Table of Contents - Access Florida Tech

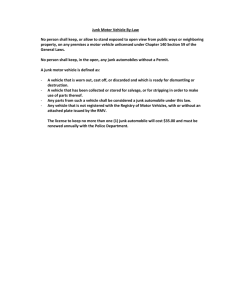

advertisement