ME-251 FINAL EXAM (Fall 1997)

advertisement

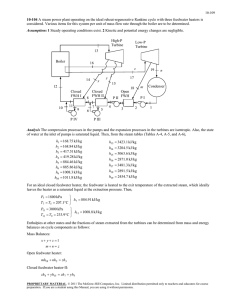

ME -251 MIDTERM EXAM (Fall 2009 - Instructor: R. Betti) Closed books and closed notes One single-page one-sided cheat sheet is allowed Due at 12:20 pm Water is the working fluid in a vapor power cycle with superheating, reheating, one open feedwater heater and one closed feedwater heater. The steam generator pressure is 8MPa and the condenser pressure is 0.008MPa. All the processes of the working fluid are internally reversible. The temperature of the superheated steam at the high-pressure turbine inlet is T1 =480 oC. A fraction of the steam is extracted from the high-pressure turbine at the pressure of 2 MPa and diverted to a closed feedwater heater (CFH) while the remaining steam expands to 1MPa. The steam at the outlet of the high pressure turbine is reheated at constant pressure (of 1MPa) to 500 oC in the steam generator and sent to the low pressure turbine. A fraction of the fluid is extracted at 0.5MPa from the low pressure turbine and used in the open feed-water heater while the remaining fluid expands in the low pressure turbine to the condenser pressure. The feedwater leaving the condenser is pumped to the OFH at 0.5 MPa and leaves as saturated liquid. It is then pumped to 8MPa into the CFH where it is heated to 200 oC. After leaving the CFH, the feedwater goes to the steam generator. The condensate (saturated liquid at 2MPa) from the first extraction in the CFH streams through traps into the OFH. (15%) Sketch the thermodynamic cycle in the T-S plane (15%) Sketch the layout of the plant including all the components (30%) Determine the cycle efficiency (15%) Determine the back work ratio (15%) If the mass flow rate of steam entering the high pressure turbine is 2.6 105kg/h, determine the net power in KW (10%) Determine the rate of heat transfer to the cooling water in the condenser in MW.