04.01-A Content Outline

advertisement

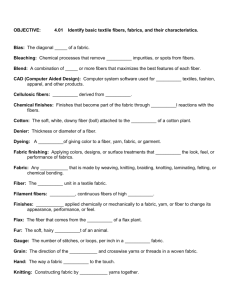

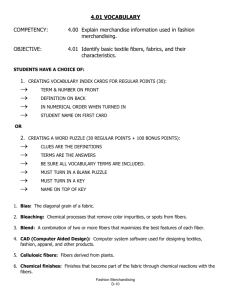

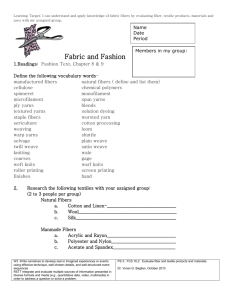

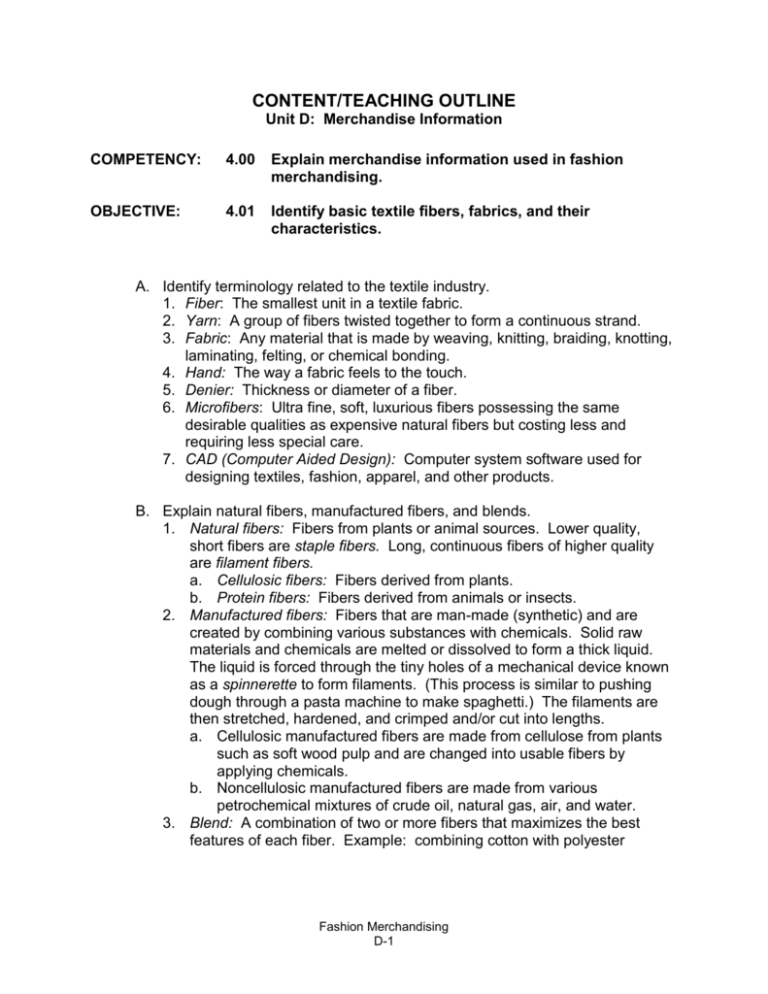

CONTENT/TEACHING OUTLINE Unit D: Merchandise Information COMPETENCY: 4.00 Explain merchandise information used in fashion merchandising. OBJECTIVE: 4.01 Identify basic textile fibers, fabrics, and their characteristics. A. Identify terminology related to the textile industry. 1. Fiber: The smallest unit in a textile fabric. 2. Yarn: A group of fibers twisted together to form a continuous strand. 3. Fabric: Any material that is made by weaving, knitting, braiding, knotting, laminating, felting, or chemical bonding. 4. Hand: The way a fabric feels to the touch. 5. Denier: Thickness or diameter of a fiber. 6. Microfibers: Ultra fine, soft, luxurious fibers possessing the same desirable qualities as expensive natural fibers but costing less and requiring less special care. 7. CAD (Computer Aided Design): Computer system software used for designing textiles, fashion, apparel, and other products. B. Explain natural fibers, manufactured fibers, and blends. 1. Natural fibers: Fibers from plants or animal sources. Lower quality, short fibers are staple fibers. Long, continuous fibers of higher quality are filament fibers. a. Cellulosic fibers: Fibers derived from plants. b. Protein fibers: Fibers derived from animals or insects. 2. Manufactured fibers: Fibers that are man-made (synthetic) and are created by combining various substances with chemicals. Solid raw materials and chemicals are melted or dissolved to form a thick liquid. The liquid is forced through the tiny holes of a mechanical device known as a spinnerette to form filaments. (This process is similar to pushing dough through a pasta machine to make spaghetti.) The filaments are then stretched, hardened, and crimped and/or cut into lengths. a. Cellulosic manufactured fibers are made from cellulose from plants such as soft wood pulp and are changed into usable fibers by applying chemicals. b. Noncellulosic manufactured fibers are made from various petrochemical mixtures of crude oil, natural gas, air, and water. 3. Blend: A combination of two or more fibers that maximizes the best features of each fiber. Example: combining cotton with polyester Fashion Merchandising D-1 C. Identify basic natural fibers, their characteristics, care, and uses. 1. Cotton: The soft, white, downy fiber (boll) attached to the seed of a cotton plant. Cotton, grown in the southern United States and other warm climates, is the most widely used of all natural fibers. a. Characteristics (1) Strong and durable (2) Absorbent (3) Cool to wear (4) Shrinks in hot water (5) Wrinkles easily b. Proper care (1) Machine wash (2) Tumble dry at moderate temperatures (3) Press with warm to hot iron (depending on fabric weight) c. Some common uses (1) Underwear (2) Socks (3) Shirts, blouses (4) Jeans (5) Sheets, towels (6) Slip covers 2. Wool: The fiber that forms the coat (fleece) of sheep. The primary sources are Australia, South America, New Zealand, and United Kingdom. a. Characteristics (1) Natural insulator; warmest of all natural fibers (2) Soft and resilient (3) Naturally flame retardant (4) Absorbs moisture more slowly than cotton (5) Will shrink if machine washed or dried unless chemically treated (6) Affected by moths b. Proper care for untreated wool (1) Dry clean or hand wash in cool water and a mild detergent (according to garment label) (2) Do not place in dryer (3) Press with cool iron c. Some common uses (1) Sweaters, tailored suits (2) Coats (3) Blankets (4) Upholstery (5) Rugs, carpets 3. Flax: The fiber that comes from the stem of a flax plant. Linen is made by weaving or knitting flax fiber into fabric. Flax is primarily grown and harvested in Eastern Europe. Fashion Merchandising D-2 a. Characteristics (1) Durable and strong (2) Lustrous and smooth (3) Comfortable and cool to wear (4) Wrinkles easily (5) Creases difficult to remove (6) Can be expensive b. Proper care (1) Hand wash or dry clean (according to garment label) (2) Iron while damp c. Some common uses (1) Pants (2) Blazers (3) Tablecloths, napkins (4) Upholstery 4. Silk: The fine, lustrous fiber