form, materials type and properties, quality requirements, available equipment, processing capability, costs, labour skills. Analysis of methods, design criteria, decision criteria (which, why, alternatives, suitability). Total Costs: material, labour, overheads; fixed and variable costs; relationships of manufactuing method, complexity of design form, surface finish, relative cost. Break-even analysis. Standardisation: BS/ISO/industry-specific standards relevant to design form/materials; standard components/parts/fittings; preferred number methods for detection and standardisation; cost advantages of standard parts (design, development, tooling, plannng, choice, labour); ease of replacement, interchangeability. Advantages and disadvantages. Process requirements: factors affecting material requirements:- form, size, weight, processing method, quality, quantity, availability, service life, characteristics (mech., elect., chemical). 2. Economic Assembly Appropriate Mecthod: analytical (questioning) approach to select method. 'Value Engineering' approach: evaluate specification, validity of product; minimise variation between similar components, sequencing of assembly stages; symmetrical and asymmetrical parts; justify number of components used; suitability for automatic feed and assembly (FMS and robots), unidirectional component location, ease of handling, positioning, stacking, accessibility within assembly. Features of good design: location of spigots, flanges, tenons; locating faces; accessibility, alignment, families of parts (groupings). 3. Tolerances and Dimensions Principles: Geometrical tolerancing:- description and application for components, sub-assemblies, assemblies. Tolerance build-up. Use of BS, ISO standards. Design, manufacture, inspection. 4. Computer-aided Manufacture Software: Numerical control of assembly. Material selection. Bibliography Recommended Reading: Needham P. M. Design for Manufacture (2008) Corbett J, Dooner M, Meleka J, Pym C; Design for Manufacture; (Addison-Wesley, 2001).