woodchip - SOUTHERN Railfan

advertisement

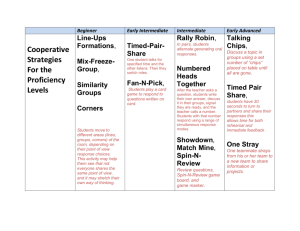

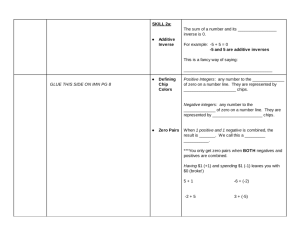

1 Southern's wood-chip cars-Iike this one loaded and ready to roll at St. Regis Paper Company's chipping plant at Fargo, Ga.-save money for shipper and railroad in handling this commodity. 2 Overhead conveyor at St. Regis plant at Fargo can load three cars at once. Note angle-iron bracing in the cars. First of their kind. That's what Southern can say about its high-capacity, lightweight freight cars specifically designed to carry wood chips to pulp and paper manufacturing plants. This light and bulky commodity is now being handled efficiently for the first time in cars with a cubic capacity to match shippers' needs for high- volume, low-cost transportation. Southern designed the car because of the increasing use of wood chips as a raw material for pulp and paper manufacturing. For years these manufacturers brought raw material into their plants only as pulpwood logs. Now a number of mills move part of their wood in chip form. The wood-chip experiment started as a means of salvaging sawmill waste slabs ( and making the available timber supply go further). It worked so well that some manufacturers now chip part of their pulpwood logs before moving them to the plant. At first railroads carried wood chips in standard 70-ton hopper cars. To be economical, wood chips have to move at a low freight rate. But they are so light and bulky that an ordinary hopper car won't hold enough to let a railroad break even on the haul. As volume increased, railroads experimented with makeshifts-such as increasing the height of the hopper car body with metal extensions-to put larger loads in the modified standard car. Southern operating people soon realized, however, that the answer had to be a car designed with wood chips in mind. For a year and a half operating officers studied the wood-chip business throughout the U .S. and Canada, with particular emphasis on loading, unloading and transportation. The railway wore out carload after carload of wood chips in experimenting with the design of the car and a mechanical device to unload it rapidly and efficiently. To construct a car with a lightweight body and large cubic capacity, advantage was taken of the loading characteristics of the commodity. It was learned that a load of wood chips clings together, will stand vertically with little or no support and exerts hardly any pressure on the sides of the car . The result? A practical wood-chip car unlike any- thing else on rails, except in its standard under frame and trucks with roller bearings. The open-top car body is high (16 1/4 feet above rail top) , 54 feet long inside and constructed of thingauge steel cross braced with angle irons. The car floor, which slopes slightly from sides to center, is of perforated steel to allow for drainage and to reduce weight. 3 Unloading wood-chip cars at St. Regis Paper Company's Jacksonville, Fla., paper mill. Each car is spotted in turn beside the Southern-designed mechanical unloader (half hidden beneath the steel beam that helps support a car shaker). When hopper cars are unloaded on this track, the shaker (in white circle) grips the car top and shakes the car to loosen the load. Southern's car was designed to stay out of its damaging clutches. 4 Inside-the-car view of the mechanical unloader at work. The movable blade rakes ships out the side door opening and into a pit beneath the track. The steel-mesh blade in the foreground, with a rubber strip on the lower edge, is attached to the unloader blade to sweep the last of the chips from the car. Two doors make up the lower part of each side of the car. Any number of these four doors can be quickly and easily raised to open the car for Unloading. The Southern-designed unloading machine travels along a heavy beam support beside the unloading track. It mounts a movable blade that angles through a load of chips like a plow turning earth and rakes them into a pit below the track. From there a conveyor carries the chips into the mill. This side-door method of unloading empties the car rapidly without the need for car shaking devices (often required to remove a load that doesn't fall freely through the bottom doors of a hopper car) . 5 Showing the characteristics of a wood-chip load that made possible the thin gauge metal sides of the wood-chip car. A load of chips virtually stands alone, exerts hardly any pressure on the sides of the car. 6 Close-up of the unloader at work, with the steel mesh blade attached to clear the last of a load of chips from the car. 7 Normally, one door at a time is raised to open the wood-chip car for unloading. However, it is just as simple to open all four doors at once. . , Ultimately, a car shaker will damage even a heavily- built car. Southern's car carries 21/2 times as much chipped wood as a 70-ton hopper. Normally unloaded in less than a half-hour, the car can actually be emptied faster than the pit conveyor will clear away the chips. A shipper's cost for switching and in-plant hand- ling-as well as the railways cost in moving the car-amounts to much the same for one of these high- volume cars as for a 70-ton hopper. When two cars carry the same amount of chips that used to move in five, everybody saves money. And Southern has further shared the benefits with shippers by establishing rates intended to encourage full use of these cars. Wood-chip freight rates are applied on the basis of units of 190 cubic feet of volume. A 70-ton hopper car loads 14 such units. Southern's car will hold 35 units. Up to 25 units the usual freight rate applies. On any amount over that, Southern allows a discount of 20 per cent. Southern designed cars of varying dimensions in the search for the car best suited to wood-chip loading. A number of these are still being used. But the car 54 feet long, 11 feet wide and 16 1/4 feet above rail top is Southern's standard. The railway's work in designing the car promises to keep on paying off handsomely for all concerned. -Paper and pulp manufacturers can ship raw materials in a convenient form, with reduced transportation costs and substantial economies in switching and plant handling of cars. -Southern can make low-rated wood-chip traffic pay its way. -The cause of conservation is served, since any sawmill waste productively used saves some standing timber. Southern's wood-chip car is more than a freight car. It is one more example of what imaginative thinking in Southern's operation is doing for the shipper, for the railroad and railway people, and for the territory we serve in making available the full benefits of low-cost mass transportation. ... 9 A line of Southern wood-chip cars on the unloading track at St. Regis Paper Company's Jacksonville plant. In the foreground is a stack of pulpwood logs, the more familiar form in which wood is shipped as a raw material for pulp and paper.