that comes from a cocoon spun by a silkworm. The silkworm forces two fine streams of a thick liquid out of tiny openings in its head. These streams harden into filaments or fibers upon contact with the air. Silk is primarily produced in Asia (especially Thailand, China, India), and Madagascar. a. Characteristics (1) Luxurious appearance and feel (2) Strongest of all natural fibers (3) Drapes nicely (4) Expensive (5) Easily spots if fabric becomes wet (6) Weakens with exposure to sun and perspiration b. Proper care (1) Dry clean or hand wash (according to garment directions) (2) Press on wrong side with warm iron c. Some common uses (1) Wedding gowns (2) Lingerie (3) Men’s ties (4) Tailored garments (of raw silk) (5) Home furnishings (raw silk) 5. Other natural fibers (provided for name recognition) a. Ramie b. Jute, hemp, raffia, sisal c. Down d. Camel hair, angora, mohair, cashmere, alpaca D. Explain the common sources of leather and fur. 1. Leather: A tough, flexible material made by preserving animal hides through a process called tanning. a. Tanning converts the hides into finished usable leather. Fashion Merchandising D-3 b. Leather is used for handbags, shoes, belts, and jackets. c. Suede: Leather with a napped surface on the flesh side. d. Since leather is a by-product of the meat industry, the public generally does not protest the use of leather for apparel and accessories. e. Primary sources (1) Cattle (mostly from the Americas, Africa, and Europe) (2) Goatskins (India and China) (3) Sheepskins (Australia) (4) Reptiles – lizards, snakes, alligators (Asia) 2. Fur: The soft, hairy coat of an animal. a. Fur is used for coats, outerwear, and trimmings. b. Fur is not a by-product of the meat industry. Because animals are bred or trapped specifically to harvest their fur, there are groups that publicly protest the use of animal fur for fashionable clothing.) c. Primary sources (1) Mink (Scandinavia, United States, Holland, and Russia) (2) Chinchilla (3) Fox (4) Rabbit (5) Sable (Russia and Canada) E. Identify basic manufactured fibers, their characteristics, and common uses. 1. Polyester a. Made from coal or petroleum b. Strong and often blended with other fibers c. Resistant to wrinkling d. Shrink and stretch resistant e. Easy to care for f. Great washability g. Pills easily h. Static buildup i. Some common uses: children’s wear, shirts, suits 2. Nylon (first fiber to be manufactured totally from chemicals) a. Strong, durable, elastic b. Dries quickly c. Resists wrinkles and soil d. Washes easily e. Heat sensitive f. Clings to the wearer g. Some common uses: hosiery, swimwear, windbreakers 3. Acrylic a. Resembles wool b. Soft and warm c. Bulky, yet lightweight d. Quick drying Fashion Merchandising D-4 e. f. g. h. i. Strong Wrinkle resistant Static buildup Pills easily Some common uses: terrycloth, bathrobes, knitted garments, outdoor furniture fabrics and awnings 4. Rayon a. Soft, absorbent, and comfortable b. Inexpensive c. Stretches and is weak when wet d. Mildews and wrinkles easily e. Some common uses: linings, sports shirts, jackets 5. Acetate a. Very versatile b. Inexpensive and easy to dye c. Silky, luxurious d. Deep luster, soft e. Wrinkles easily f. Special care needed in cleaning g. Common uses: neckties, lingerie, blouses, linings 6. Spandex a. Known for its ability to stretch b. Soft, lightweight c. Durable d. Resistant to lotions, oils, sun, and perspiration e. Nonabsorbent f. Easily damaged by chlorine bleach g. Some common uses: swimwear, dancewear, exercise wear F. Describe the steps involved in fabric production. 1. Fibers are usually twisted together and spun into yarns. 2. Yarns are either woven or knitted to form fabric. 3. Color is added by dyeing or printing to enhance the fabric’s appeal. 4. A finish is applied to make the fabric suitable for its end use and to improve its appearance. (See Section H for discussion and the glossary for a definition of finishes.) G. Identify the common ways to turn yarn into fabric. 