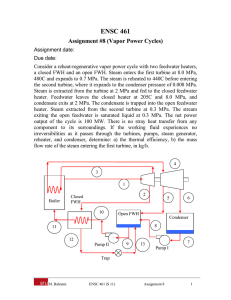

HW 5 part2 Solutions

advertisement

ASEN 3113 Thermodynamics and Heat Transfer Homework #5 Assigned: October 12, 2006 Due: October 19, 2006 (class time) (Total points noted in each section; must clearly show equations with values and units, drawings, assumptions, etc.) 1. (20 points, 15 points for equations, 5 points for correct answer) A cold storage room is being used to store strawberries at 1°C. The evaporator and condenser temperatures are -2 and 45°C, respectively. The refrigeration load is 15 tons (1 ton of refrigeration load = 3.517 kW). Assume the refrigerant is R-134a. Determine the following: (a) The refrigerant flow rate (b) The compressor power requirement (c) COP (d) The heat rejected in the condenser 2. (20 points, 15 points for equations, 5 points for correct answer) For a refrigeration system using R -134a, the evaporator temperature is -5°C, however the refrigerant entering the compressor is at 5°C. The condenser temperature is 35°C, but the refrigerant entering the expansion valve is at 30°C. (a) What is the amount of superheating and subcooling? (b) If the refrigeration load is 3 tons, calculate the COP for this system. 3 (20 points, 15 points for equations, 5 points for correct answer) A turbojet aircraft is flying with a velocity of 220 m/s at an altitude of 5800 m. The pressure ratio across the compressor is 14, and the temperature at the turbine inlet is 1440 K. Assume ideal operations for all components and ideal gas constant specific heats at the altitude temperature. Determine the following: (a) The pressure at the turbine exit (b) The velocity of the exhaust gases (c) The propulsive efficiency 4 (20 points, 15 points for equations, 5 points for correct answers) Consider a 100 MW steam power plant operating as an ideal rankine cycle. The condenser pressure is 8kPa. The turbine can operate at two pressures, 18 MPa or 4 MPa. Determine for each of the turbine pressures: (a) Mass flow rate of steam (b) Heat transfer rate of the working fluid passing through the condenser and boiler. (c) Thermal efficiency Soln: For the cycle the net power output is w cycle w t w p m h1 h2 (h4 h3 ) , Thus m w cycle (h1 h2 ) (h4 h3 ) The working fluid passing throough the boiler experiences heat transfer at a rate Q in m (h1 h4 ) and in the condenser Q out m (h2 h3 ) The thermal efficiency of the cycle is w cycle Q in a) P1=18 Mpa State 1: P1 = 18MPa, saturated vapor h1=2509.1 KJ/kg, s1=5.1044 KJ/kg s2 s f 0.591, h2 1594.1kJ State 2: P2 = 8kPA, s2=s1 sg s f State 3: P3 = 8kPa, saturated liquid h3=173.88 kJ/kg State 4: h4 = h3 + v3(P4-P3); h3 = 173.88 kJ/kg, v3 = 1.0084x10-3 m3/kg h4 = 192.02 kJ/kg Therefore m w cycle (h1 h2 ) (h4 h3 ) = 4.014x105kg/h And Q in m (h1 h4 ) = 258.4x103kW And Q out m (h2 h3 ) = 158.4x103 kW Therefore w cycle = 0.387 Q in b) P1= 4 Mpa State 1: P1 = 4MPa, saturated vapor h1=2801.4 KJ/kg, s1=6.0701 KJ/kg s2 s f 0.7173, h2 1897.6kJ State 2: P2 = 8kPA, s2=s1 sg s f State 3: P3 = 8kPa, saturated liquid h3=173.88 kJ/kg State 4: h4 = h3 + v3(P4-P3); h3 = 173.88 kJ/kg, v3 = 1.0084x10-3 m3/kg h4 = 1177.91 kJ/kg Therefore m w cycle (h1 h2 ) (h4 h3 ) = 4.001x105kg/h And Q in m (h1 h4 ) = 291.6x103kW And Q out m (h2 h3 ) = 191.6x103 kW Therefore w cycle = 0.343 Q in 5 (20 points, 15 points for equations, 5 points for correct answers) (a) A steam power plant is operating as a regenerative vapor power cycle with one closed feedwater heater that tap off between the first and second turbine stages. The turbine inlet conditions are pressure 12 Mpa, temperature 510 C. Condenser pressure is 6 kPa. Boiler inlet temperature is 170 C. Work of the cycle is 320 MW. Determine: (a) Thermal efficiency (b) Mass flow rate into the turbine first stage Assumptions: (1) Each component is analyzed as a control volume at steady state. (2) All processes are internally reversible except fro the expansion through the trap (throttling process) and in the closed feedwater heater. (3) Turbines, pump, and feedwater heater operate adiabatically. (4) Kinetic and potential energy functions are negligible. (5) Condensate exists in the condenser and closed heater as saturated liquid at the respective pressures. 1 bar = 100kPa Soln: Fix each of the principal points. State 1: P1 = 12 MPa, T1 = 520 C h1 = 3401.8 kJ/kg, s1 = 6.5555 kJ/kg K State 2: P2 = 1 MPa, s1 = s2 χ2 = 0.9931, h2 = 2764.2 kJ/kg State 3: P3 = 6 kPa, s3 = s1 χ3 = 0.7727, h3 = 2018.3 kJ/kg State 4: P3 = 6 kPa, saturated liquid h4 = 151.53 kJ/kg State 5: h5 = h4 + v4(P5-P4), v4 = 1.0064x103 m3/kg 163.6kJ/kg State 6: P6 = 12 MPa, T6 = 170 C h6 = 725.86 kJ/kg State 7: P7 = 1 MPa, sat liquid h7 = 762.81 kJ/kg State 8: Throttling Process h8 = h7 = 762.81 kJ/kg a) Applying mass and energy rate balances to the control volume surrounding the closed feedwater heater, the fraction of flow y extracted at location 2 is; h6 h5 0.2809 h2 h7 For the control volume surrounding the turbine stages y w t (h1 h2 ) (1 y)( h2 h3 ) 1174.0kJ / kg m 1 And for the pump w p (h5 h4 ) 12.07kJ / kg m 1 For the working fluid passing through the steam generator Q in (h1 h6 ) 2675.9kJ / kg m 1 Thus the thermal efficiency is w t w p m m 1 1 Q in m 1 0.434 (b) The mass flow rate into the first turbine stage is found from: m 1 w cycle w t w p m 1 m 1 9.91x10 5 kg / h