3DLevelScanner Application Data Sheet

A.P.M Automation Solutions

Email: info@apm-solutions.com

Website: www.apm-solutions.com

APM Doc # 001000 Revision # C

Check list of start-up/commissioning steps

Check the below steps to finish the start-up:

1. Check if the scanner is installed in the exact location on bin top as it was requested. If Not, add remark -

* Please indicate any change that can affect anything on scanner readings.

2. Check if the scanner is pointing out to the bin top center.

* If Not, move it to the center. If not add remark -

3. Check (while you on the bin top) for any obstacles that can be seen through any entry door inside the bin. Add remark-

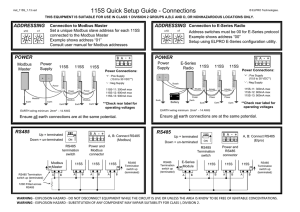

4. Check that wires (shielded & twisted pair) accessing the scanner – 2 for

()(+) 24VDC and 2 for (4…20mA / HART) or (RS485) communication

(minimum) or Both (3 pairs & ground ) according to the site needs.

5. Connect the 24VDC (& data wires accordingly –if you decided to access it from control room – if not go to step 6).

* Be sure you connect (+) to (+) and (-) to (-) according to wires colors.

6. Connect your PC with the RS485>USB convertor to the scanner.

7. Access the scanner do the following-

I. Updated F/W version.

II. Reset to factory settings

III. Run “Configuration wizard” inputs (according to IPF).

IV. Run “current simulation” – to check the analog output signal in the control room.

V. Run Communication test for RS485 (using the coonection test feature in the 3DLevelManager – go to “Device” > “Manual connect” >(check the right setup) and >>>Connect )

* In muti-drop connection

– check and access all scanners by choosing

“Pooling Address” >>>” Multiple” (option).

* Compare distance *with a laser meter from top bin door/ Level/ Volume readings to the 3DLevelScanner’s readings.

8. Disconnect your convertor and connect the installed wires accordingly.

9. Access the scanner using the LinkPro via GSM / GPRS (using the SIM card number).

*For your record write the SIM card’s number -

* When using

4…20mA signal there is no need to disconnect anything.

* In muti-drop connection – check all scanners and access all.

* If RS485 is used remember to reconnect the local connection.

* If RS485 is used remember to have in each end of the chain 120 ohm resistor .

Check that the LinkPro and the Scanner screws are tied so water wouldn’t enter via their sealer

10. Re set the false echoes mapping and run false echoes according to bin status.

11. Check readings at control room and compare it to what is expected.

12. Check information of

“point of contact” at control room for future check-ups.

Record this contact - Additional info -

13. Give this “point of contact” your Business card.

Page 1 of 2 * Customer Support * 25.02.2010

A.P.M Automation Solutions

Email: info@apm-solutions.com

Website: www.apm-solutions.com

APM Doc # 001000 Revision # C

14. Train the customer: a. How to use the 3DLevelManager. b. How to compare the distances and volume. c. General maintenance. d. Technical explanation on the 3DLevelScanner capabilities and technology.

15. Remember to return to Viewer Mode (when necessary)

16. Let the user know that when you are connected (Link Pro) he can’t access his RS485 connection.

17. If Link Pro is not on site, for future service issues , see if there is an option to use any remote access (WebEx ; ShowmyPC) to customer computer by getting permissions from the IT personal. Record the IT person info -

Page 2 of 2 * Customer Support * 25.02.2010