1. Weaving: The process of interlacing one or more sets of yarns at right angles on a loom. a. Warp yarns: Yarns that run lengthwise in woven fabric. b. Weft yarns: Yarns that run crosswise in woven fabric. c. Grain: The direction of the lengthwise and crosswise yarns or threads in a woven fabric. d. Bias: The diagonal grain of a fabric. The bias provides the greatest “give” or stretch in the fabric. Fashion Merchandising D-5 e. Common weaves (1) Plain weave: The simplest weave in which the weft (crosswise) yarn is passed over then under each warp (lengthwise) yarn. A basket weave is one variation, with the weft yarn passing over two and under two warp yarns each pass. Examples: chiffon, seersucker, taffeta (2) Twill weave: A weave in which the weft yarn is passed over and under one, two, or three warp yarns beginning one warp yarn back on each new row. Used for durability, this weave produces a diagonal design on the surface. Examples: denim, gabardine (3) Satin weave: A weave that produces a smooth, shiny-surfaced fabric resulting from passing the weft yarn over and under numerous warp yarns to create long floats. Examples: sateen, satin f. Other weaves (provided for name recognition) (1) Pile weave – Examples: corduroy, velvet (2) Dobby – Examples: dotted swiss, pique (3) Jacquard – Examples: brocade, damask (4) Leno – fabrics with an open, lacy appearance 2. Knitting: Constructing fabric by looping yarns together. a. Weft knits: Knits made with only one yarn that runs crosswise forming a horizontal row of interlocking loops. (1) Cut edges will curl. (2) Weft knits run if snagged. (3) Examples: jersey, ribbed knits, sweater knits b. Warp knits: Knits made with several yarns creating loops that interlock in the lengthwise direction. (1) Do not ravel (2) Have selvage edges (3) Examples: tricot, raschel knits c. Gauge: The number of stitches, or loops, per inch in a knitted fabric. 3. Other fabric constructions a. Nonwoven fabrics. Fibers are compacted together using moisture, heat, chemicals, friction, or pressure. Examples: quilt batting, garment interfacings, felt, artificial suedes b. Laces and nets. Made by knotting, twisting, or looping yarns. Example: lace c. Braided fabric. Created by interlacing three or more yarns to form a regular diagonal pattern down the length of the resulting cord. Examples: decorative trims, shoelaces d. Bonded fabric. Made by permanently fastening together two layers of fabric by lamination. Examples: two fabrics bonded so that one serves as a self-lining as in skiwear or winter coats e. Quilted fabric. A layer of padding or batting is sandwiched between two layers of fabric and held in place by stitching. Examples of use: bedspreads, placemats, and outerwear Fashion Merchandising D-6 H. Discuss fabric finishing. 1. Fabric finishing: Applying colors, designs, or surface treatments that change the look, feel, or performance of fabrics. 2. Bleaching: Chemical processes that remove color, impurities, or spots from fibers. 3. Dyeing: A method of giving color to a fiber, yarn, fabric, or garment. 4. Printing: The process of adding color, pattern, or design to the surface of fabrics. 5. Finish categories a. Mechanical: Finishes that are applied mechanically rather than chemically. These finishes affect size and appearance. Examples: glazing, embossing, brushing/napping/cutting (corduroy) b. Chemical: Finishes that become part of the fabric through chemical reactions with the fibers. These finishes affect performance. Examples: Flame retardant, stain resistant (Scotchgard®), waterproof, permanent press, preshrunk (Sanforized®) I. Explain current trends and technology in the textile industry. 1. Equipment and machinery continues to change the industry. Machinery continues to be more productive, processes are constantly monitored by computer systems, and product quality is expected to improve. a. Weaving and knitting machines are becoming more automated. Most sewing operations require an operator. b. Color management tools are necessary to synchronize a colored design on a computer screen with a paper printout and the actual fabric color. c. Computer Aided Design tools are becoming more sophisticated with 3D capabilities. 2. Microfibers. New microfibers will enhance the characteristics of high performance fabrics for wicking (a fiber’s ability to draw moisture away from the body), coolness, warmth, and protection resulting in the production of intelligent garments. 