Quiz 3 Summer 1995

advertisement

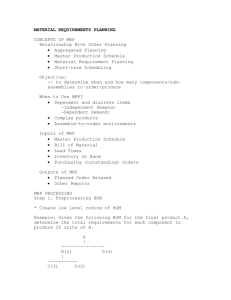

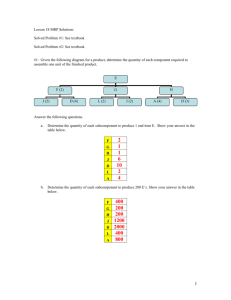

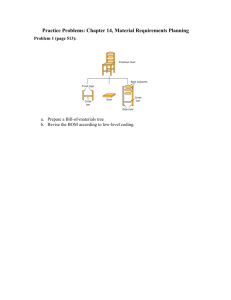

Quiz for MRP (46pts total) Fall 2001 Name ________________________________ ID ___________________________________ ______ In the MRP process, the gross requirement of the finished product is derived from a. demand forecast of the components b. demand forecast of its parent product c. the master production schedule of itself d. planned order release of its components I. Concept Questions (26pts) ______ Aggregated planning is a production planning for a. a product family b. an individual product c. components of a product d. all of the above ______ Demand of a finished product is usually considered as dependent demand. ______ Which of the following is NOT an input of MRP? a. Master production schedule b. Bill of material c. Lead time information d. Planned order release e. Inventory master file ______ Low level coding means a. that a final item has only a few levels in the BOM structure b. that a component item is coded at the lowest level at which it appears in the BOM structure c. the code for the lowest level in the BOM structure d. all of the above e. none of the above ______ One advantage of using MRP is that lot sizing need not be considered. ______ One disadvantage of using MRP is that the schedules of components are sensitive to changes of the schedule of the finished product. Frequent changes of schedules will cause system nervousness. II. Calculations (19 points) ______ Work orders and purchase orders are examples of planned order release. ______ Which of the following questions does timephased product structure answer for each component? a. When to order/produce? b. How many to order/produce? c. Both (a) and (b) d. Where to order/produce ______ Planned order release is nothing but the planned order receipt offset by lead time. ______ The planned order receipt should always be set equal to net requirement. ______ Lot for lot (L4L) means a. Setting net requirement equal to gross requirement b. Setting planned order receipt equal to net requirement c. Setting planned order release equal to gross requirement d. Setting planned order receipt equal to gross requirement ______ Lot for lot policy is cost effective if the setup cost is high and the holding cost is relatively low. Problem 1. (10 pts) Consider the BOM for the final product A: A | --------------------------------------------C(3) B(3) D(2) | ----------------------C(3) D(2) Based on the following ADDITIONAL information, determine the planned-order-release using Lot-for-Lot policy for final product A and components B and C using the tables provided on the next page (1) The master production schedule for product A Period Gross Req 7 30 8 20 9 50 10 40 (2) The lead time information for each component and the finished product Item Lead T. A 1 B 2 C 3 D 2 (3) The inventory on hand and scheduled receipts for each components: Item A Inv. on Hand 20 B 30 C 10 D 0 Sch. Receipts 20 at Period 3 50 at Period 2 60 at Period 6 0 Problem 2. (8pts) The net requirements for a component is given by the following table: Period Net Req 1 8 2 14 3 10 4 12 5 5 6 15 b. (3pts) What is the total cost associated with the PPB lot-sizing policy in (a) for the above 6 period? Show you calculation in order to get partial credit. Suppose the setup cost = $60/setup, inventory holding cost = $2/unit/period. a. (5pts) Determine the planned-order receipts based on the Part Period Balancing rule. Write your answer in the following table: Period 1 2 3 4 5 6 Net Req 8 14 7 12 5 15 PO Rec. Inventory Show your calculations to get partial credit. c. (2pts) What would be the total cost associated with the lot-for-lot policy? Item Infor A Item Infor B Item Infor C 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned-order Receipts Planned-order Releases Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned-order Receipts Planned-order Releases Gross Requirements Scheduled Receipts Projected on hand Net Requirements Planned-order Receipts Planned-order Releases