Thermodynamics Exam: Vapor Power Cycles & Feedwater Heaters

advertisement

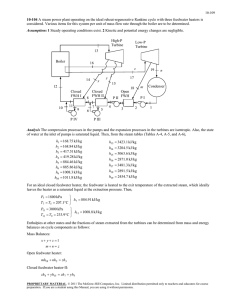

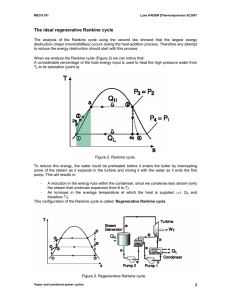

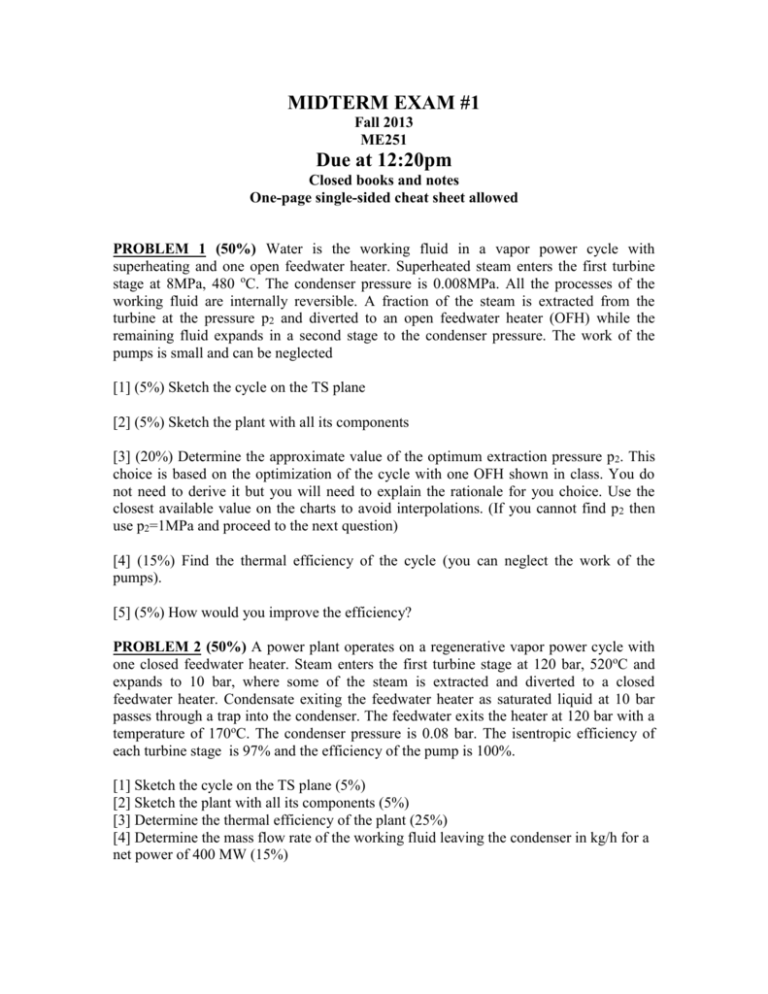

MIDTERM EXAM #1 Fall 2013 ME251 Due at 12:20pm Closed books and notes One-page single-sided cheat sheet allowed PROBLEM 1 (50%) Water is the working fluid in a vapor power cycle with superheating and one open feedwater heater. Superheated steam enters the first turbine stage at 8MPa, 480 oC. The condenser pressure is 0.008MPa. All the processes of the working fluid are internally reversible. A fraction of the steam is extracted from the turbine at the pressure p2 and diverted to an open feedwater heater (OFH) while the remaining fluid expands in a second stage to the condenser pressure. The work of the pumps is small and can be neglected [1] (5%) Sketch the cycle on the TS plane [2] (5%) Sketch the plant with all its components [3] (20%) Determine the approximate value of the optimum extraction pressure p2. This choice is based on the optimization of the cycle with one OFH shown in class. You do not need to derive it but you will need to explain the rationale for you choice. Use the closest available value on the charts to avoid interpolations. (If you cannot find p2 then use p2=1MPa and proceed to the next question) [4] (15%) Find the thermal efficiency of the cycle (you can neglect the work of the pumps). [5] (5%) How would you improve the efficiency? PROBLEM 2 (50%) A power plant operates on a regenerative vapor power cycle with one closed feedwater heater. Steam enters the first turbine stage at 120 bar, 520oC and expands to 10 bar, where some of the steam is extracted and diverted to a closed feedwater heater. Condensate exiting the feedwater heater as saturated liquid at 10 bar passes through a trap into the condenser. The feedwater exits the heater at 120 bar with a temperature of 170oC. The condenser pressure is 0.08 bar. The isentropic efficiency of each turbine stage is 97% and the efficiency of the pump is 100%. [1] Sketch the cycle on the TS plane (5%) [2] Sketch the plant with all its components (5%) [3] Determine the thermal efficiency of the plant (25%) [4] Determine the mass flow rate of the working fluid leaving the condenser in kg/h for a net power of 400 MW (15%)