3. Development of new recycling processes. Plastic soda bottles are converted into a polyester fiber that is used to make fabric for t-shirts and filling for pillows. The fiber can be recycled numerous times without losing its performance attributes. 4. Nonwoven fabrics are finding increasing usage in reusable apparel and other products, thus replacing the traditional knits and wovens. a. Nonwovens are widely used as interlinings in blouses, jackets, shirts, and waistbands. b. Nonwovens have been introduced into the outdoor sporting markets for fishing and hunting apparel. c. Medical textiles are being constructed as reusable but with special barrier materials to protect the surgeon and those in the operating room. Fashion Merchandising D-7 5. 6. 7. 8. 9. d. Tops (blouses) using a printed nonwoven fabric are in the marketplace. e. Nonwovens may also be found in the SPF garments (garments that allow you to tan through the fabric at a controlled rate). Individuality. Consumers have more and more choices when they go to shop for clothing. Individuality in clothing choices continues to advance the demand for mass-customization in clothing. a. In most malls customers can find a store that will print a custom design on a T-shirt or embroider a customized design on a cap. b. Land’s End or L.L. Bean will monogram initials on a garment. c. Brooks Brothers and Hart Schaffner and Marks handle orders for custom-made shirts or suits. d. Mass customization is prevalent in the uniform sector where logos and names are embroidered or printed on garments. Examples: Federal Express, Postal Service, football teams Demand for new technologies for developing new, improved textile products a. Protection for those who face hazardous environments (fire, comfort, ballistics, water, cold, sand-storms) demands better textiles. b. Sports continue to require lighter and stronger textiles (ropes, poles, racquets, skis, boards, uniforms). c. Medical textiles used both inside and outside the body are required to be absorbable, antibiotic, antimicrobial, durable, selfdecontaminating, and comfortable. d. Industrial textiles require better filters, road-building fabrics, geotextiles, and textiles for spaceships and communication systems. e. The ability to reuse or recycle the textiles of tomorrow continues to challenge the textile inventor and entrepreneur. “Smart fibers of the future will inform or assist the wearer. Potential applications include clothes that monitor the medical condition of the wearer, that warn of the presence of toxic chemicals, or that adjust to suit the wearer’s environment.”1 “High-performance mirrors have been formed into hair-thin fibers and woven into fabrics or even paper. The mirror fibers could create clothing and documents with advanced capabilities. Future fabrics woven with the mirror fibers and other materials, for example, could create clothes that reflect and protect against invisible microwaves and radiation. And depending on how the mirror fibers are developed, they might even lead to clothes that can change colors like a chameleon.”2 Government regulations a. The Wool Products Labeling Act (1939) provides that all garments made of wool have a label indicating the percentage and kind of wool used. b. The Textile Fiber Products Identification Act (1958) requires that all clothing have a label listing the generic fiber content by percentage. Fashion Merchandising D-8 c. The Flammable Fabrics Act (1953) regulates the sale of highly flammable fabrics used in apparel and prohibits the sale of extremely flammable fabrics. d. The Permanent Care Labeling Act (1972) requires that all clothing offered for sale in retail stores have a label indicating specific care instructions. New symbols for use in this labeling were introduced in 1997. _______________ 1 Dr. Niall Finn, Account Manager, Technical Textiles, CSIRO Textile and Fibre Technology. Niall.finn@tft.csiro.au http://retailindustry.about.com/cs/lookingforward/ http://retailindustry.about.com/gi/dynamic/offsite.htm?site=http%3A%2F%2 fwww.tft.csiro.au%2Ftextile_news%2Fcurrent%2Ftnfuturetex.html 2 Massachusetts Institute of Technology. Information from the Web http://www.scienceblog.com/community/older/2002/E/20023580.html http://web.mit.edu/newsoffice/index.html Fashion Merchandising D-9