19 April 2012 Keith Mitchell – Productivity Benchmarking

advertisement

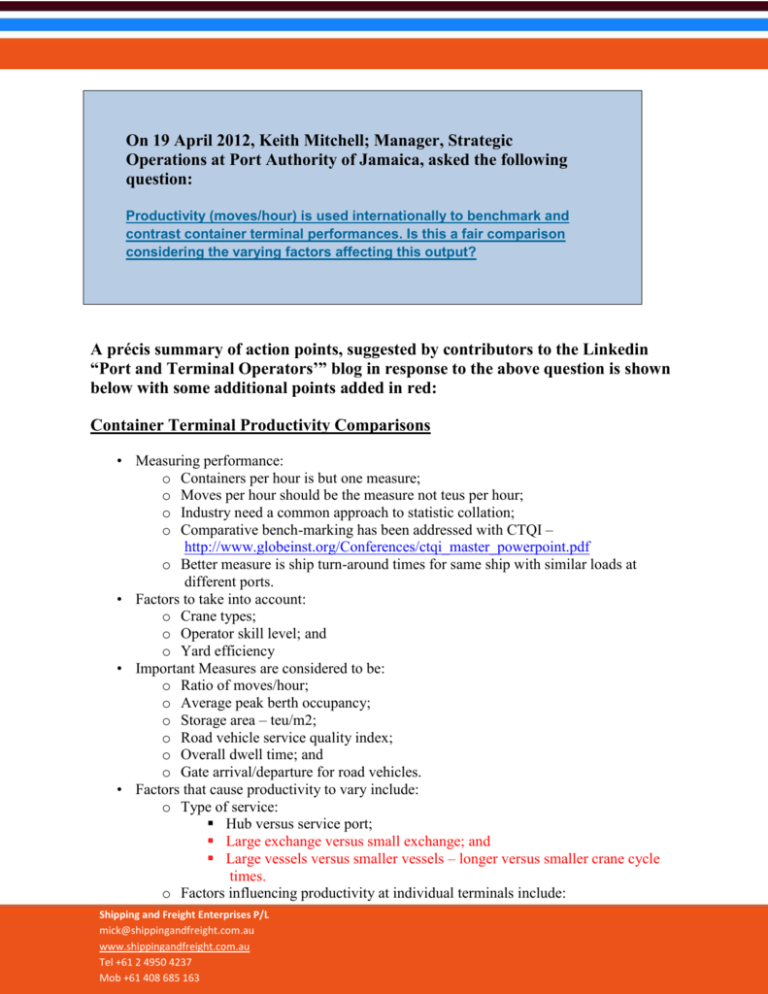

On 19 April 2012, Keith Mitchell; Manager, Strategic Operations at Port Authority of Jamaica, asked the following question: Productivity (moves/hour) is used internationally to benchmark and contrast container terminal performances. Is this a fair comparison considering the varying factors affecting this output? A précis summary of action points, suggested by contributors to the Linkedin “Port and Terminal Operators’” blog in response to the above question is shown below with some additional points added in red: Container Terminal Productivity Comparisons • Measuring performance: o Containers per hour is but one measure; o Moves per hour should be the measure not teus per hour; o Industry need a common approach to statistic collation; o Comparative bench-marking has been addressed with CTQI – http://www.globeinst.org/Conferences/ctqi_master_powerpoint.pdf o Better measure is ship turn-around times for same ship with similar loads at different ports. • Factors to take into account: o Crane types; o Operator skill level; and o Yard efficiency • Important Measures are considered to be: o Ratio of moves/hour; o Average peak berth occupancy; o Storage area – teu/m2; o Road vehicle service quality index; o Overall dwell time; and o Gate arrival/departure for road vehicles. • Factors that cause productivity to vary include: o Type of service: Hub versus service port; Large exchange versus small exchange; and Large vessels versus smaller vessels – longer versus smaller crane cycle times. o Factors influencing productivity at individual terminals include: Shipping and Freight Enterprises P/L mick@shippingandfreight.com.au www.shippingandfreight.com.au Tel +61 2 4950 4237 Mob +61 408 685 163 Type of ship; Contract requirements; Type of crane; Rated capacities of cranes in each move; Operator productive time on the machine; Potential for twin or quad moves; Efficiency of yard management and TOS; Yard geometry; Level of automation; Yard management; Number of terminal moves per containers handled; Ship container stow lashing and twist-lock systems; Handling of empties including pre-stacking; and Efficiency limited by cost. o Further complicating factors: Size of vessels; Size of exchanges; High proportion of deck stows with twist-locks; Multiple stows; Cargo dispositions and potential for crane intensity; Number of “shifts on board”; Amount of non-containerized cargo; Hatch lid moves; Ship-board cranes; Position of accommodation block; Need to shift cranes round accommodation and cranes; Speed of boom lifting on STS gantry cranes; Need to use of lashing cages; and Departures controlled by tides. Expected outcomes: o Top performance suggested as 140 moves per hour for latest very large container vessels; o Performance adjustment must be made for: Ship or yard constraints, work rules, etc.; Container stow situations e.g.: Number of exchanges per crane position; Deck stow – shorter crane cycle distance but twist lock handling; Under –deck stow – longer crane cycle distance, cell entry, no twist-locks; and Under –deck stow – longer crane cycle distance, no cell entry but twist-lock handling; Terminal Mobile Handling Equipment transferring containers to and from spreader: Straddles – disconnect crane and mobile plant operations – but need twist locks handled before containers can be landed; Shipping and Freight Enterprises P/L mick@shippingandfreight.com.au www.shippingandfreight.com.au Tel +61 2 4950 4237 Mob +61 408 685 163 Automated Guided Vehicles, (AGVs) - connects crane and mobile plant operations but more can be provided at same price as there is no labour cost; and Rubber Tyred Gantries, (RTGs) – fed by truck and trailer transfer which again connects crane and mobile plant operations but cutaway corners allow twist locks to be handled on trailers with no crane delay. Two main questions: o How close is the terminal to the current maximum productivity as defined by the ship/crane/yard/TOS interaction? o How can the maximum be raised? Answer dependent upon: o Number of straddles assigned; o Quality and motivation of the drivers; o Quality of the yard planning in the TOS (minimizing straddle distance etc.) o Potential for strategic improvements such as: twin pick or tandem 40 dock cranes replacing single move cranes, new TOS rules to allow for more sophisticated vehicle pooling, better ship stows that may allow for more moves per hatch, more twin picks or cycle moves, larger ships that transition from geared to dedicated container vessels; changes in the yard to move from a pure straddle operation to, for instance, an RMG plus straddle or other operation. 120704 For more ideas as to how to improve terminal operations contact Shipping and Freight Enterprises Pty Ltd for assistance. Shipping and Freight Enterprises P/L mick@shippingandfreight.com.au www.shippingandfreight.com.au Tel +61 2 4950 4237 Mob +61 408 685 163